Hydrocracking method

A hydrocracking and hydrorefining technology, which can be used in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., and can solve problems such as the limitation of naphtha yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

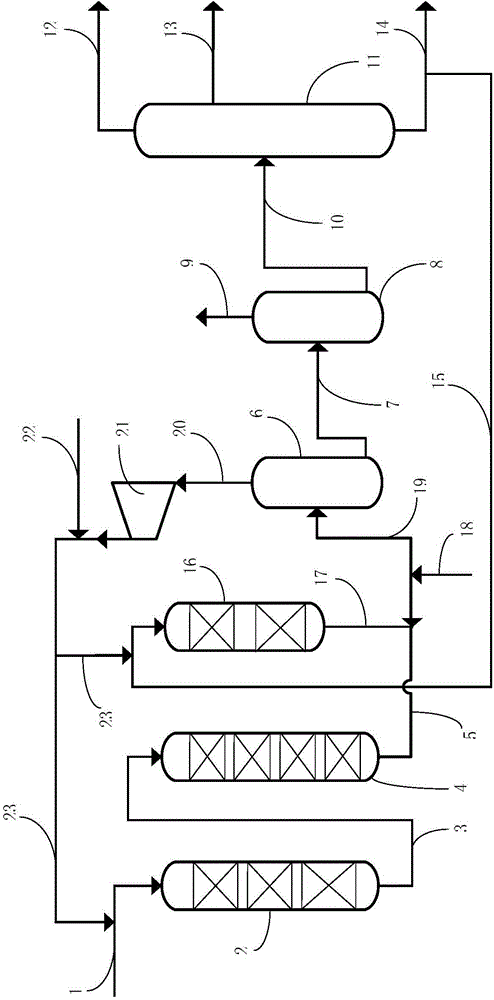

Image

Examples

Embodiment 1

[0112] In this example, the same raw material oil as Comparative Example 1 was used, and the catalyst A and catalyst B provided by the present invention were used to carry out the hydrocracking test using the process flow provided by the present invention. The experimental results are listed in Table 2-Table 4.

Embodiment 2

[0114] In this example, high nitrogen and high dry point raw material oil B was used, catalyst A and catalyst B provided by the present invention were used, and the process flow provided by the present invention was used to conduct a hydrocracking test. The experimental results are listed in Table 2-Table 4.

[0115] Table 1. Raw oil properties

[0116] Raw oil name

A

B

Density, g / cm 3

0.924

0.935

S, weight%

2.7

2.3

N, μg / g

1700

2400

Distillation range (D-1160), ℃

initial boiling point

241

318

5%

369

373

50%

469

475

90%

541

548

95%

569

572

end point

607

623

BMCI value

48.4

50.9

[0117] Table 2, comparative examples and embodiment reaction conditions

[0118] Process conditions

Comparative example 1

Example 1

Example 2

first reaction zone

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com