A kind of magnesium alloy and preparation method thereof

A magnesium alloy and master alloy ingot technology, applied in the field of metal materials, can solve problems such as imperfect research and development, limited application range, limited strength and toughness, etc., and achieve the goals of reducing hot cracking sensitivity, strong versatility, and improving comprehensive mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The industrial magnesium alloy AM50 is selected as the master alloy, the alloy is preheated to 150 ° C, and the sulfur hexafluoride SF 6 and N 2 Melt under the protection of mixed gas, raise the temperature to 720°C, preheat pure Al, pure Sn and Mg-Nd intermediate alloys and add them directly into the melt, stir and mix evenly, let stand for 10 minutes, and then put them in the metal mold Pouring in the mould. The poured castings were solid solution treated in a resistance crucible furnace at 410°C for 8 hours.

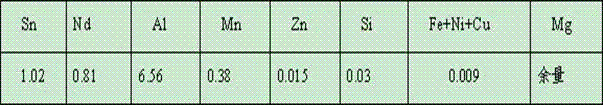

[0023] The composition of the casting obtained is shown in the following table (mass percentage):

[0024] sn

[0025] The tensile strength at room temperature is 249.6MPa, the yield strength is 168.9MPa, and the elongation is 9.5%.

Embodiment 2

[0027] Select the industrial magnesium alloy AM50 as the master alloy, preheat the alloy to 180°C, and 6 and N 2 Melt under the protection of mixed gas, raise the temperature to 720°C, preheat pure Al, pure Sn and Mg-Nd intermediate alloys and add them directly into the melt, stir and mix evenly, let stand for 15 minutes, and then place them in the metal mold Pouring in the mould. The poured castings were solid solution treated in a resistance crucible furnace at 410°C for 9 hours.

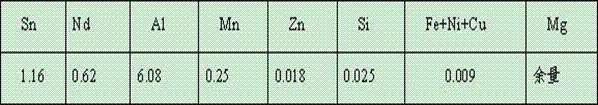

[0028] Obtain the composition of casting as follows (mass percentage):

[0029]

[0030] The tensile strength at room temperature is 235.8MPa, the yield strength is 154.7MPa, and the elongation is 10.8%.

Embodiment 3

[0032] Select the industrial magnesium alloy AM50 as the master alloy, preheat the alloy to 200°C, and 6 and N 2 Melt under the protection of mixed gas, raise the temperature to 720°C, preheat pure Al, pure Sn and Mg-Nd master alloy and add it directly into the melt, stir and mix evenly, let it stand for 20 minutes, and then put it in the metal mold Pouring in the mould. The poured castings were solid solution treated in a resistance crucible furnace at 410°C for 10 hours.

[0033] Obtain the composition of casting as follows (mass percentage):

[0034]

[0035] The tensile strength at room temperature is 242.2MPa, the yield strength is 161.7MPa, and the elongation is 10.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com