Processing method of polyester-rayon printed fabric

A processing method and fabric technology, applied in the field of textile manufacturing, can solve the problems of poor hygroscopicity of polyester fabrics, affecting comfort, and easy to carry static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

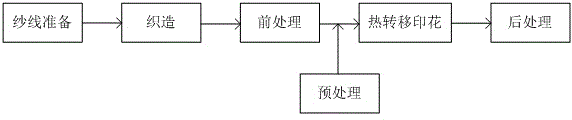

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below with the mode of embodiment, and the processing method of polyester-added rayon printed fabric comprises the following steps: yarn preparation: weft direction rayon yarn adopts common viscose fiber imitation cotton fiber length and the staple fiber of cutting is passed through airflow It is spun into 40s yarn by compact spinning, and the twist is not higher than that of conventional cotton yarn of the same yarn count, so as to achieve the soft feel of the subsequent finished fabric; the warp-oriented polyester filament adopts a fine denier of 75D / 72F.

[0027] Carry out air-jet weaving: the weaving adopts the conventional five-piece three-flying satin weaving structure, the yarn count on the upper machine is: 75D / 72F DTY*32s, the rayon density is: 105*76, and the width is 106 inches.

[0028] Pre-treatment of semi-finished gray fabrics before printing: During the pre-treatment of semi-finished products before printing, cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com