A front-end steam turbine generator room combined with a high-level arrangement of denitrification steel structure

A technology of turbo generator and steel structure, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., and can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

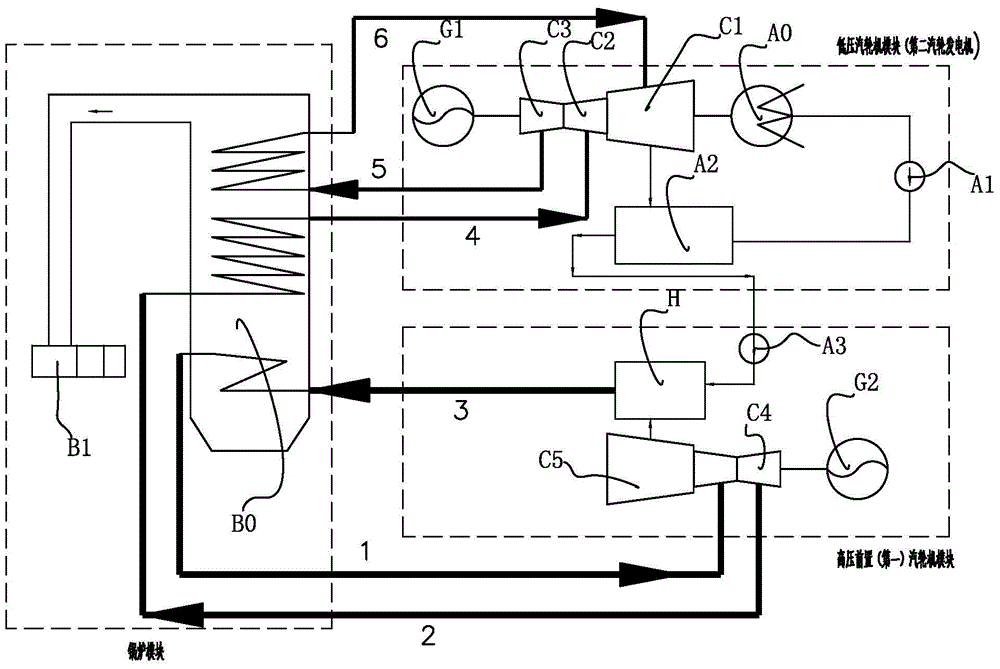

Method used

Image

Examples

Embodiment 1

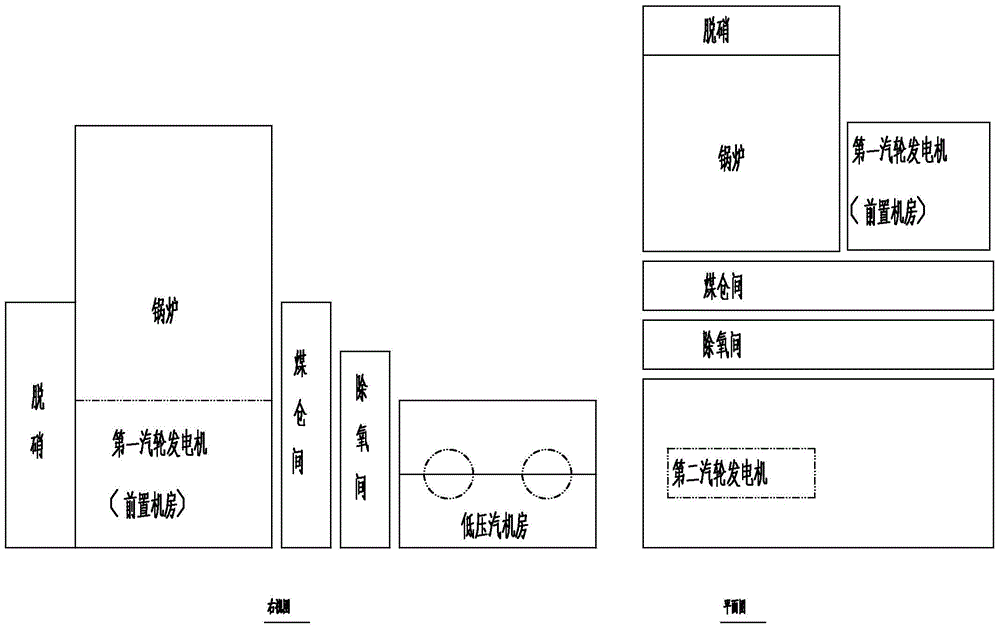

[0078] image 3 It is a structural diagram of the pre-turbine generator room combined with the denitration steel structure in the first embodiment of the present invention.

[0079] and figure 2 Compared with the shown low-level turbo-generator main workshop, the present invention transforms the denitrification steel frame into a high-level pre-turbine generator room combined with the denitrification steel structure, and the front-end unit (the high-voltage shaft system of the turbo-generator set Part) is arranged in whole or in part on the upper part of the denitrification steel frame, and the original turbo-generator set is reserved and utilized as the low-temperature and low-pressure part of the turbo-generator shafting, and is still arranged in the low-level turbine room.

[0080] The denitrified steel structure of the present invention is combined with a high-position pre-turbine generator room, including: a boiler, a coal bunker room, a deoxygenation room, a first turb...

Embodiment 2

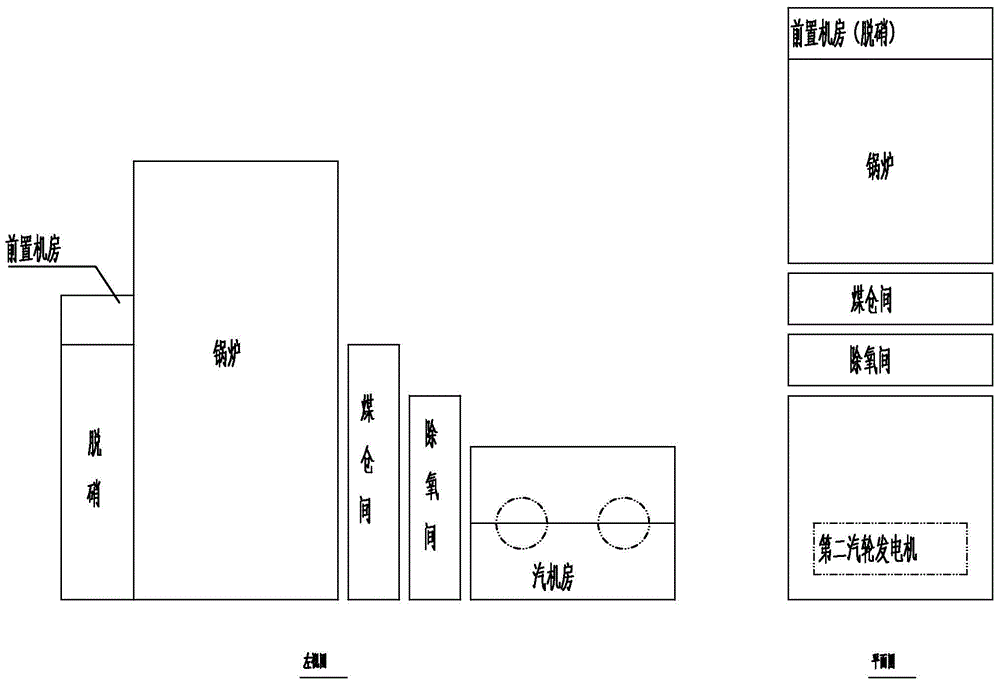

[0087] Figure 4 It is a structural diagram of the pre-turbine generator room with denitrated steel structure combined with high-level arrangement in Example 2 of the present invention.

[0088] Embodiment 2 of the present invention is similar to Embodiment 1, except that the denitrification steel frame is arranged on the side of the boiler.

[0089] The high-positioned pre-turbine generator room in this embodiment 2 can reduce the distance of the main steam pipeline by 50%-70%, and the relative length of the main steam pipeline can reach 2 / 9, and the absolute length is ≤40m. The length of the connecting piping system can be shortened to 40m, the cost of the main steam pipeline can be saved by 50%, the overall cost can be reduced by 20%, and the efficiency of the main steam pipeline can be increased by more than 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com