Hollow anti-scale oil pump

A kind of oil pump and hollow technology, applied in the direction of pump, pump components, variable capacity pump parts, etc., can solve the problem of easy access to the gap between the plunger and the pump barrel, frequent deposition, frequent fouling of the plunger of the oil pump, and difficulty in oil production in oil fields. and other problems, to prevent untimely opening and closing, highlight substantive features, and achieve the effect of cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

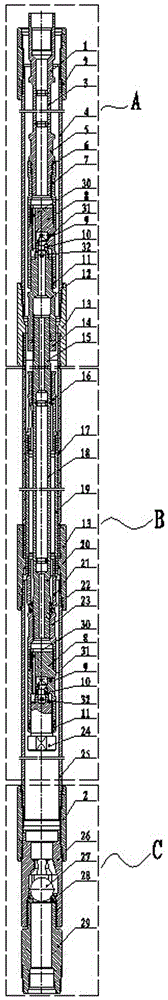

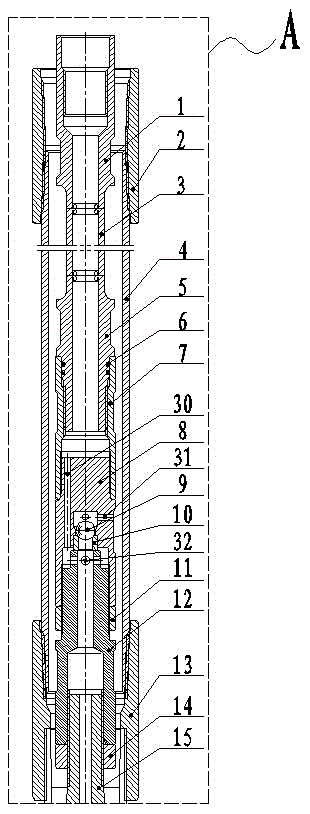

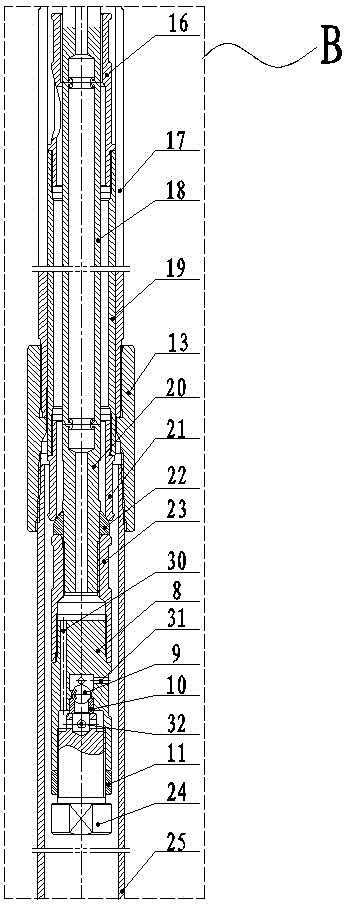

[0022] In order to clearly illustrate the technical characteristics of the present invention, the solution of the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0023] As shown in the drawings, the hollow anti-scaling oil pump provided by this embodiment includes a pump barrel assembly, a long plunger assembly and a fixed valve assembly. The pump barrel assembly includes a tubing coupling 2, an upper extended pump barrel 4. The pump barrel collar 13, the short pump barrel 17 and the lower extended pump barrel 25 below the short pump barrel 17, the two ends of the short pump barrel 17 are respectively connected to the upper extended pump barrel 4 and the lower extended pump barrel 25 through the pump barrel collar 13 connection, the lower end of the lower extended pump barrel 25 is connected with the fixed valve assembly through the oil pipe collar 2; the long plunger assembly include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com