Manufacturing method of shale rock lamina

A production method and shale technology, which is applied in the field of shale rock identification thin section, can solve the problems of interfering shale microfluorescence observation, laminar structure and combination damage, easy to damage the original structure of shale, etc., and achieve the protection of samples Effect of raw information, small sample size required, and low notch loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

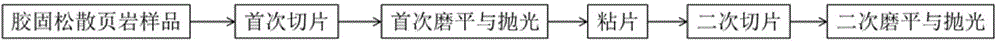

[0011] Such as figure 1 As shown, the method for making thin slices of shale rocks includes the following steps in turn: cementing loose shale rock samples; first slicing; first grinding and polishing; sticking shale samples; second slicing and second grinding Flat and polished.

[0012] For well-consolidated shale samples, the step of "cementing loose shale samples" can be omitted.

[0013] Glue the loose shale sample, the specific method is as follows: put the loose shale sample on a glass plate, drop a few drops of "502" glue on the surface of the shale sample, and let the "502" glue penetrate into the shale rock sample Medium, to saturation, wait for about 2 hours until the shale sample is cemented.

[0014] During the cementation of loose shale samples, surgical gloves should be worn to protect the skin.

[0015] The method of slicing the shale rock sample for the first time is as follows: use a Buehler low-speed precision cutting machine with a diamond cutter thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com