Acetone gas sensor based on hollow spherical ZnFe2O4 nano material and preparation method thereof

A technology of gas sensors and nanomaterials, applied in the direction of material resistance, etc., to achieve the effects of high yield, simple method, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

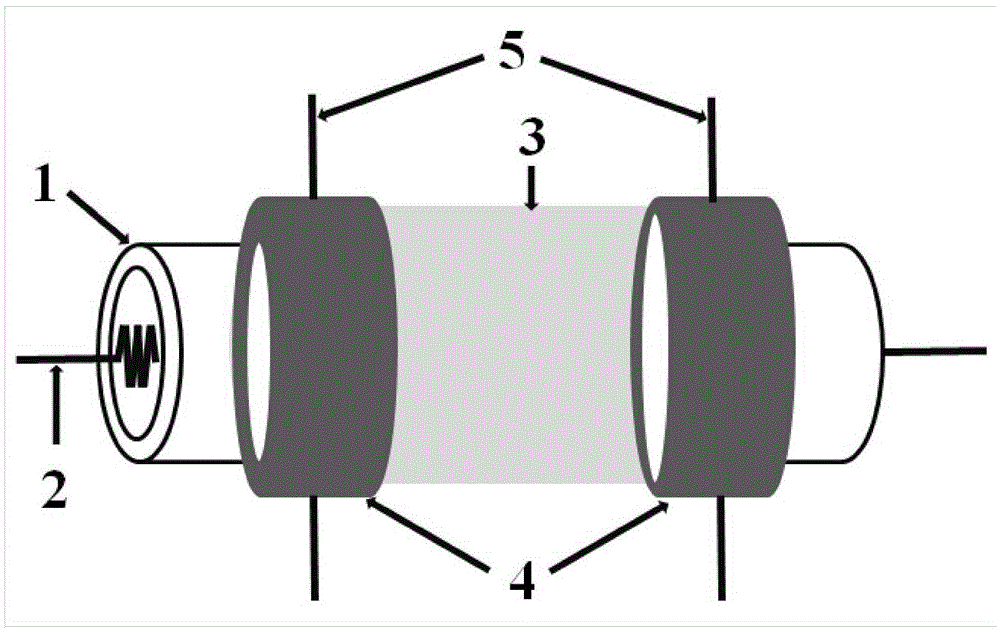

[0034] ZnFe with hollow curd 2 o 4 Nanomaterials are used to make side-heated acetone sensors, and the specific manufacturing process is as follows:

[0035] 1. First add 0.5mmol of Zn(CH 3 COO) 2 2H 2 O and 1.0mmol of Fe(NO 3 ) 3 9H 2 O was sequentially dissolved into a mixed solvent consisting of 8mL glycerin and 30mL isopropanol, and stirred for several minutes under the action of a magnetic stirrer to dissolve all the added experimental drugs.

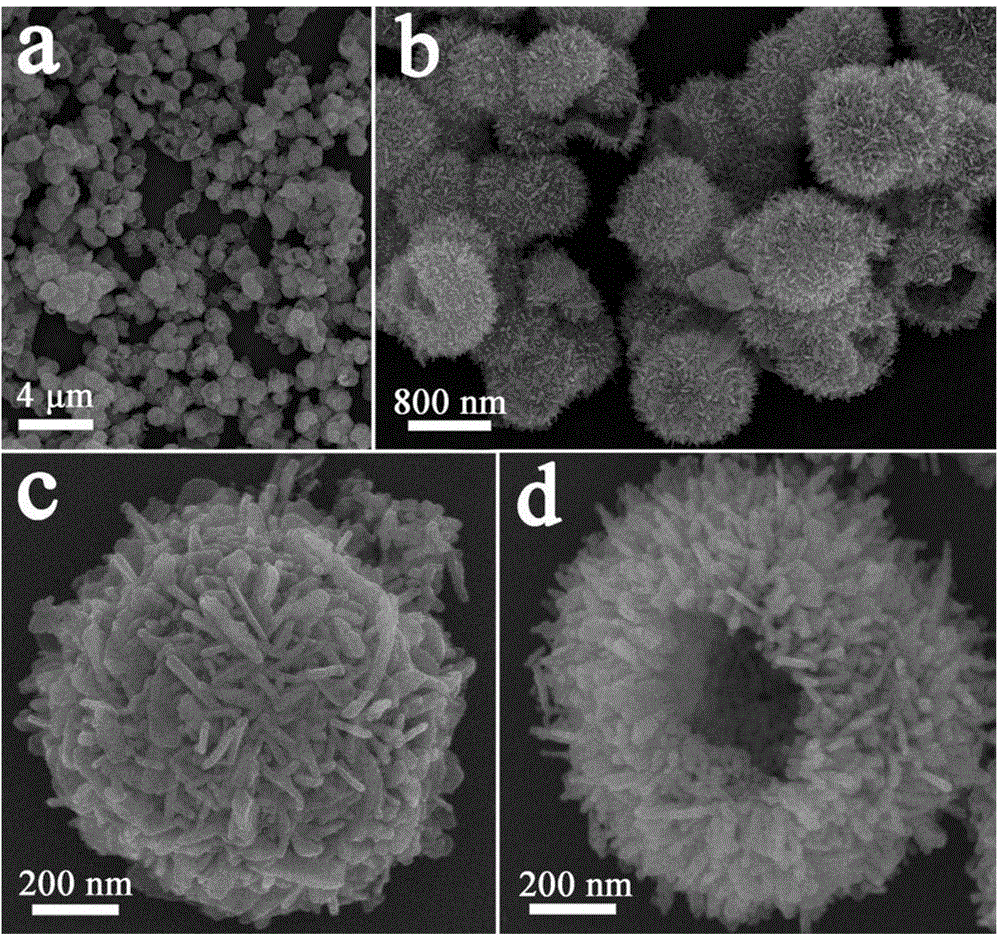

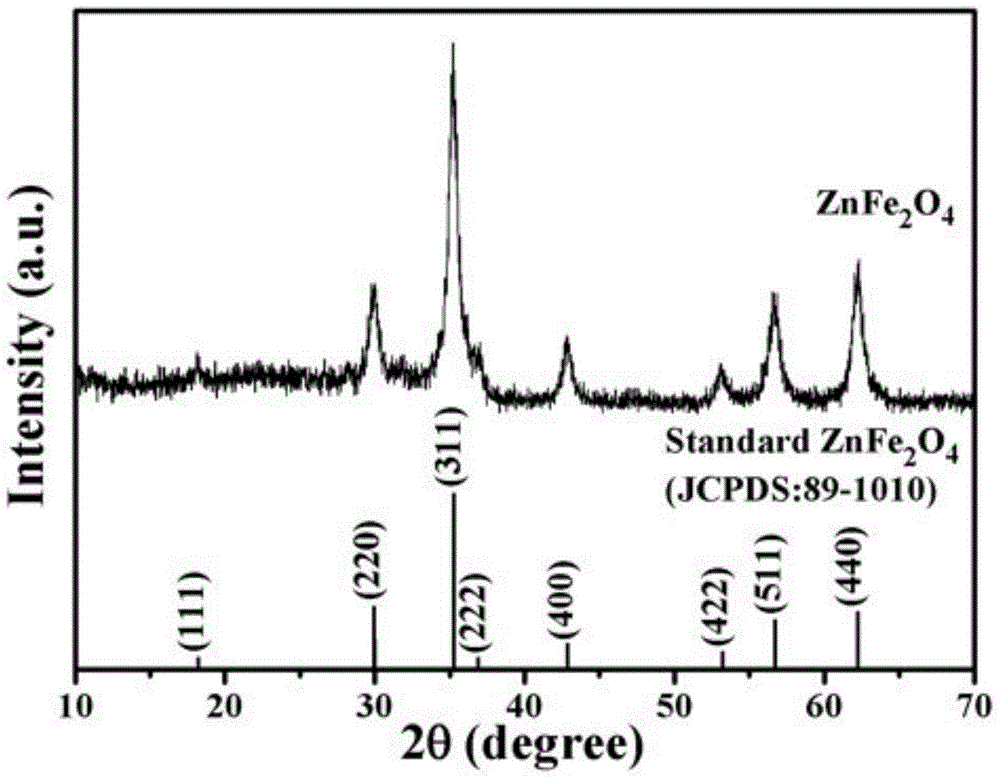

[0036] 2. Transfer the above solution to a reaction kettle with a capacity of 40mL. After the reaction kettle is tightly closed, place it in an electric heating oven at 180°C for 12 hours, then let the reaction kettle naturally cool to room temperature and separate the obtained precipitates Wash several times with ethanol and deionized water, dry at room temperature, and place the reaction precipitate in a muffle furnace at 400°C for 2 hours to obtain ZnFe nanosheets. 2 o 4 Hollow curd nanomaterials.

[0037] 3. The ZnFe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com