Novel compound feed for fish-shrimp mixed culture

A fish and shrimp polyculture and compound feed technology, applied in animal feed, animal feed, application and other directions, can solve the problems of uneven quality, poor feeding effect, poor water resistance, etc., to improve production performance, good palatability, and promote feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment adopts small water body culture, in June 2014 in Zhanjiang City Donghai Island 863 base nutrition workshop and existing fish and shrimp polyculture compound feed (market purchase, 35% crude protein, 7% crude fat) to carry out small water body comparative test, The experiment used 0.3g juvenile shrimp for 8 weeks.

[0023] Result shows: control group average feed coefficient 1.98, average end weight 6.25g, culture survival rate 80%, average ammonia nitrogen 0.725mg / L; Compound feed average feed coefficient 1.55 of the present invention, average end weight 6.5g, culture survival rate 96.3% , average ammonia nitrogen 0.711mg / L. That is to say, the bait coefficient decreased by 0.43, decreased by 27.7%, the survival rate increased by 16.3%, the final weight increased by 0.25g, and the ammonia nitrogen decreased by 1.93%.

Embodiment 2

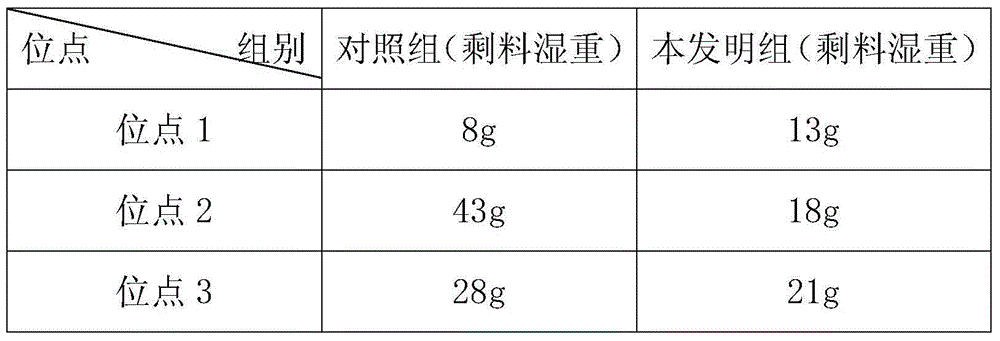

[0025] This embodiment adopts big pond culture, in June 2014 in Meiwo Village, Binhai District, Wuchuan City and existing fish and shrimp mixed culture compound feed (market purchase, 35% crude protein, 7% crude fat) to carry out food-inducing contrast test: test Weigh 1% (200g) of the feeding amount of the shrimp pond on the day and put them into round feeders (3 for each), put them into the shrimp ponds one by one, take out the feeders after 1 hour, and observe the amount of leftovers to determine the amount of feed. The food habit is good or bad, and there is less leftover material, which proves that the food attractant is good.

[0026]

[0027] The results show that: through the food attracting property, it can be found that the compound feed of the present invention can achieve better food attracting effect in the diet without fish meal and squid paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com