Nanofiber foam based oil gas trapping device and preparation method thereof

A nanofiber, oil and gas technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, to achieve the effects of improved mechanical properties and resilience, strong designability, and excellent open-pore interconnected structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

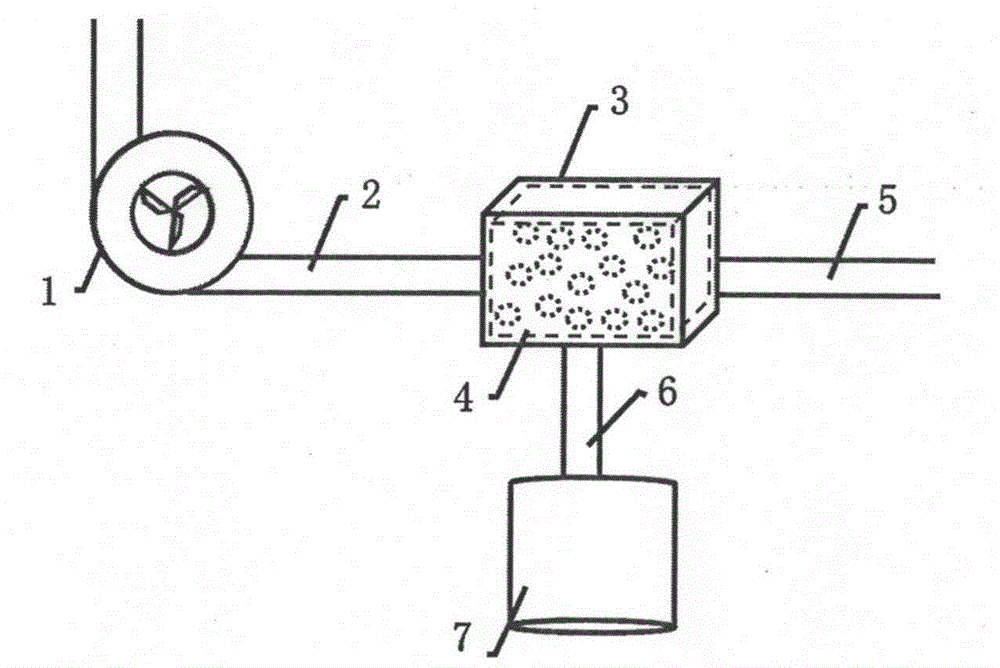

[0028] Such as figure 1As shown, it is a schematic structural diagram of a nanofiber foam-based oil and gas capture device. The nanofiber foam-based oil and gas capture device includes a gas collection pump 1 connected to a gas delivery pipe 2, and the gas delivery pipe 2 is connected to an oil and gas capture component, and the oil and gas capture component is connected to The exhaust pipe 5 and the collecting pipe 6, the collecting pipe 6 is connected to the oil substance recovery tank 7, wherein the oil and gas collection assembly includes a protective box 3, and the nanofiber-based foam material 4 is arranged in the protective box 3. The nanofiber-based foam material 4 is obtained by super-oleophilic and hydrophobic modification of the nanofiber foam material by high-voltage electrostatic spraying method. The high-voltage electrostatic spraying method adopts the EcoHT500 high-voltage electrostatic spraying system produced by German DURR company to spray super-oleophilic an...

Embodiment 2

[0036] Such as figure 1 As shown, it is a schematic structural diagram of a nanofiber foam-based oil and gas capture device. The nanofiber foam-based oil and gas capture device includes a gas collection pump 1 connected to a gas delivery pipe 2, and the gas delivery pipe 2 is connected to an oil and gas capture component, and the oil and gas capture component is connected to The exhaust pipe 5 and the collecting pipe 6, the collecting pipe 6 is connected to the oil substance recovery tank 7, wherein the oil and gas collection assembly includes a protective box 3, and the nanofiber-based foam material 4 is arranged in the protective box 3. The nanofiber-based foam material 4 is obtained by performing super-oleophilic and hydrophobic modification on nanofiber open-cell foam by using a magnetic field-induced self-assembly method. The type constant magnetic field generator applies an external magnetic field to wrap the Fe inside 3 o 4 The super-oleophilic and hydrophobic magneti...

Embodiment 3

[0044] Such as figure 1 As shown, it is a schematic structural diagram of a nanofiber foam-based oil and gas capture device. The nanofiber foam-based oil and gas capture device includes a gas collection pump 1 connected to a gas delivery pipe 2, and the gas delivery pipe 2 is connected to an oil and gas capture component, and the oil and gas capture component is connected to The exhaust pipe 5 and the collecting pipe 6, the collecting pipe 6 is connected to the oil substance recovery tank 7, wherein the oil and gas collection assembly includes a protective box 3, and the nanofiber-based foam material 4 is arranged in the protective box 3. The nanofiber-based foam material 4 is obtained by super-oleophilic and hydrophobic modification treatment on the nanofiber foam material by steam diffusion method. The colloidal silica solution is placed in a heatable closed space at the same time, the temperature of the closed space is raised to 210°C, and the internal pressure is raised to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com