A kind of impregnating device and the method for preparing catalyst

A technology of impregnation device and catalyst, which is applied in chemical instruments and methods, catalyst activation/preparation, catalysts in physical/chemical processes, etc., can solve the problems of affecting the strength of the catalyst, the large amount of carrier materials in the drum, and the difficulty in quickly dissipating the heat of adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

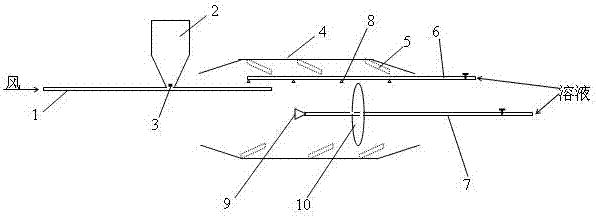

[0032] use figure 1 Impregnation apparatus shown.

[0033] The properties of the alumina carrier used are as follows: the specific surface area is 275m 2 / g, pore volume 0.75mL / g, wear index 0.51%, particle size distribution: 0.3~0.4mm accounts for 3%, 0.4~0.5mm accounts for 90%, 0.5~0.6mm accounts for 7%.

[0034] The prepared Mo-Ni-P impregnation solution is as follows:

[0035] 85.8 g of phosphoric acid H 3 PO 4 (85wt%) was dissolved in 1880 mL of water, then 232.9 g of molybdenum trioxide and 98.3 g of basic nickel carbonate were added, the temperature was raised to 100 °C, stirred and refluxed for 0.5 h, and filtered to obtain Mo-Ni-P aqueous solution.

[0036] Add 1000mL of impregnation solution to the impregnation solution feeding device, make 1 / 3 of the impregnation solution enter the rotating drum through the atomizing pipe, and the rest of the impregnating solution enter the rotating drum through the spray pipe, and 1000g of the catalyst carrier is transported by...

Embodiment 2

[0038] The prepared W-Mo-Ni-P impregnation solution is as follows:

[0039] 85.9 g of phosphoric acid H 3 PO 4 (85wt%) was dissolved in 1880 mL of water, then 116.7 g of molybdenum trioxide and 98.4 g of basic nickel carbonate were added, the temperature was raised to 100 °C and stirred and refluxed for 0.5 h to obtain a clear Mo-Ni-P solution, and then 161.4 g of partial solution was added. Ammonium tungstate, stirring to make ammonium metatungstate completely dissolved, and then filtering to obtain W-Mo-Ni-P aqueous solution.

[0040] Add 1000mL of impregnation solution to the impregnation solution feeding device, make 1 / 3 of the impregnation solution enter the rotating drum through the atomizing pipe, and the rest of the impregnating solution enter the rotating drum through the spray pipe, and take 1000g of the alumina carrier in Example 1 to pass through the catalyst. The carrier feeding device adopts gas conveying and feeding, and the gas flow rate is 2.0m / s. After the ...

Embodiment 3

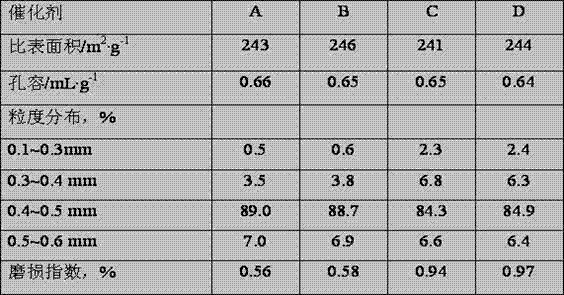

[0046] This example gives the physicochemical properties of the catalysts prepared in the above examples, see Table 1.

[0047] It can be seen from Table 1 that the catalyst prepared by the method of the present invention has a very low crushing rate and a very concentrated particle size distribution, and the catalyst of 0.4-0.5 mm accounts for more than 88%; at the same time, the catalyst prepared by this method has less wear and tear Index, good anti-wear performance, very suitable for use in fluidized bed devices.

[0048] Table 1 Physicochemical properties of different catalysts

[0049]

[0050] The method for measuring the wear index in the present invention is the method for measuring the wear index of the fluidized microsphere catalyst and the carrier (air jet wear tester method). The larger the wear index value, the worse the anti-wear performance of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com