Non-ferrous metal continuous casting-rolling-extrusion integral processing forming device and method

A non-ferrous metal, processing and forming technology, applied in the direction of metal extrusion dies, etc., can solve the problems of small plastic deformation, large metal shear deformation, and coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

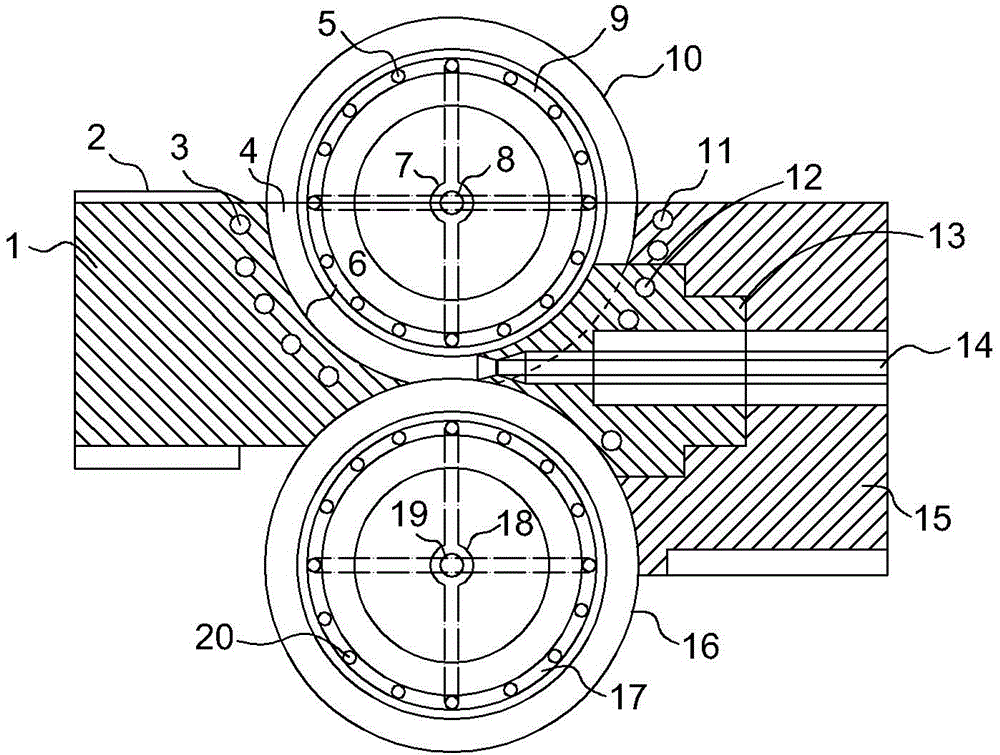

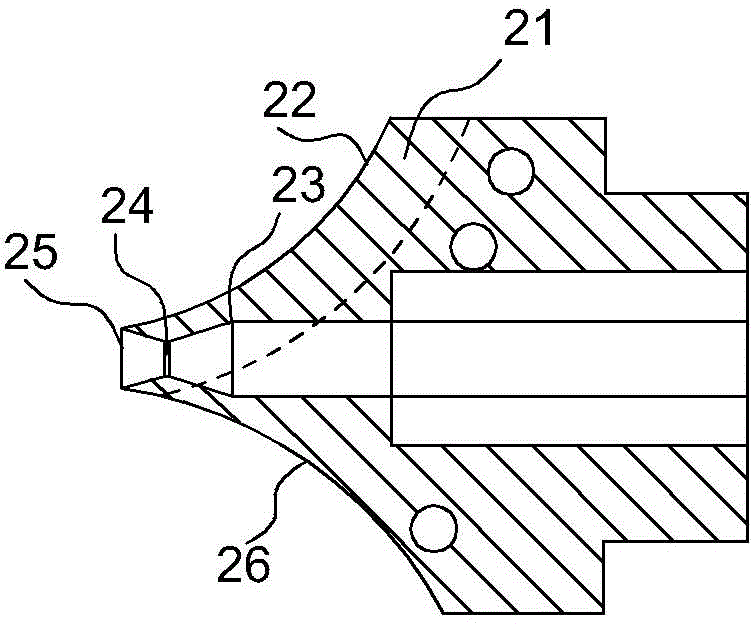

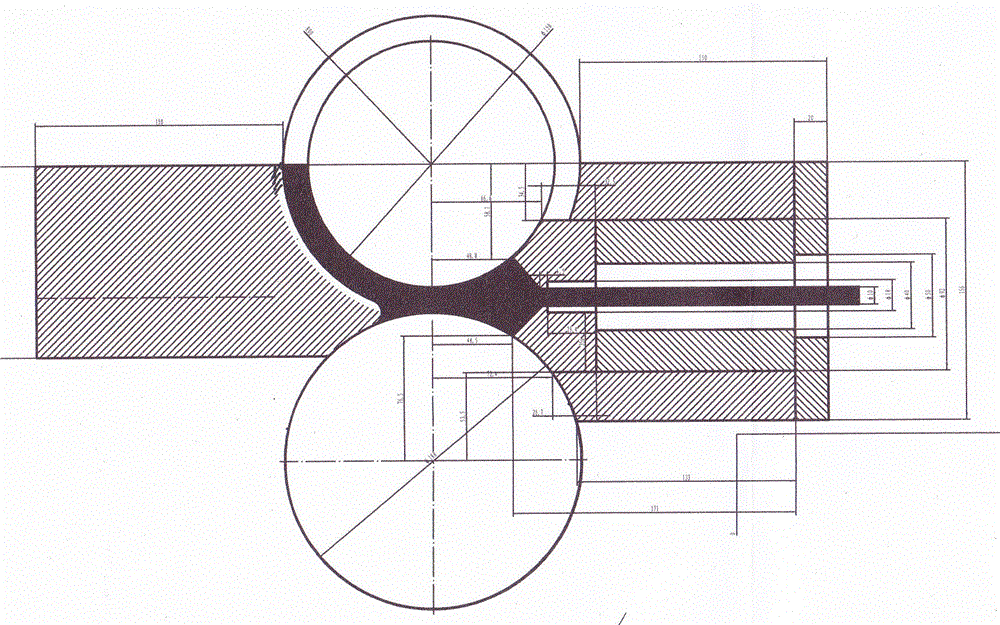

[0033] Such as Figure 1-2 As shown, the continuous casting-rolling-extrusion integrated processing molding of the present invention includes a frame, a casting extrusion shoe 1, an extrusion molding device 15, a concave roller 10, a convex roller 16, a driving mechanism and a cooling system; a casting extrusion shoe 1 and an extrusion molding The devices 15 are respectively fixed on the frame, and the extrusion molding device 15 is provided with an extrusion die 13, and the concave roller 10 and the convex roller 16 driven by the driving mechanism (the outer diameters of the concave roller and the convex roller are the same) are located in the casting extrusion Between the shoe 1 and the extrusion die 13, the concave roller 10 is on the top and the convex roller 16 is on the bottom, and the connecting line between the centers is perpendicular to the horizontal plane.

[0034] The right side of the casting extrusion shoe 1 is respectively provided with an upper arc-shaped groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com