A control method of the automatic tension hydraulic control system of the cable winding and unwinding car reel

A cable unwinding and reeling technology, which is applied in hoisting devices, spring mechanisms, fluid pressure actuating devices, etc., can solve the problem of poor coordination of the cable transmission system, excessive tightness or looseness of the cable when winding the cable, It is prone to heat attenuation and other problems, and achieves the effect of simple structure, good fit, and prevention of damage caused by suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

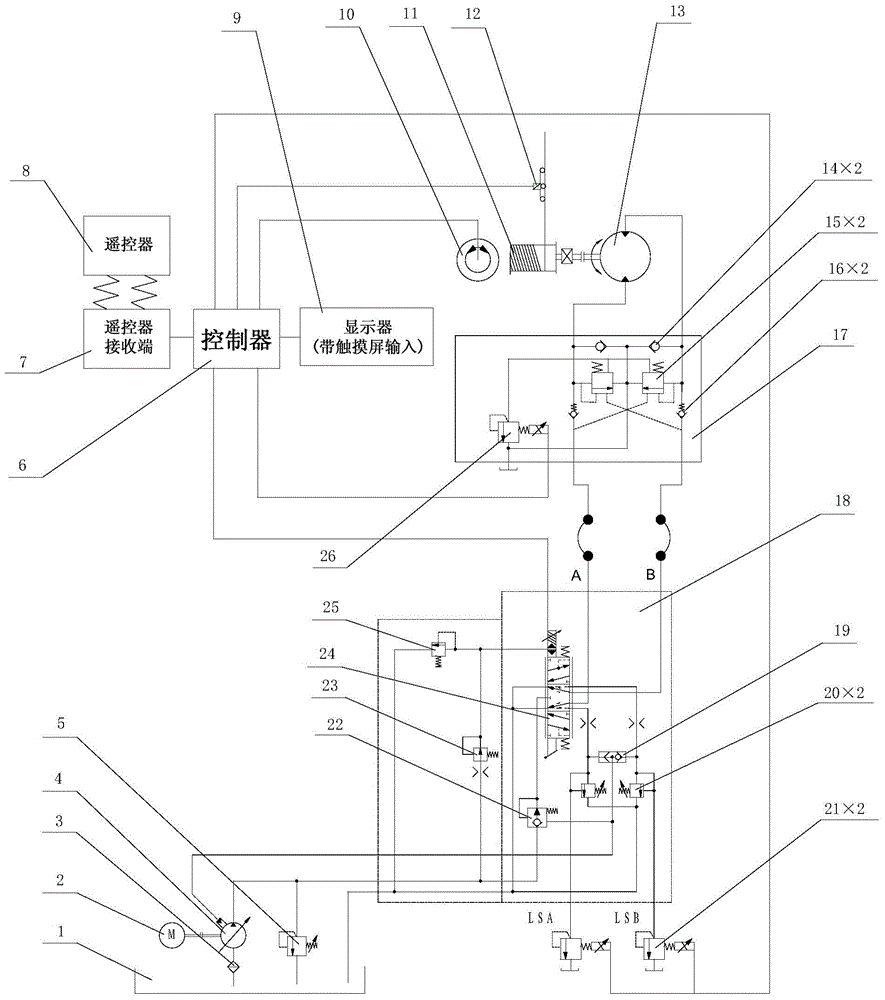

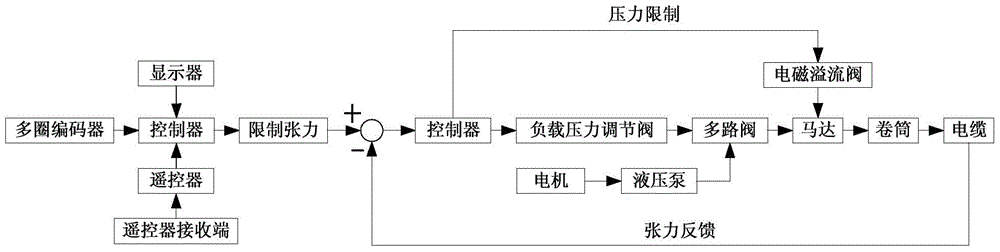

[0023] see figure 1 , an example of an automatic tension hydraulic control system for a reel of a cable winding and unwinding vehicle includes a fuel tank 1, a motor 2, a filter 3, a hydraulic pump 4, an overflow valve 5, a controller 6, a remote control receiving end 7, a remote control 8, Touch screen 9, multi-turn encoder 10, drum 11, tension sensor 12, motor 13, balance valve group 17, multi-way valve 18, load pressure regulating valve 21. Among them, the balance valve group 17 includes oil supply check valve 14, balance valve 15, check valve 16 and electromagnetic overflow valve 26; valve 23 and safety valves 20 and 25.

[0024] The motor 2 is connected to the hydraulic pump 4, the filter 3 is connected between the oil tank 1 and the hydraulic pump 4 to filter the pollutants in the oil, and the overflow valve 5 is connected to the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com