Preparation method for graphene

A graphene and graphene technology, applied in the field of graphene preparation, can solve the problems of harsh separation conditions, strong toxicity and volatility of reducing agent hydrazine hydrate, and achieve high safety and reliability, shortened reaction time, and simple and fast preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

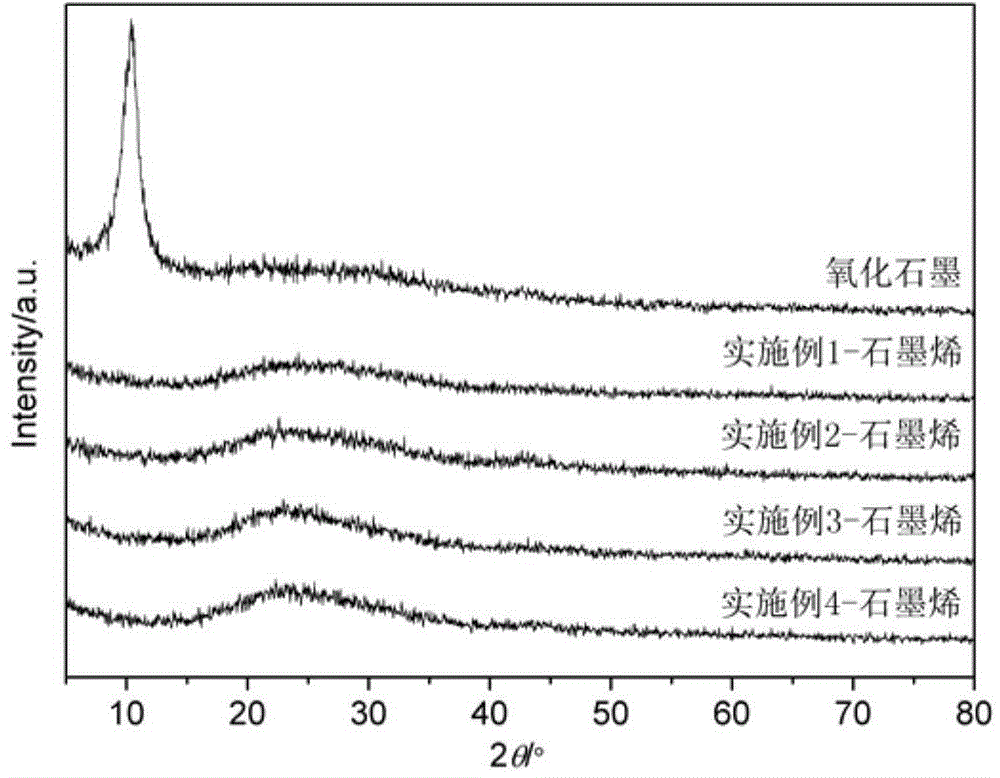

[0024] A kind of preparation method of graphene of the present invention, concrete preparation steps are as follows:

[0025] Step 1: Disperse GO with a mass concentration of 0.1-1.5 mg / mL in an aqueous solution, and ultrasonicate for 0.5-1.5 hours to form a brown-yellow graphene oxide dispersion;

[0026] In the second step, SDBS with a mass concentration of 0.05-0.25% is added to the graphene oxide dispersion liquid obtained in the first step, and ultrasonically dissolved to enhance the dispersion of graphene oxide;

[0027] In the third step, add an appropriate amount of NaOH or KOH solution to the solution obtained in the second step, and stir evenly so that the concentration of NaOH or KOH in the graphene oxide dispersion is 0.05 to 0.15 mol / L;

[0028] The fourth step is to transfer the solution obtained in the third step into a hydrothermal reactor of a certain specification, the volume filling rate of the reactor is 30-75%, and the hydrothermal reaction is carried out ...

Embodiment 1

[0031] Step 1: Disperse 55 mg of GO in 60 mL of aqueous solution, and ultrasonicate for 1 hour to form a brown-yellow graphene oxide dispersion;

[0032] In the second step, 0.1g SDBS is added to the graphene oxide dispersion obtained in the first step, and ultrasonically dissolved to enhance the dispersion of graphene oxide;

[0033] In the third step, add 5mL, 2mol / L NaOH solution to the solution obtained in the second step, and stir evenly;

[0034] The fourth step is to transfer the solution obtained in the third step into a 100mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 120°C for 3h;

[0035] In the fifth step, the product obtained in the fourth step is centrifuged and washed 5 times with deionized water at 8000 rpm for 3 minutes each time, and the obtained product is dried to obtain a graphene product.

Embodiment 2

[0037] Step 1: Disperse 20mg of GO in 60mL aqueous solution, and ultrasonicate for 0.5h to form a brown-yellow graphene oxide dispersion;

[0038] In the second step, 0.05g SDBS is added to the graphene oxide dispersion liquid obtained in the first step, and ultrasonically dissolved to enhance the dispersion of graphene oxide;

[0039] In the third step, add 2mL, 2mol / L NaOH solution to the solution obtained in the second step, and stir evenly;

[0040] The fourth step is to transfer the solution obtained in the third step into a 100mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 130°C for 4 hours;

[0041] In the fifth step, the product obtained in the fourth step is centrifuged and washed 6 times with deionized water at 10,000 rpm, and centrifuged for 4 minutes each time, and the obtained product is dried to obtain a graphene product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com