Method for preparing waste circuit board activated carbon by vapor process

A technology for waste circuit boards and board activated carbon, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of residual chemicals, waste of resources, and complex components in carbon products, so as to alleviate the shortage of raw material resources and reduce waste and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing activated carbon from waste circuit boards by water vapor method, the steps are as follows:

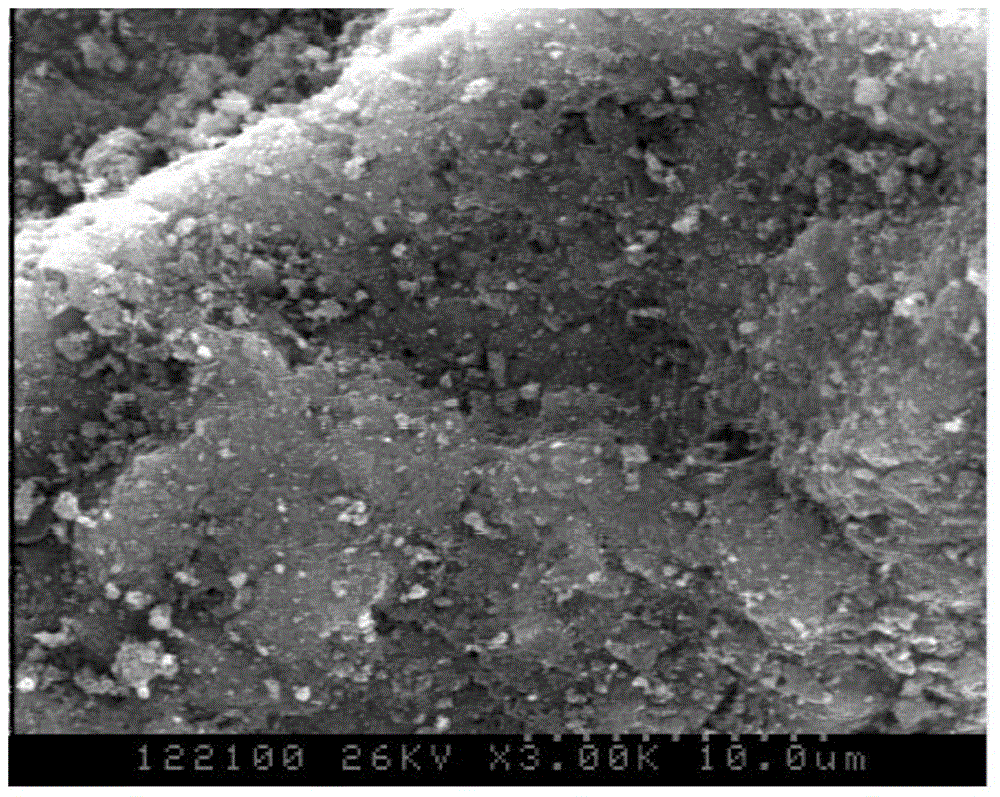

[0034] (1) After the waste circuit board is crushed, the metal and non-metal objects are separated by the specific gravity method, and the non-metal objects are crushed to a particle size of 0.2mm×0.2mm to obtain the non-metal powder of the waste circuit board;

[0035] (2) Place the non-metallic powder of waste circuit boards in a carbonization furnace, raise the temperature to 600°C at a rate of 8°C / min under anaerobic conditions, and treat at 600°C for 1.5 hours at a constant temperature to obtain carbonized waste circuit boards plate;

[0036] (3) Take the carbonized waste circuit board in step (2), and raise the temperature to 800°C at a rate of 4°C / min under the protection of water vapor, and the rate of water vapor is 0.6L / min. React at a constant temperature for 60 minutes, cool to room temperature and directly grind and sieve to obtain activated...

Embodiment 2

[0039] A method for producing activated carbon from waste circuit boards by water vapor method, the steps are as follows:

[0040] (1) After the waste circuit board is crushed, the metal and non-metal objects are separated by the specific gravity method, and the non-metal objects are crushed to a particle size of 0.2mm×0.2mm to obtain the non-metal powder of the waste circuit board;

[0041] (2) Place the non-metallic powder of waste circuit boards in a carbonization furnace, raise the temperature to 500°C at a rate of 10°C / min under anaerobic conditions, and carbonize at a constant temperature of 500°C for 2 hours

[0042](3) Take the carbonized waste circuit board in step (2), and raise the temperature to 750°C at a heating rate of 6°C / min under the protection of water vapor, and the rate of water vapor introduction is 0.8L / min. React at a constant temperature for 90 minutes, cool to room temperature and directly grind and sieve to obtain activated carbon from waste circuit ...

Embodiment 3

[0044] A kind of method for the waste and old circuit board activated carbon of water vapor legal system, as described in embodiment 1, difference is:

[0045] Step (2), put the non-metallic powder of the waste circuit board in a carbonization furnace, raise the temperature to 450°C at a heating rate of 6°C / min under anaerobic conditions, and carbonize at a constant temperature of 450°C for 3 hours

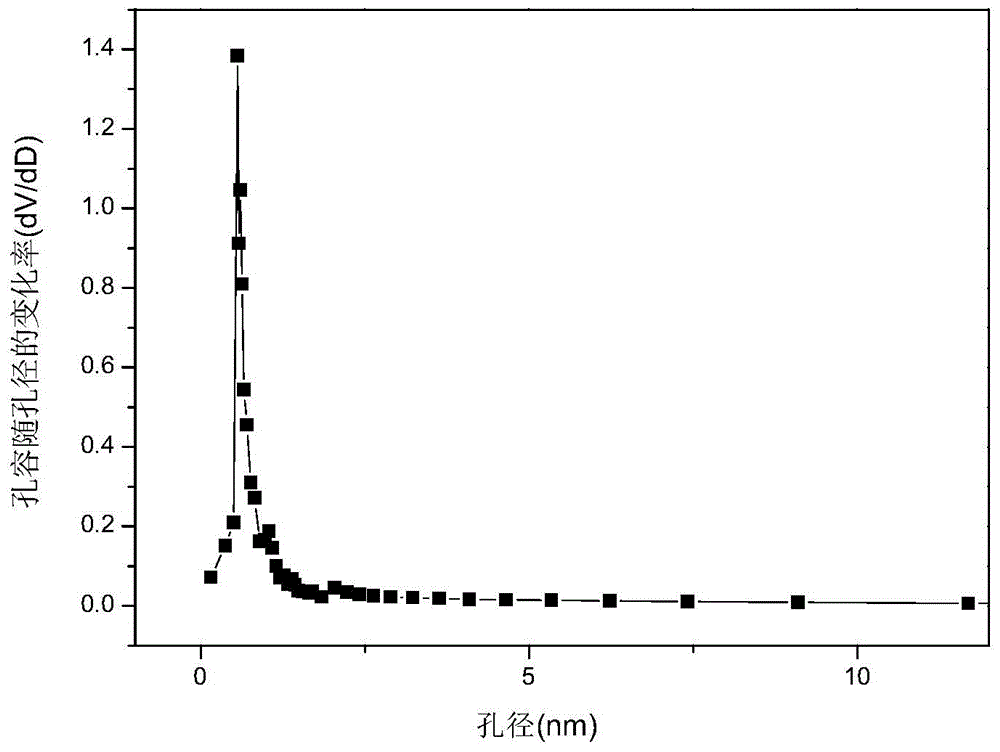

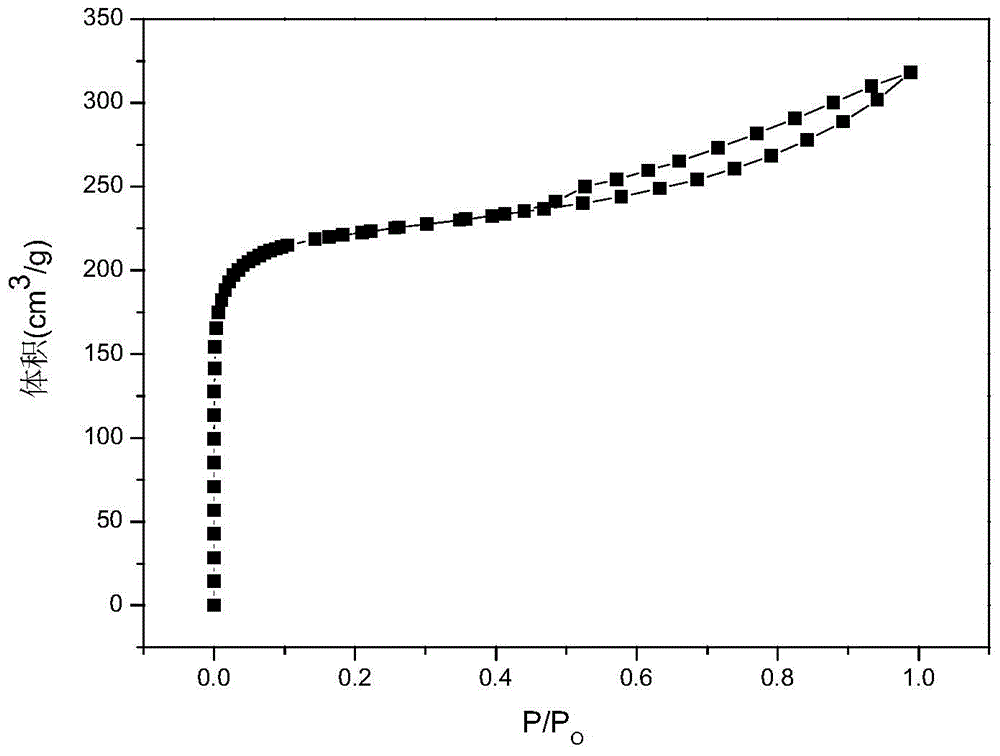

[0046] (3) Take the carbonized waste circuit board in step (2), and raise the temperature to 900°C at a rate of 8°C / min under the protection of water vapor, and the rate of water vapor is 1L / min. React at a constant temperature for 30 minutes, cool to room temperature, and directly grind and sieve to obtain activated carbon from waste circuit boards. The prepared activated carbon has a specific surface area of up to 705m 2 / g. The methylene blue adsorption amount was 302 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com