Method for reducing energy consumption in the process for separation of 1,3-pentadiene from petroleum cracking C5 fraction

A piperylene and petroleum cracking technology, applied in chemical instruments and methods, hydrocarbon purification/separation, hydrocarbons, etc., can solve the problem of high energy consumption and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

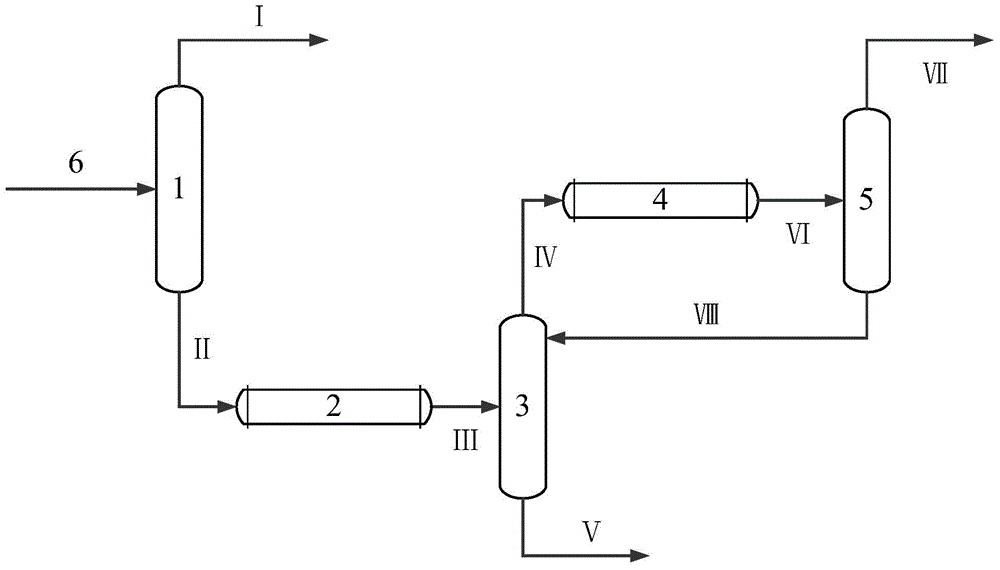

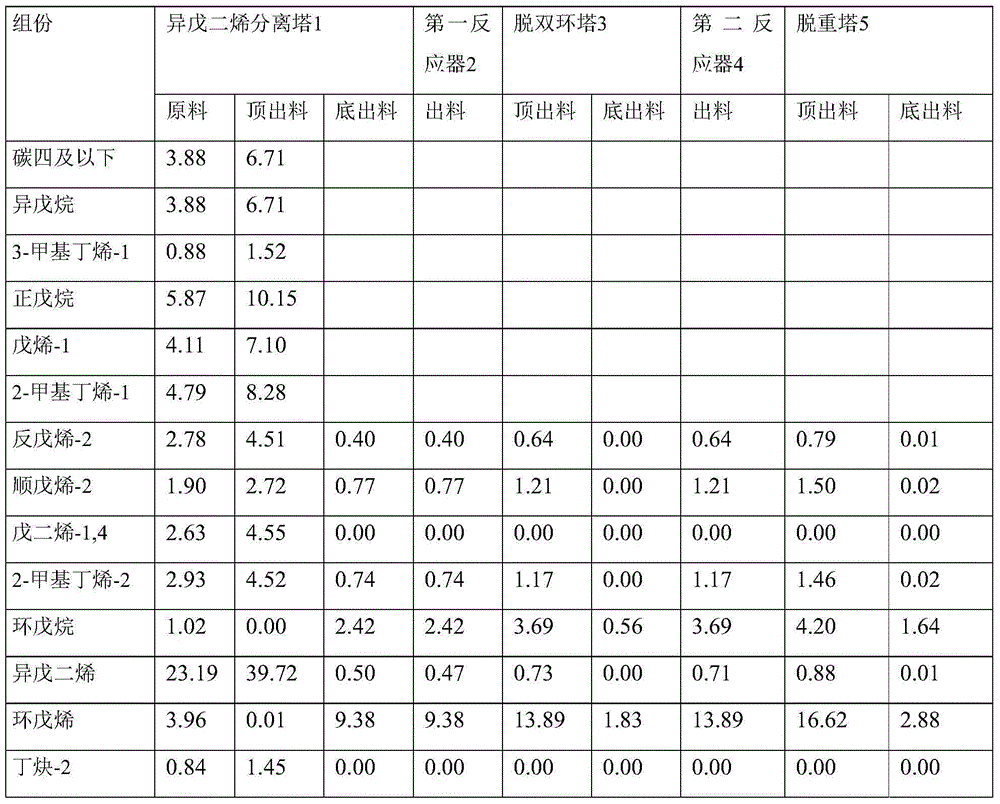

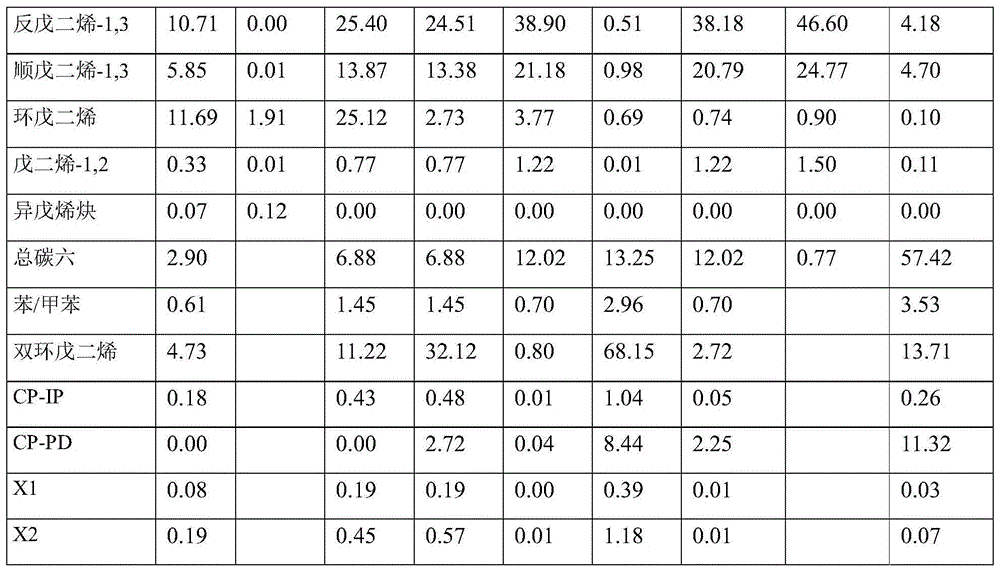

[0059] according to figure 1 The technological process, the crude oil cracking C5 fraction enters the 75th plate of the isoprene separation tower 1, and the top of the tower is separated to obtain a stream I rich in isoprene, which also contains monoolefins, alkanes, alkynes and a small amount The cyclopentadiene; the tower still separates the stream II containing heavy components such as cyclopentadiene and piperylene. The feed temperature of isoprene separation tower 1 is 50°C, the number of trays is 160, the temperature of the tower bottom is 84°C, the temperature of the top of the tower is 54°C, the pressure of the top of the tower is 0.13MPa, the pressure of the bottom of the tower is 0.21MPa, and the reflux The ratio is 11.

[0060] Stream II enters the first thermal dimerization reactor 2 to carry out the thermal dimerization reaction. The volume of the reactor is 40 cubic meters (the raw material petroleum cracking C5 fraction is calculated at 15,000 kg / hour, the same...

Embodiment 2-4

[0089] according to figure 1 The technological process of separating piperylene from raw petroleum cracking C5 fraction, the difference is that the separation conditions of each tower and the operating conditions of the reactor are shown in Table 3. The recovery rates of piperylene are 90.23%, 96.79 and 96.25%, respectively, and the total heat of the bottom of the double-cycling tower 3 and the weight-removing tower 5 are respectively 96.8, 106.5 and 108.1kW / ton of raw material oil. The total cooling capacities at the top of the heavy tower 5 are respectively 109.2, 110.0 and 111.9 kW / ton of feedstock oil, and the composition and other product properties of the raw petroleum cracking fraction are shown in Table 4 (Example 2) and Table 5 (Example 3) And shown in table 6 (embodiment 4).

[0090] table 3

[0091]

[0092]

[0093] Table 4

[0094]

[0095] table 5

[0096]

[0097] Table 6

[0098]

[0099] As can be seen from the results of the above Examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com