Liquid crystal compound and liquid crystal medium comprising compound

A technology of liquid crystal compound and liquid crystal medium, applied in the direction of liquid crystal materials, organic chemistry, chemical instruments and methods, etc., can solve the problems that cannot meet the development needs of mixed liquid crystals, and the types of VA monomer liquid crystals are few

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0106] R 1 stands for C 1 -C 5 straight chain alkyl, C 1 -C 5 straight-chain alkoxy or C 2 -C 5 straight-chain alkenyl, C 2 -C 5 straight-chain alkenyloxy

[0107] "Conventional work-up" means that, if necessary, water is added, the mixture is extracted with dichloromethane, diethyl ether, methyl tert-butyl ether or toluene, the phases are separated, the organic phase is dried and evaporated, and the product is then distilled under reduced pressure or crystallized and / or Or chromatographic purification.

Embodiment 1

[0109]

[0110] Step 1.1

[0111]

[0112] Add 0.9mol chloromethyl ether triphenylphosphonium salt and 1L tetrahydrofuran to a 2L three-necked flask, stir and cool down to 0°C under nitrogen protection, add 1mol potassium tert-butoxide in batches, control the temperature at 0-10°C, and the reaction solution turns reddish brown. After adding potassium tert-butoxide, stir and react for 2 hours, add dropwise 0.8mol cyclopentanone in 100ml tetrahydrofuran solution, control the temperature below 10°C, stir and react for 3 hours after dropping, hydrolyze, separate liquid, extract the aqueous solution twice with 500ml toluene, and combine , wash with water until neutral. Evaporate the solvent to dryness, and distill at atmospheric pressure to obtain the product 0.67mol, GC: 95% yield 83.8%.

[0113] Step 1.2

[0114]

[0115] Add 0.67mol to 1L three-necked bottle 500mL tetrahydrofuran was cooled to 0°C, 200ml concentrated hydrochloric acid and 100ml aqueous solution wer...

Embodiment 2

[0129]

[0130] Step 2.1

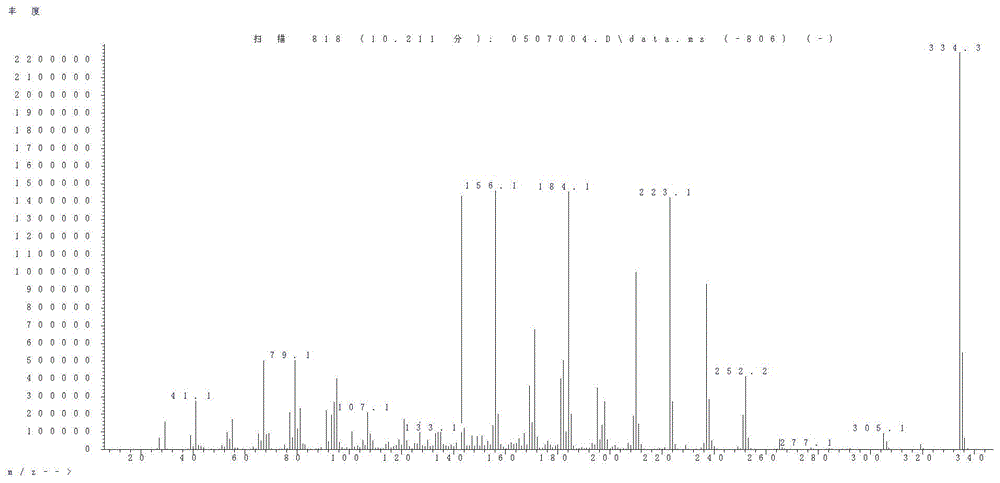

[0131] Add 0.1mol to 1L three-necked bottle 500mLTHF, under the protection of nitrogen, cool down to 0°C, add 0.12mol potassium tert-butoxide in batches, keep T 200ml of THF solution, keep T figure 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com