Special material for automobile bumper and manufacturing method of automobile bumper

A technology for automobile bumpers and special materials, which is applied to bumpers and other directions, can solve the problems of heavy bumpers and poor impact absorption ability, and achieve the effects of high rigidity, reduced energy consumption and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

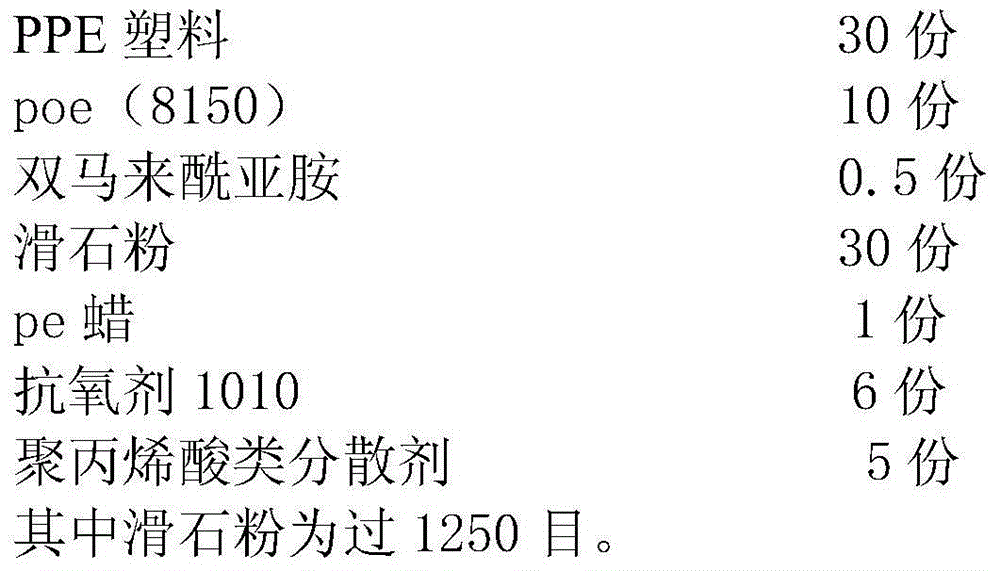

specific Embodiment 2

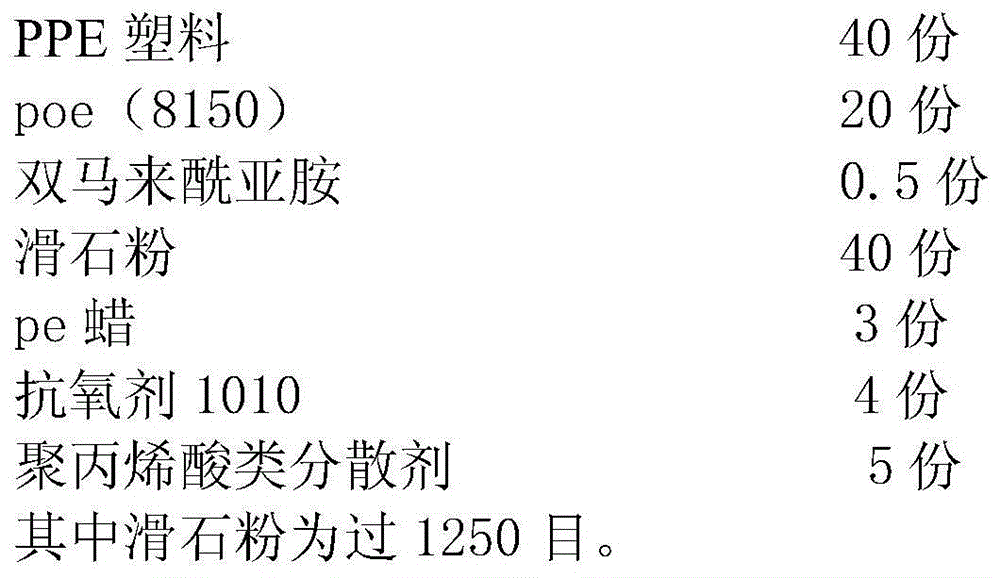

[0024] The technical solution of the present invention is: a special material for automobile bumper, comprising, in parts by mass, consisting of the following components:

[0025]

[0026] Using the above-mentioned materials, the molding method for making an automobile bumper specifically includes the following steps:

[0027] 1) Take out an appropriate proportion of the above raw materials, put them into a pulverizer, stir for 20 minutes, and fully pulverize;

[0028] 2) Put the pulverized material in step 1) into the box, and stir until evenly mixed while adding water;

[0029] 3) Put the uniformly mixed material into the drying box, dry for 30 minutes, remove the moisture, and get the bad material;

[0030] 4) Put the bad material into the barrel of the injection molding machine, and use the heating barrel to melt the PPE plastic in the injection molding machine;

[0031] 5) Take out the melted raw material and push it into the mold, and wait for molding to cool for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com