Heat-resistant cast austenitic stainless steel with excellent high-temperature comprehensive properties

A technology of austenitic stainless steel with comprehensive performance, which is applied in the field of automobile engine exhaust system components and heat-resistant cast austenitic stainless steel, which can solve the problems of high production cost and unsuitability for use in automobile engines, and achieve low production cost and improved Effects of combustion efficiency and exhaust gas purification ability, high temperature resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

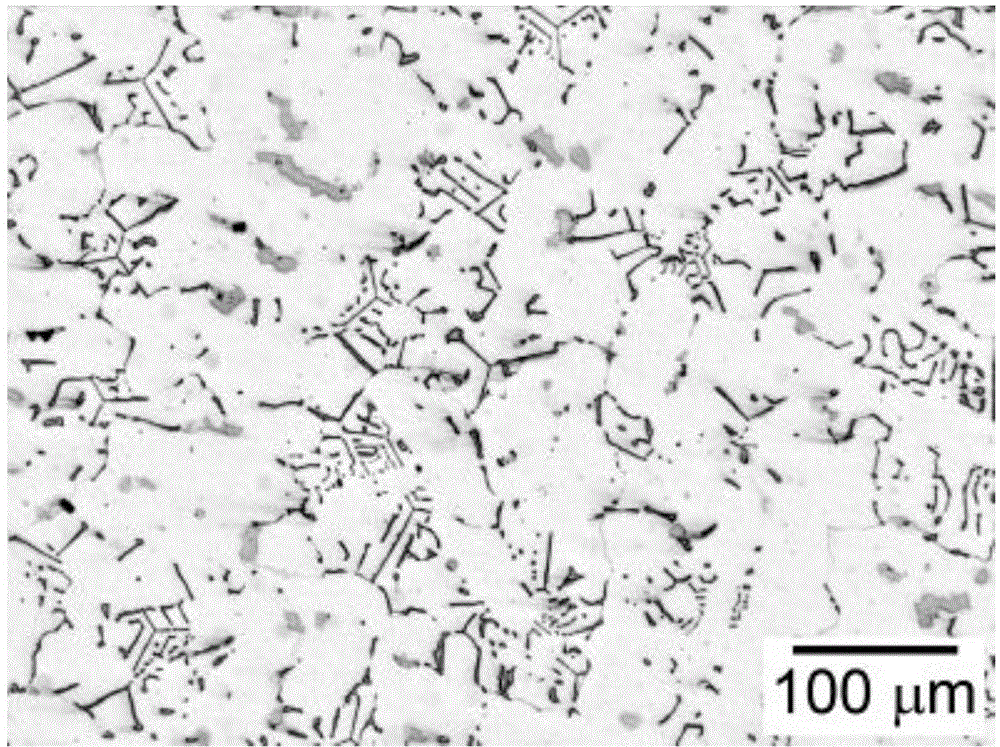

[0067] Examples 5 to 7 are cast steels containing N, W and no Mo, wherein the metallographic microstructure of Example 5 is as follows image 3 shown. The high-temperature creep life of Examples 5-7 at 1000°C and 50 MPa is significantly higher than that of the commercial alloy CF8C-Plus, and its room temperature, high-temperature and low-cycle fatigue life and high-temperature oxidation increment meet the service conditions of the exhaust system.

[0068] Examples 8-10 are cast steels containing N, Mo and no W. Their high-temperature creep life at 1000°C and 50 MPa is significantly higher than that of the commercial alloy CF8C-Plus, and their low-cycle fatigue life at room temperature satisfies the exhaust System service conditions.

[0069] The chemical composition (mass percentage) of table 1 embodiment

[0070] serial number Fe Cr Ni Nb C Si mn N W Mo Example 1 Bal. 20.35 9.86 2.08 0.43 0.60 1.01 0.29 - - Example 2 Bal. 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com