Hot-rolled high-strength low-nickel-copper ratio thick gauge weathering steel and production method thereof

A production method and a nickel-copper ratio technology are applied to hot-rolled high-strength, low-nickel-copper ratio-thick weathering steel and its production field, which can solve the problems of low strength level, reduced economic benefits, and adverse effects on the formability of steel. Thickness specification, excellent effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

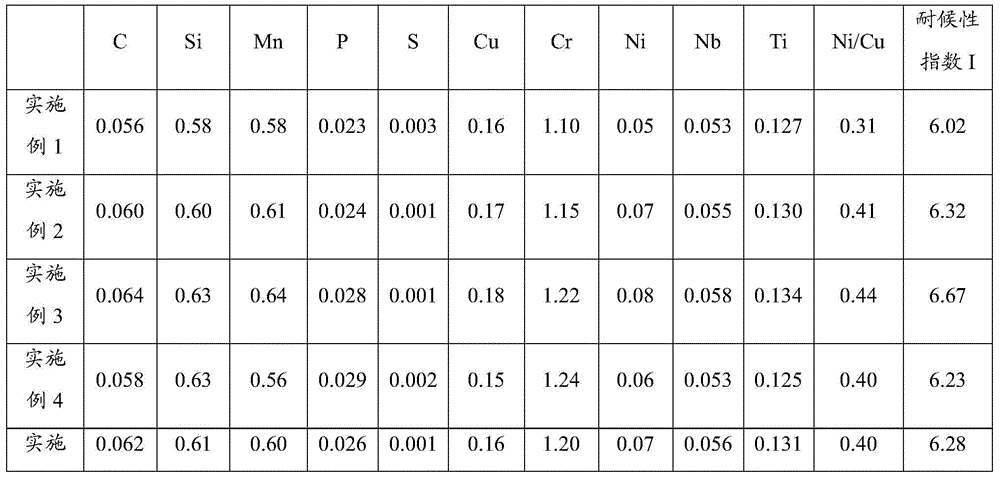

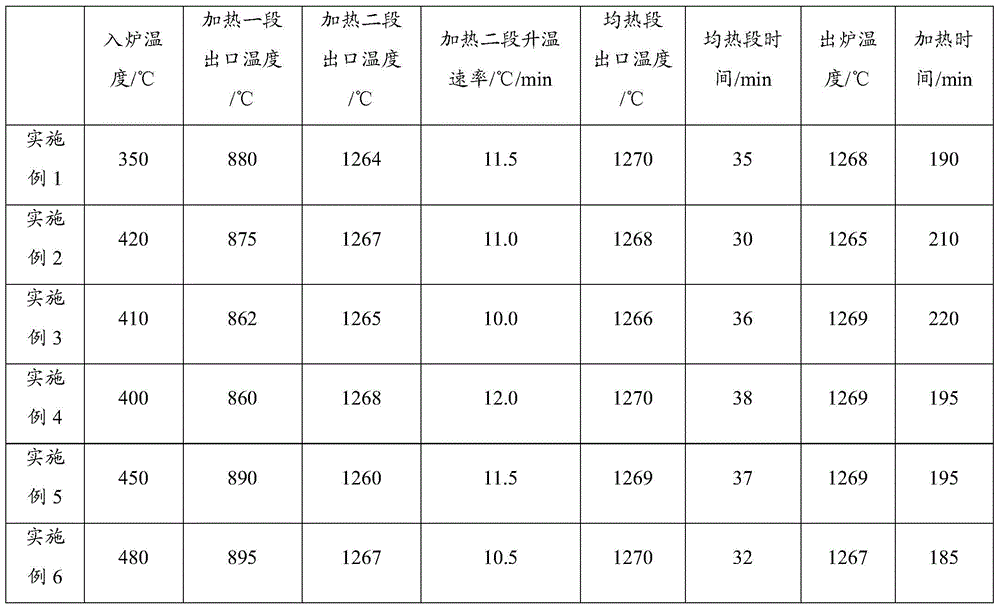

[0017] The embodiment of the present invention provides a hot-rolled high-strength low-nickel-copper ratio thick gauge weathering steel, the mass percentage of its chemical composition is:

[0018] C: 0.055-0.065%; Si: 0.56-0.64%; Mn: 0.55-0.65%; P: 0.022-0.030%; S≤0.005%; Cu: 0.15-0.19%; Cr: 1.05-1.25%; -0.09%; Nb: 0.052-0.058%; Ti: 0.125-0.135%, the rest is Fe and unavoidable impurities. Wherein, the nickel-copper ratio is less than or equal to 0.45.

[0019] Among them, C element is one of the most effective strengthening elements in steel, and it is also the cheapest chemical element, but C can significantly reduce the plasticity and toughness of steel, and the higher the carbon content, the worse the welding performance. Therefore, this In the embodiment of the invention, the C content range is controlled at 0.055% to 0.065%.

[0020] Si element has a strong solid solution strengthening effect, which can significantly increase the tensile strength of steel, and slightly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com