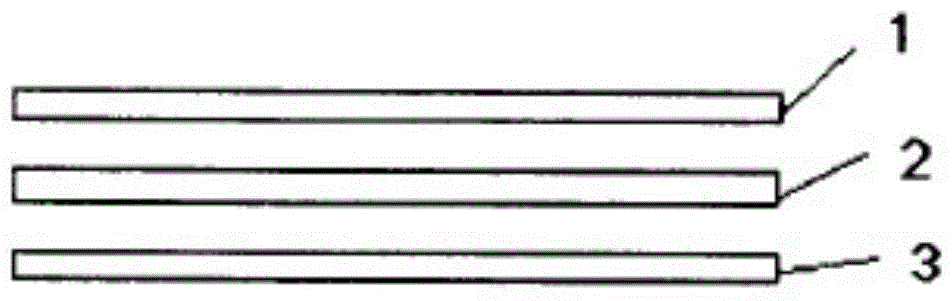

Layered composite aramid fiber paper and preparation method thereof

A technology of aramid fiber and aramid chopped fiber, which is applied in the field of papermaking and can solve problems such as foaming, high density, and poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] [Example 1] Proportional configuration and preparation method of layered composite aramid fiber paper of the present invention

[0034] The scale configuration looks like this:

[0035] Top and bottom layers:

[0036] 1313 aramid chopped fiber (6mm) 75 parts by weight

[0037] 1313 aramid precipitated fiber 25 parts by weight

[0038] Core layer:

[0039] 1313 aramid chopped fiber (6mm) 25 parts by weight

[0040] 1313 aramid precipitated fiber 75 parts by weight

[0041] Preparation:

[0042] First, aramid chopped aramid fiber with a length of 6 mm and a fineness of 1.5 denier, that is, polym-phenylene isophthalamide fiber, is dispersed in water to form a slurry, and the mass concentration is 0.3%. Aramid chopped fiber slurry; then the aramid fibrids are dispersed and loosened in water, disc milled until the degree of percussion is 500SR, and aramid fibrous slurry with a mass concentration of 1% is made; then the above core layer Proportion Mix 1313 aramid chopp...

Embodiment 2

[0049] [Example 2] Proportional configuration and preparation method of layered composite aramid paper of the present invention

[0050] Top and bottom layers:

[0051] 1414 aramid chopped fiber (6mm) 75 parts by weight

[0052] 1313 aramid precipitated fiber 25 parts by weight

[0053] Core layer:

[0054] 1414 aramid chopped fiber (6mm) 25 parts by weight

[0055] 1313 aramid precipitated fiber 75 parts by weight

[0056] In this embodiment, aramid 1414 chopped fibers are used instead of 1313 chopped fibers, and the physical properties of the formed paper are as follows:

[0057] Quantitative: 41g / ㎡

[0058] Thickness: 0.050mm

[0059] Tensile strength 45N / cm

[0060] Dielectric strength 20KV / mm

Embodiment 3

[0061] [Example 3] Proportional configuration and preparation method of layered composite aramid paper of the present invention

[0062] Top and bottom layers:

[0063] 1313 aramid chopped fiber (6mm) 80 parts by weight

[0064] 1313 aramid precipitated fiber 20 parts by weight

[0065] Core layer:

[0066] 1313 aramid chopped fiber (6mm) 20 parts by weight

[0067] 1313 aramid fibrid fiber 80 parts by weight

[0068] Preparation:

[0069] Firstly, the length of aramid chopped fiber is 6mm, and the aramid fiber chopped fiber with a fineness of 2.0 denier, that is, polym-phenylene isophthalamide fiber, is dispersed in water to form a slurry, and the mass concentration is 0.5%. Aramid chopped fiber slurry; then disperse the aramid precipitated fiber in water, disc grind until the degree of percussion is 550SR, and make an aramid precipitated fiber slurry with a mass concentration of 1.5%; then use the above core layer ratio Mix 1313 aramid chopped fibers and 1313 aramid fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com