Plunger pump valve plate with local micro unit structures

A valve plate, unit body technology, applied in pump control, pump components, variable capacity pump components, etc., can solve problems such as failure to solve eccentric wear, narrow application area, increased cost, etc., to achieve a wide range of use, eccentric load The effect of less wear and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

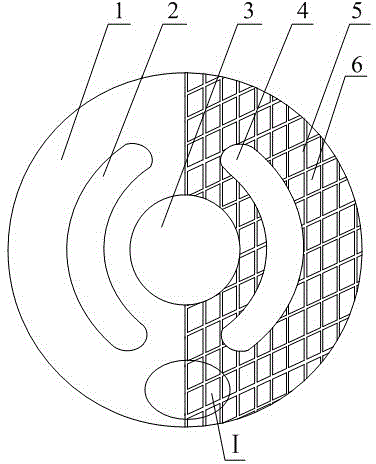

[0022] A plunger pump with a local micro unit structure.like figure 1 It is shown that the stream disk is equipped with a central hole 3, the center -to -hole 3 is equipped with oil windows 2, the other side of the center Tongkou 3 is equipped with oil -absorbing window 4, oil windows 2 and oil absorption window 4 are all are all are all"C" shaped pores, oil windows 2 and oil -absorbing window 4 The diameter lines of the stream disk are symmetrically distributed along the stream disk. A diameter lines are divided into two semi -circular dial surfaces of equal area.

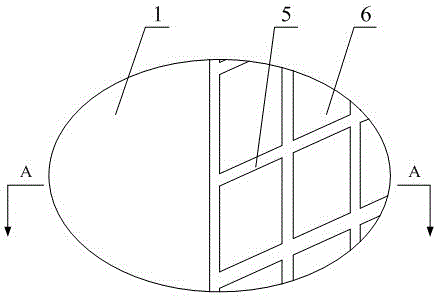

[0023] The semi -circular stream disk surface where the oil windows 2 are located is the oil stream disk surface 1, and the other semi -circular stream disk of the oil absorption window 4 is 5.like figure 1 and figure 2 Show, there are density distribution such as micro unit body structure 6 and microfinance structure 6 in the oil absorption dishes 5.

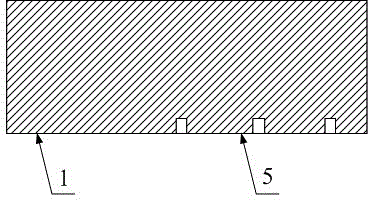

[0024] The structure of the micro unit body 6 is a miniature conv...

Embodiment 2

[0026] A plunger pump with a local micro unit structure.Except for the following structure, the rest are the same as 1.

[0027] There are density distribution such as micro unit body structure 6 and microfinance structure 6 in the oil absorption dishes 5.

[0028] The structure of the micro unit body 6 is a miniature convex, and the upper surface shape of the micro conveye is a triangle, round, polygon, and oval.The area of the distribution disk is 50 ~ 80%, and the shape distance of the two adjacent micro convectors is 10-60 μm.5-50 μm.

[0029] Compared with the existing technology, this specific implementation method has the following advantages:

[0030] 1. This specific embodiment is only set with a microstrobine structure 6 in any half of the circular distribution disk. It does not require other regulatory devices. The work is safe and reliable, simple structure and low cost.

[0031] 2. This specific implementation method has a microfinance structure 6 in any half of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com