Micro-miniature catalytic burner taking foam metal as catalyst structure substrate

A catalytic burner and foam metal technology, which is applied to gas fuel burners, burners, burners, etc., can solve the problems of large flow resistance, large heat loss of homogeneous combustion, and small effective catalytic area of catalytic burners. The effective catalytic area is small, the stability is improved, and the effect of overcoming the large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

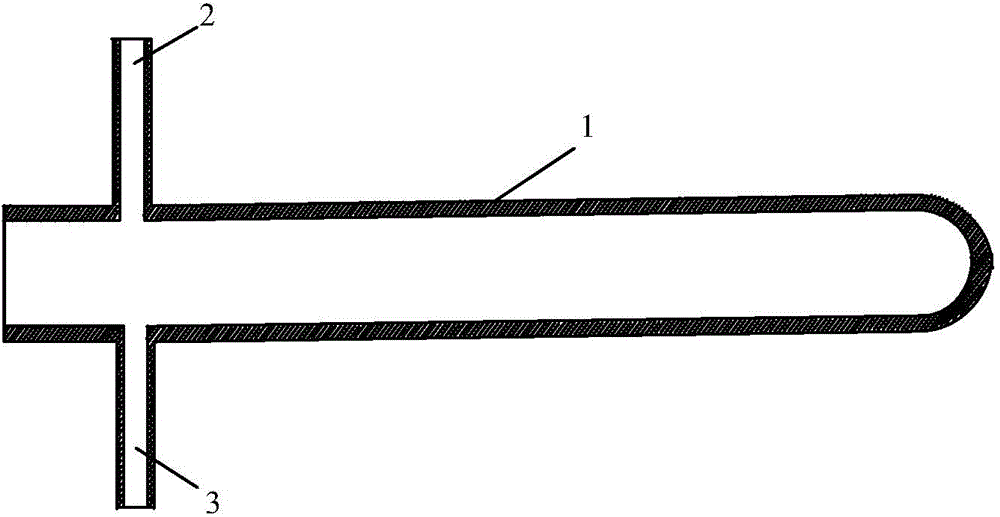

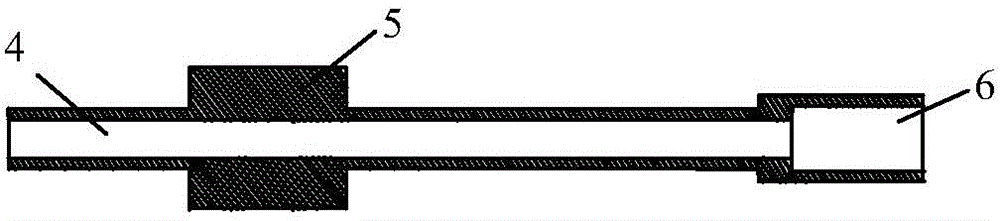

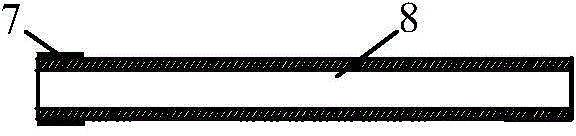

[0023] Such as Figure 4 Shown, a kind of micro catalytic burner that uses metal foam provided by the invention as catalyst carrier comprises following structure: reactant inlet 9, tail gas outlet 2 and 3, reactant inlet channel 4, catalytic combustion reaction chamber inlet 10, catalytic combustion Reaction chamber 6 , integral catalyst 14 , product channel inlet 11 , product channel 8 , heat recovery channel inlet 12 , and heat recovery channel 13 . When working, the entire periphery of the miniature catalytic burner is covered with thermoelectric materials to achieve the effect of converting thermal energy into electrical energy. The working medium can be a certain hydrocarbon fuel such as hydrogen, propane, n-butane, methane, etc., or a mixed hydrocarbon fuel. When the micro-catalytic burner starts to work, the premixed fuel can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com