Electrochemical analysis in-situ cell for X-ray diffraction and testing method

A technology of electrochemical analysis and in-situ cell, which is applied in the direction of material analysis, measuring electricity, and measuring devices using radiation diffraction. It can solve the problems of crystal structure changes and difficulties in real-time detection, and achieve low cost, good airtightness, and enhanced signal. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] Specific embodiment 1: study LiFePO 4 Phase transition of battery materials during charge and discharge

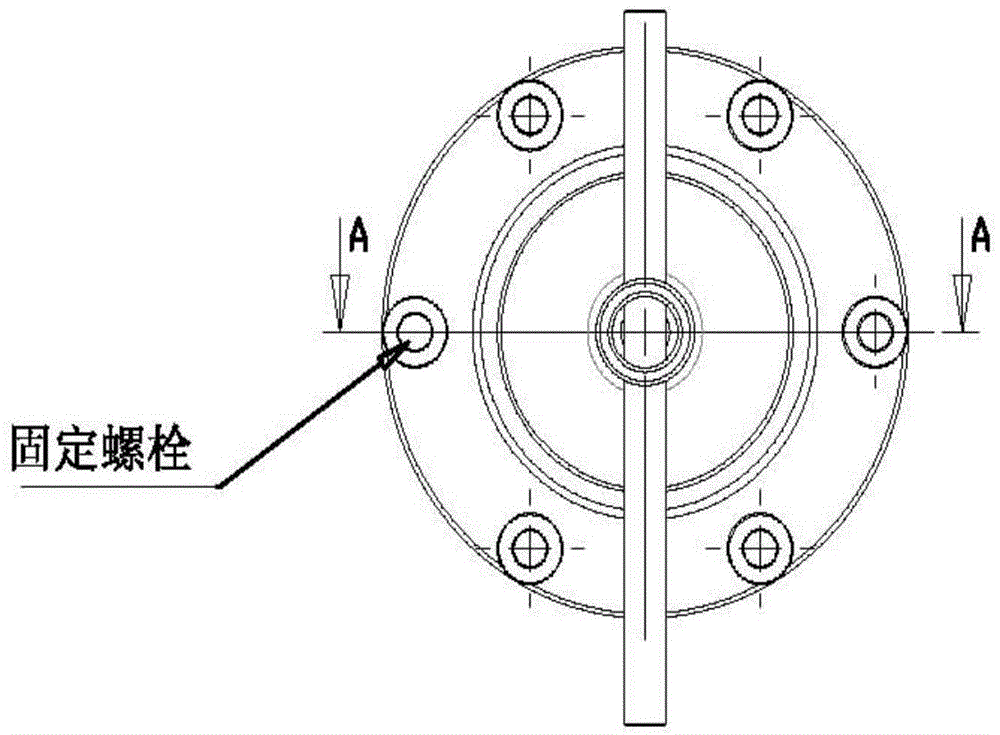

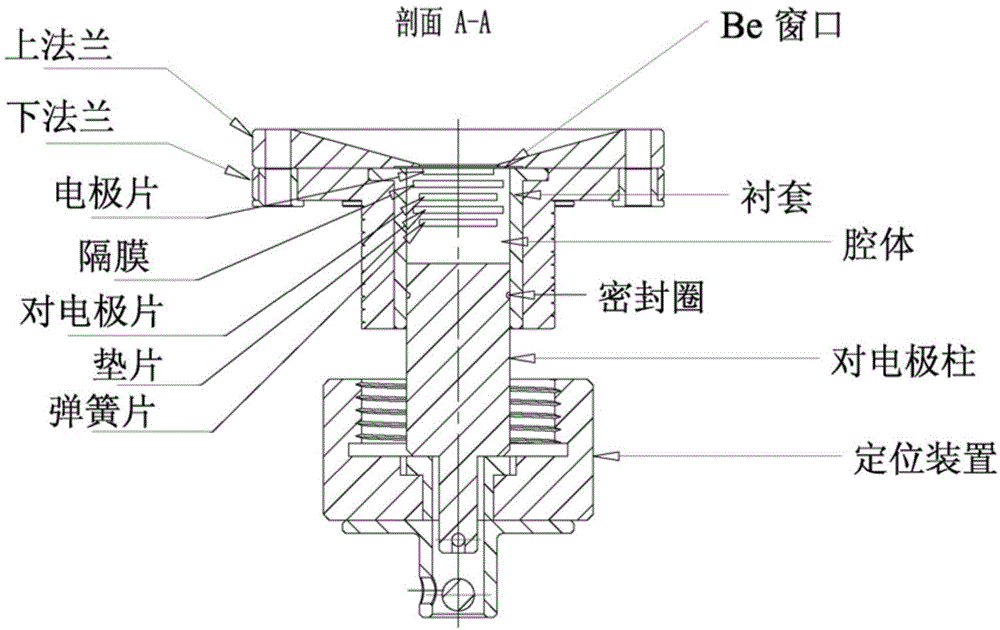

[0031] Assembling the battery steps: first fix the Be plate, turn the in-situ cell upside down, and put LiFePO on the beryllium window 4 Cathode pole piece, diaphragm, counter electrode piece, electrolyte solution, counter electrode column, and insulated tweezers are used to prevent short circuit of the in-situ cell. During the assembly process, pay attention to the subassembly sequence.

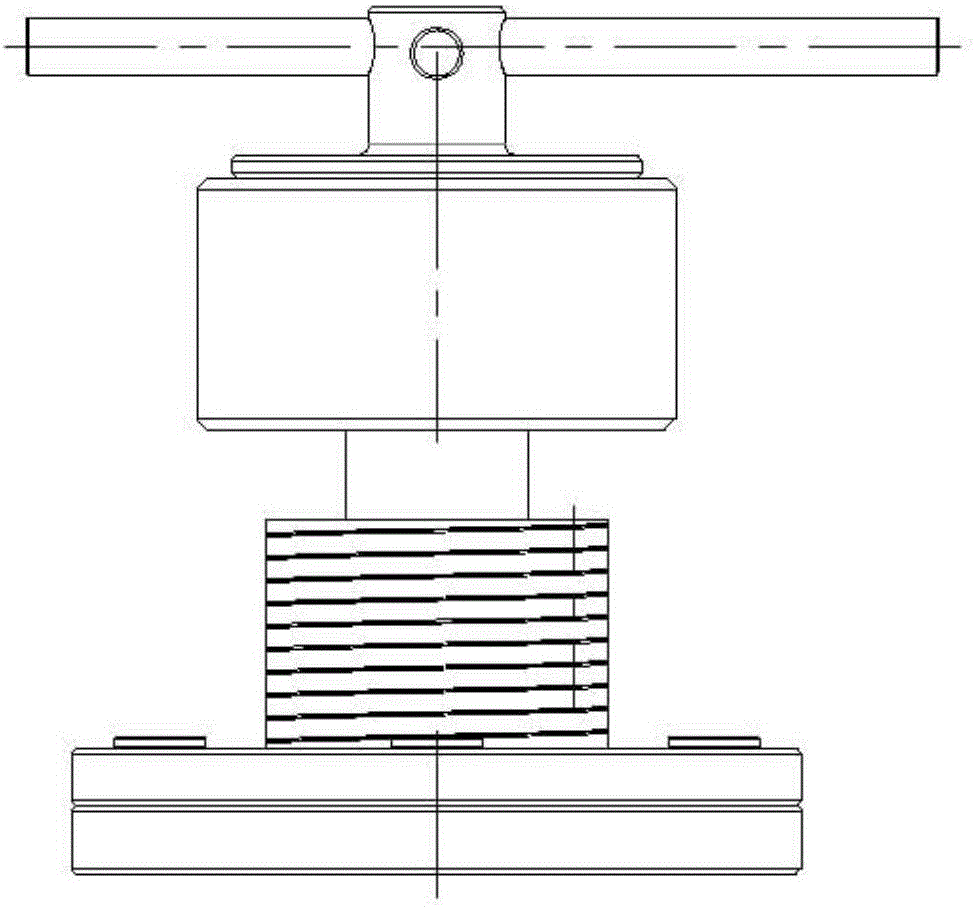

[0032] Place the in-situ cell on the sample stage of the X-ray powder diffractometer and connect the electrodes and counter electrode leads. The start-up conditions of the in-situ cell: charge and discharge according to the corresponding rate respectively, and collect points after discharging, and the battery is static for 7 minutes during the point collection process. X-ray powder diffractometer test conditions: Cu target, voltage 40Kv, current 40mA, scanning range: 28-42°, sc...

specific Embodiment 2

[0034] Specific Example 2: Studying the phase transition of three-element battery materials in the charging and discharging process

[0035] The start-up conditions of the in-situ cell: charge and discharge at 0.2C, charge and discharge to the corresponding voltage, stand still for 17 minutes, and test. X-ray powder diffractometer test conditions: Cu target, voltage 40Kv, current 40mA, scanning range: 35-70°, scanning rate: 2° / min, using automatic sampling programming software, sampling points every 45 minutes, sampling time It is 17min.

[0036] The data tested above is to use the in situ cell test to study the phase transition of NCM battery materials during the charging and discharging process. The test results are as follows: Figure 4As shown, the results show that NCM can realize the reversible transformation of the crystal phase. During the charging process, the H1 phase gradually transforms into the H2 phase, and when the voltage is 4.5V, the H3 phase begins to appear...

specific Embodiment 3

[0037] Specific embodiment 3: Study the phase transition of high voltage LCO battery material charge and discharge process

[0038] The start-up conditions of the in-situ cell: charge and discharge at 0.2C, charge to the corresponding voltage and rest for 17 minutes. X-ray powder diffractometer test conditions: Cu target, voltage 40Kv, current 40mA, scanning range: 35-70°, scanning rate: 2° / min, using automatic sampling programming software, sampling points every 45 minutes, sampling time It is 17min.

[0039] The data tested above is to use the in-situ cell test to study the phase transition of LCO battery materials during high-voltage charging and discharging. The test results are as follows: Figure 5 As shown, the results show that when the voltage is higher than 4.5V, the LCO material will appear O1a and O1 crystal phases during the charging process, and the appearance of these crystal phases is not conducive to the layered structure of the material. The phase has compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com