Vacuum acquisition device for EUV irradiation material test system and corresponding test method

A material testing, extreme ultraviolet technology, applied in the field of EUV lithography, can solve the problem that the quadrupole mass spectrometer cannot be used directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

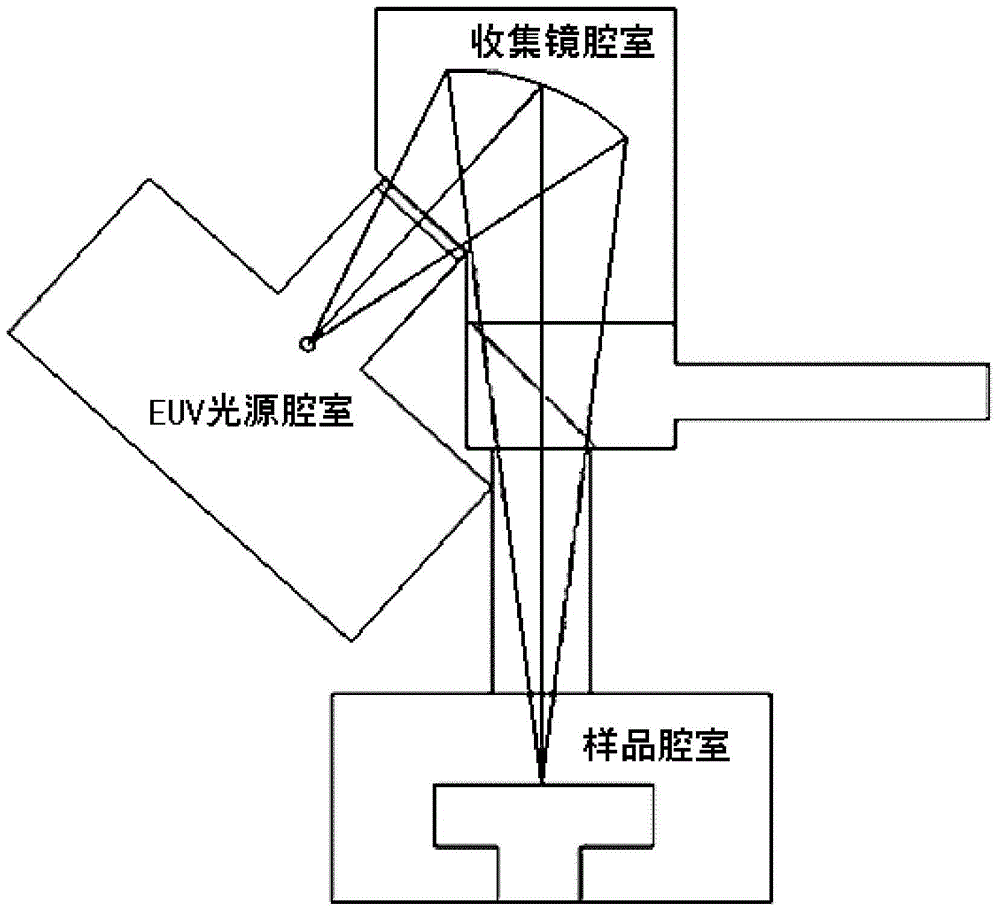

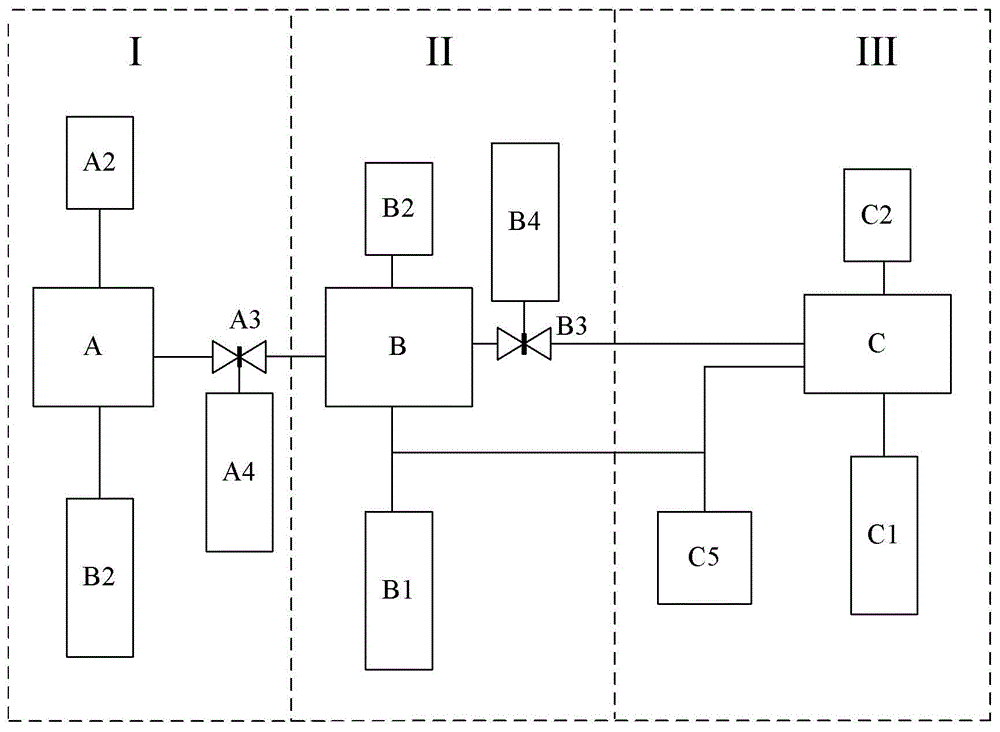

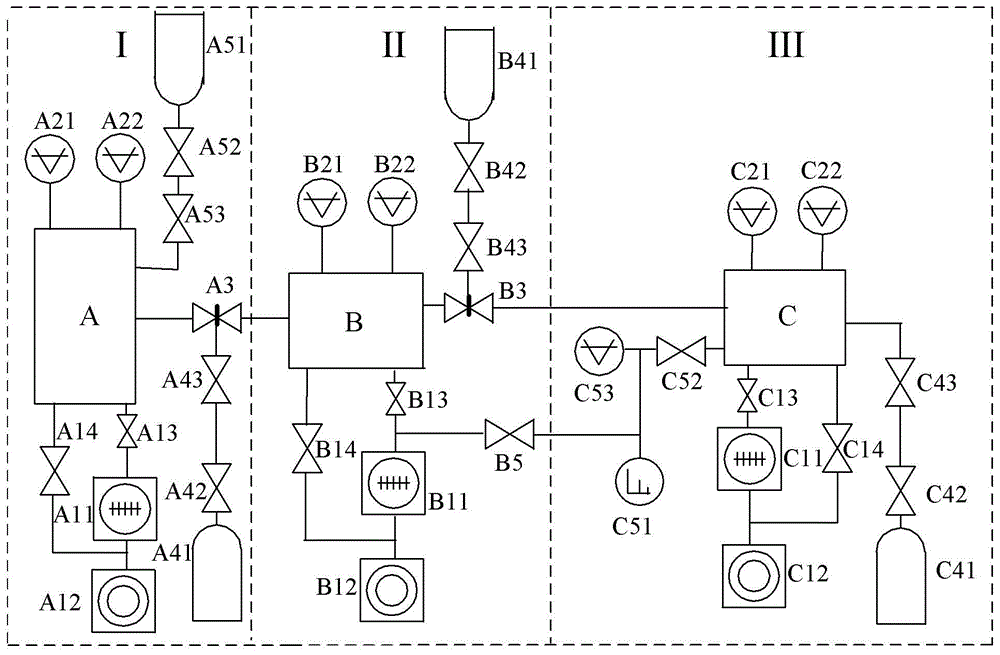

[0025] figure 2 It is a structural schematic diagram of a vacuum obtaining device suitable for EUV irradiated material testing system of the present invention. Such as figure 2 As shown, the EUV irradiated material testing system includes EUV light source chamber A, collector mirror chamber B and sample chamber C. The vacuum obtaining device of the present invention can be divided into an EUV light source chamber vacuum system (part I in the figure), a collector mirror chamber vacuum system (part II in the figure), and a sample chamber vacuum system (part III in the figure).

[0026] The vacuum obtaining device of the present invention includes a vacuum pump unit and a vacuum gauge unit respectively connected to the EUV light source chamber A, the collecting mirror chamber B and the sample chamber C. The vacuum pump unit is used to evacuate each chamber, and the vacuum gauge unit is used to measure the vacuum degree of the chamber. Such as figure 2 As shown, the vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com