Optical switch array module and chamfered optical fiber array packaging method

A technology of optical switch array and optical fiber array, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of high loss, unfavorable high-speed signal transmission, unsuitable for high-integration packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

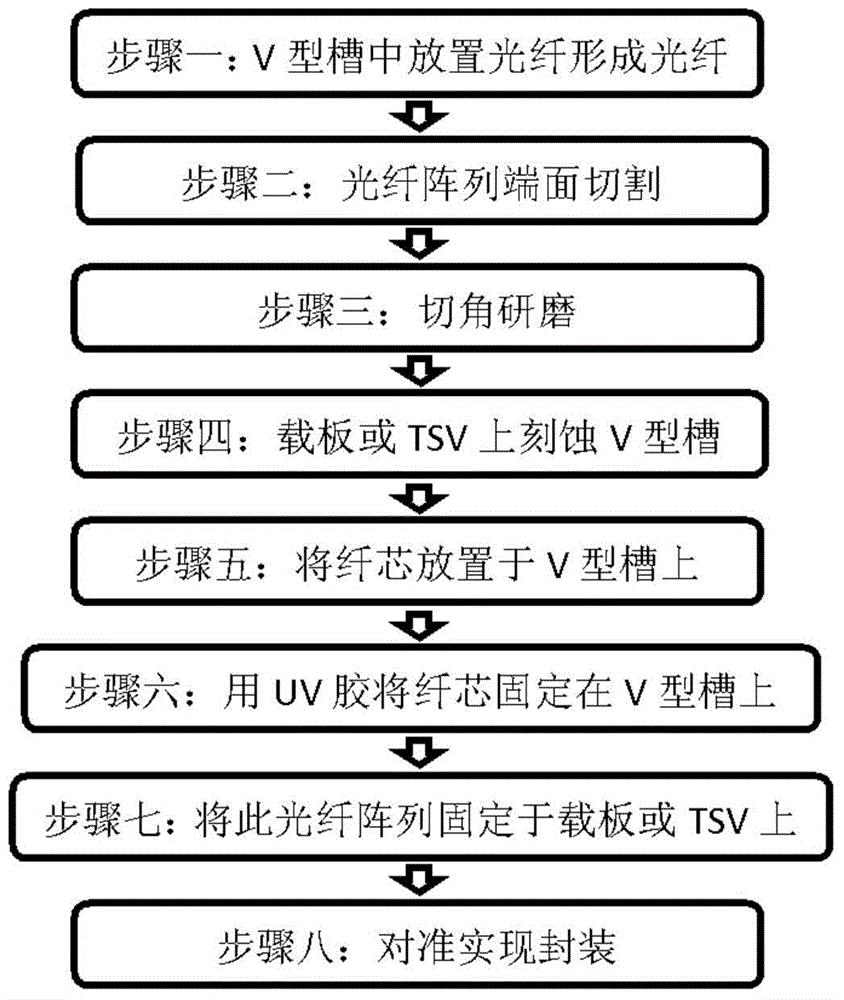

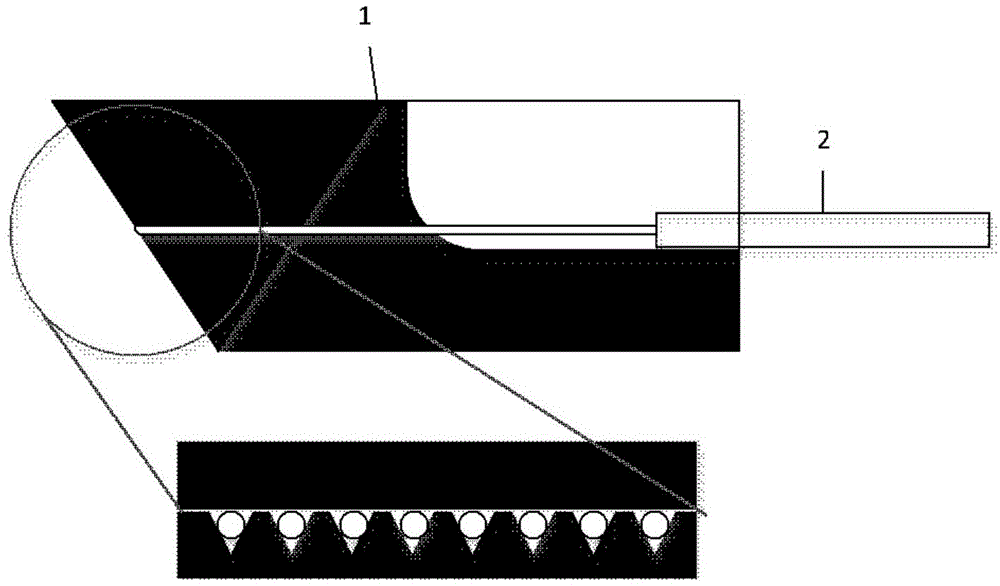

[0018] see figure 1 and figure 2 As shown, the present invention provides a packaging method for an optical switch array module and a cut-angle optical fiber array, including the following steps:

[0019] Step 1: Place the optical fiber 2 in the V-groove fixture 1 to form an optical fiber array, and the angle of the V-groove on the V-groove fixture 1 is 120-30 degrees;

[0020] Step 2: The end face of the optical fiber array formed in the V-groove fixture 1 is cut once to form a consistent cut angle, and the angle of the cut angle formed by the cutting is 45 degrees;

[0021] Step 3: Grinding the chamfer formed by one-time cutting;

[0022] Step 4: Etching a V-shaped groove on a carrier or the TSV on the carrier, the material of the carrier is a polymer-based composite material, and the angle of the V-groove on the carrier or the TSV is 120 degrees -30 degrees;

[0023] Step 5: Fix the fiber core of the optical fiber 2 on the carrier plate or the V-groove etched on the TS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com