A kind of spherical cobalt difluoride used for battery cathode material and preparation method thereof

A battery positive electrode and cobalt difluoride technology, which is applied in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve problems such as hindering applications and poor conductivity, reduce safety hazards, and increase specific capacitance , the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

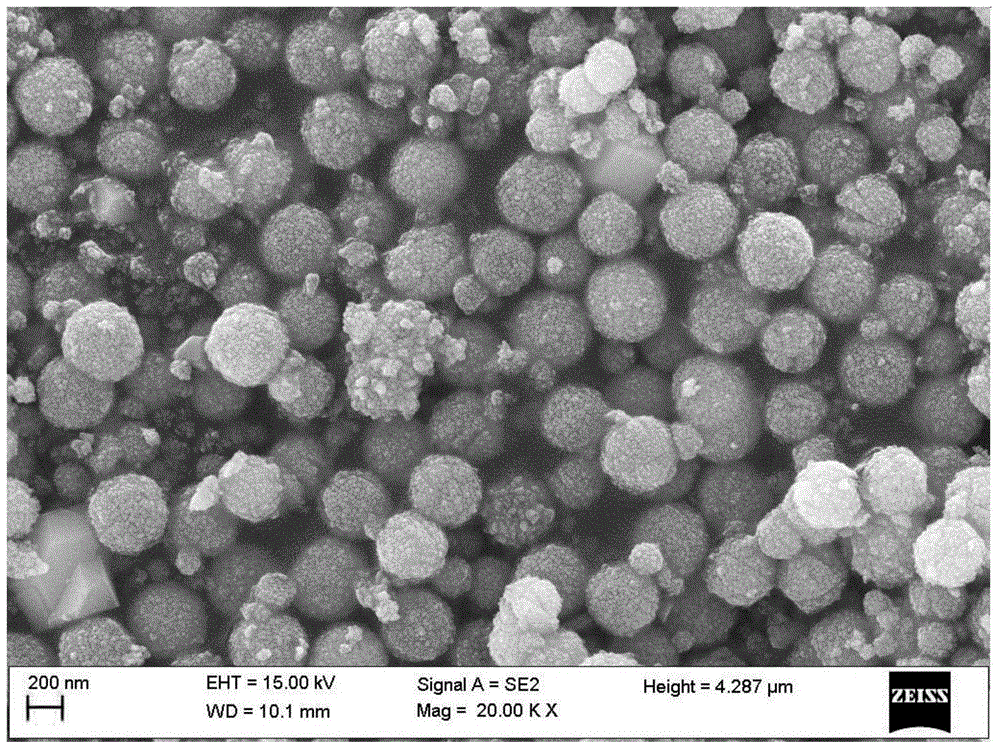

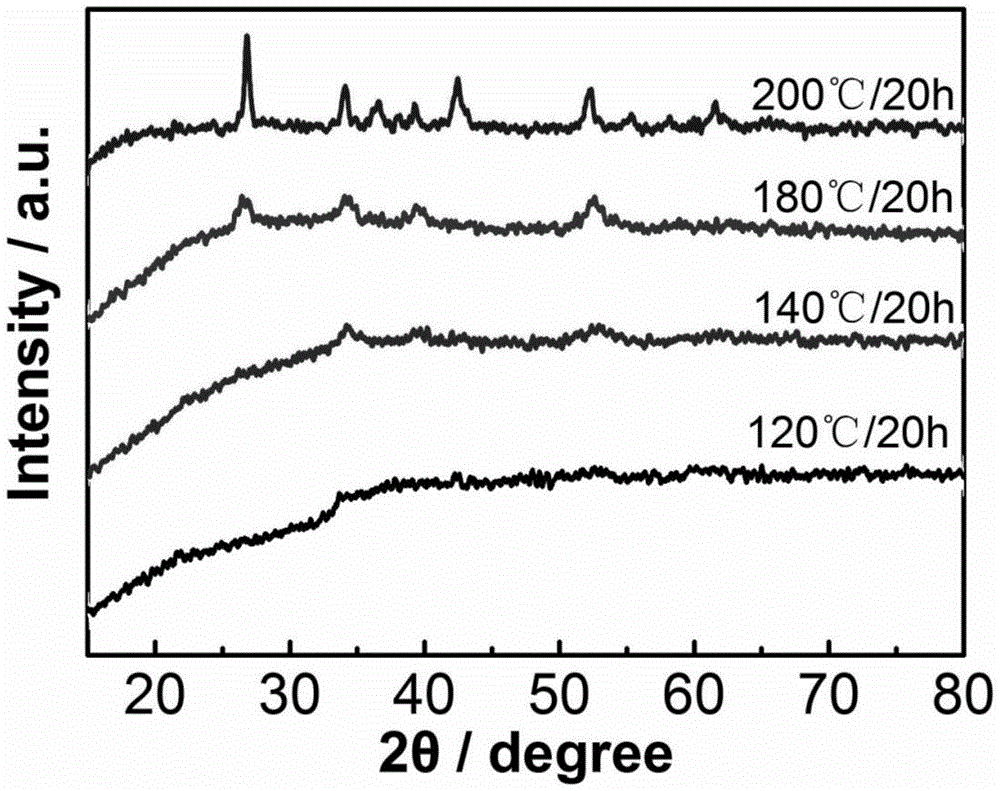

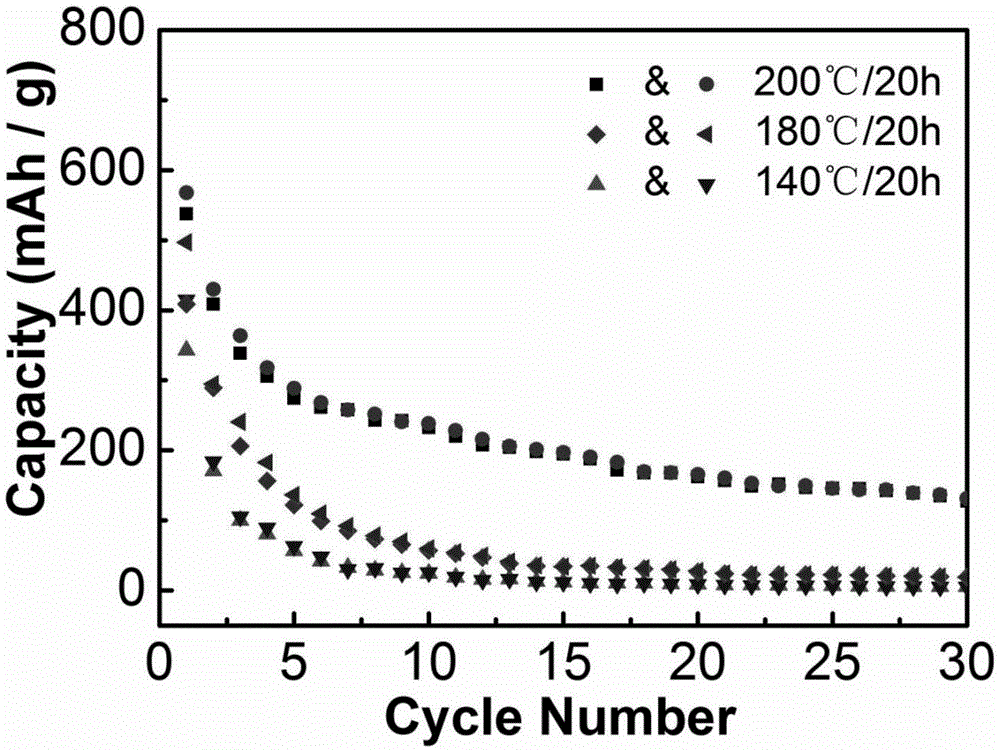

[0023] Weigh 0.29g of cobalt nitrate hexahydrate, 0.12g of ammonium fluoride, and 0.3g of urea, the molar ratio of cobalt nitrate hexahydrate, ammonium fluoride and urea is 1:3:5, stir and mix in 50mL ethylene glycol solution, The concentration of cobalt nitrate hexahydrate dissolved in ethylene glycol was 5.8 mg / mL to obtain a pink homogeneous mixed solution; then, the mixed solution was transferred to a polytetrafluoroethylene-lined reactor and reacted at 200°C for 20 hours; After the reaction is completed, centrifuge to collect the precipitated matter, wash with absolute ethanol and deionized water three times respectively, dry at 50°C for 12 hours in a blast drying oven, and grind to obtain a pink powder sample. The SEM picture of the sample is as follows figure 1 , indicating that the sample is a spherical CoF 2 , is composed of stacked nano-sized particles, with a particle size of 100-500nm.

[0024] Mix the spherical cobalt difluoride powder, conductive carbon black, ...

Embodiment 2

[0026] Take by weighing cobalt nitrate hexahydrate 0.29g, ammonium fluoride 0.12g and urea 0.3g, the mol ratio of hexahydrate cobalt nitrate, ammonium fluoride and urea is 1:3:5, stir and mix in 100mL ethylene glycol solution, six The concentration of cobalt nitrate in water dissolved in ethylene glycol was 2.9mg / mL, and a pink homogeneous mixed solution was obtained; then, the mixed solution was transferred to a polytetrafluoroethylene-lined reactor and reacted at 180°C for 20h; After completion, centrifuge to collect the precipitated matter, wash with absolute ethanol and deionized water three times respectively, dry at 80°C for 6 hours in a blast drying oven, and grind to obtain a pink powder sample. The SEM images of samples with figure 1 The structures shown are similar, indicating that the sample is a spherical CoF 2 , is composed of stacked nano-sized particles, with a particle size of 100-500nm.

[0027] Mix the spherical cobalt difluoride powder, conductive carbon b...

Embodiment 3

[0029] Take by weighing cobalt nitrate hexahydrate 0.29g, ammonium fluoride 0.12g and urea 0.3g, the mol ratio of hexahydrate cobalt nitrate, ammonium fluoride and urea is 1:3:5, stir and mix in 80mL ethylene glycol solution, six The concentration of cobalt nitrate in water dissolved in ethylene glycol was 3.6mg / mL, and a pink homogeneous mixed solution was obtained; then, the mixed solution was transferred to a polytetrafluoroethylene-lined reactor and reacted at 140°C for 20 hours; After completion, centrifuge to collect the precipitated matter, wash with absolute ethanol and deionized water three times respectively, dry at 70°C for 7 hours in a blast drying oven, and grind to obtain a pink powder sample.

[0030] Mix the spherical cobalt difluoride powder, conductive carbon black, and binder (PVDF) obtained above at a ratio of 80:10:10, apply the slurry on the Al foil, and dry it at 70°C. Roll on a roller machine, cut into discs with a diameter of 8mm, put them in a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com