Three-dimensional parallel collagenous fiber-silk bracket as well as preparation method and application thereof

A collagen fiber and silk technology, which is applied in the field of three-dimensional parallel collagen fiber-silk scaffold and its preparation, can solve the problems of far away and achieve the effects of promoting differentiation, good biocompatibility and promoting regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

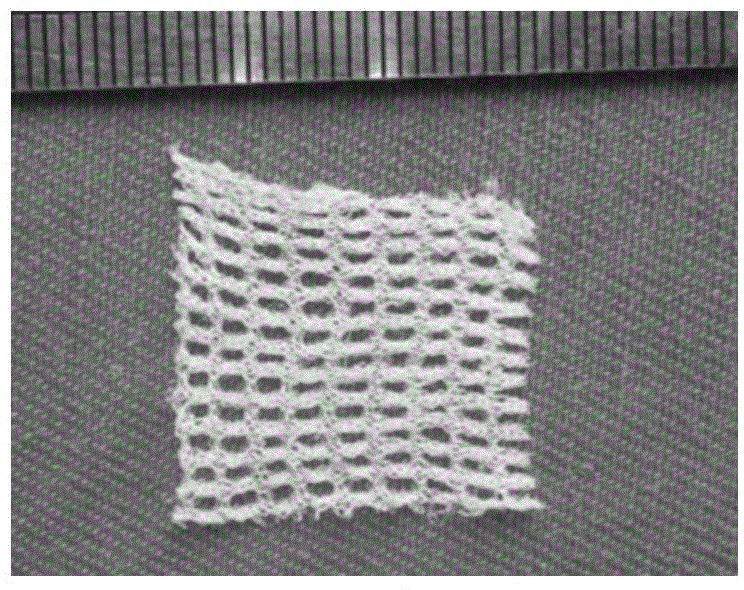

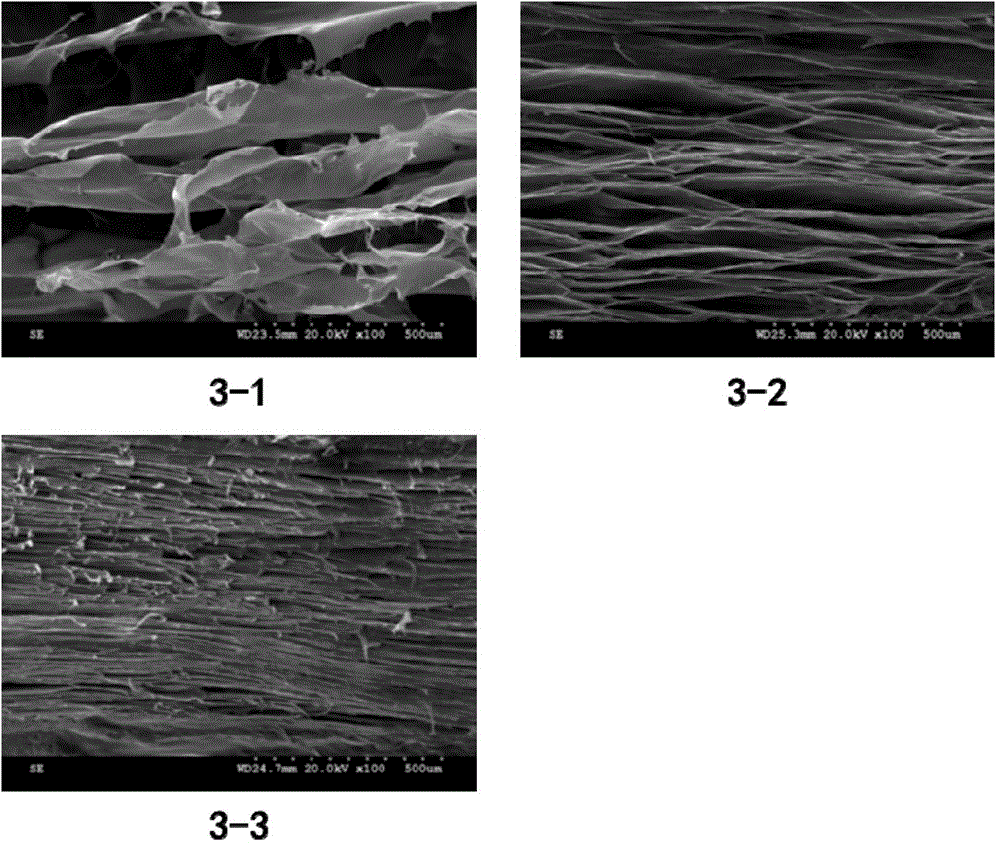

[0041] Set the mesh size to 1mm 2 woven silk with sericin removed, cut into 2*2cm (see figure 1 ). Inject 2mm thick 6mg / ml collagen below the braided silk, and inject 3mm thick 6mg / ml collagen above the braided silk. Adjust the distance between the foam box containing liquid nitrogen and the mold to be 5 cm. After solidification, place it in a vacuum drying machine to dry it, and then perform dry heat crosslinking to obtain a three-dimensional parallel collagen fiber-silk scaffold with a pore diameter of about 200um. Observe its scanning electron microscope picture (see Figure 3-1 ).

Embodiment 2

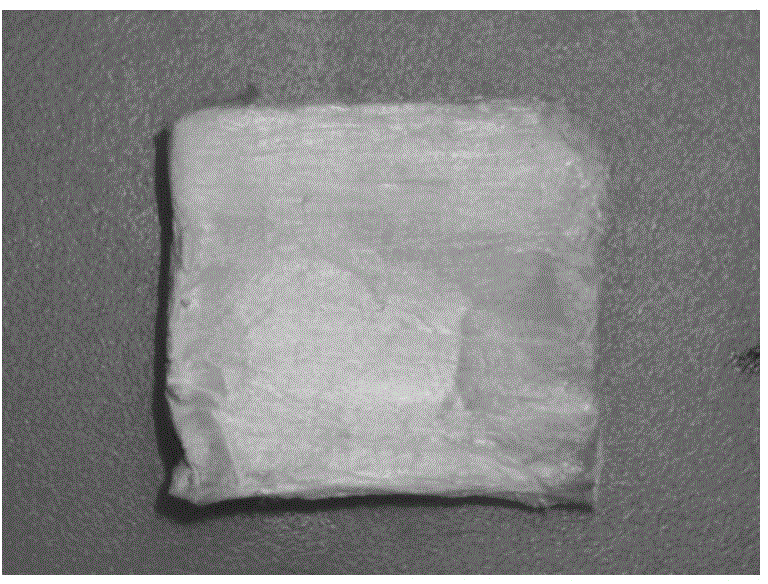

[0043] Set the mesh size to 1mm 2 The woven silk has sericin protein removed and cut into 2*2cm. 2mm thick 10mg / ml collagen was injected below the braided silk, and 3mm thick 10mg / ml collagen was injected above the braided silk. Adjust the distance between the foam box containing liquid nitrogen and the collagen and silk to 5 cm. After solidification, place it in a vacuum dehydrator to dry it, and then perform dry heat crosslinking to obtain a three-dimensional parallel collagen fiber-silk scaffold with a pore diameter of about 80um (see figure 2 ). Observe its scanning electron microscope picture (see Figure 3-2 ).

Embodiment 3

[0045] Set the mesh size to 1mm 2The woven silk has sericin protein removed and cut into 2*2cm. 2mm thick 18mg / ml collagen was injected below the braided silk, and 3mm thick 18mg / ml collagen was injected above the braided silk. Adjust the distance between the foam box containing liquid nitrogen and the collagen and silk to 5 cm. After solidification, place it in a vacuum drying machine to dry it, and then perform dry heat crosslinking to obtain a three-dimensional parallel collagen fiber-silk scaffold with a pore diameter of about 20um. Observe its scanning electron microscope picture (see Figure 3-3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com