A kind of preparation method of boron-containing cross-shaped titanium dioxide photocatalyst

A technology of titanium dioxide and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and hydrogen production. It can solve the problems of weak catalytic hydrogen production performance and complicated methods of photocatalysts. Simple process and low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

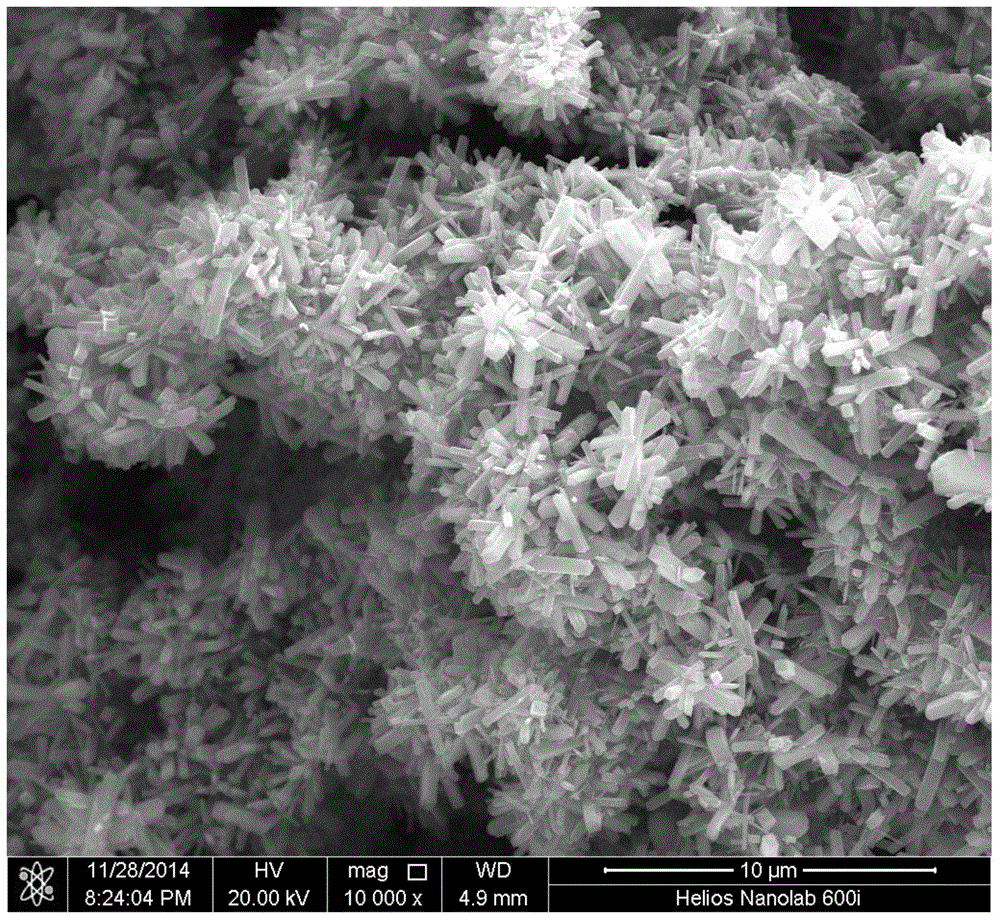

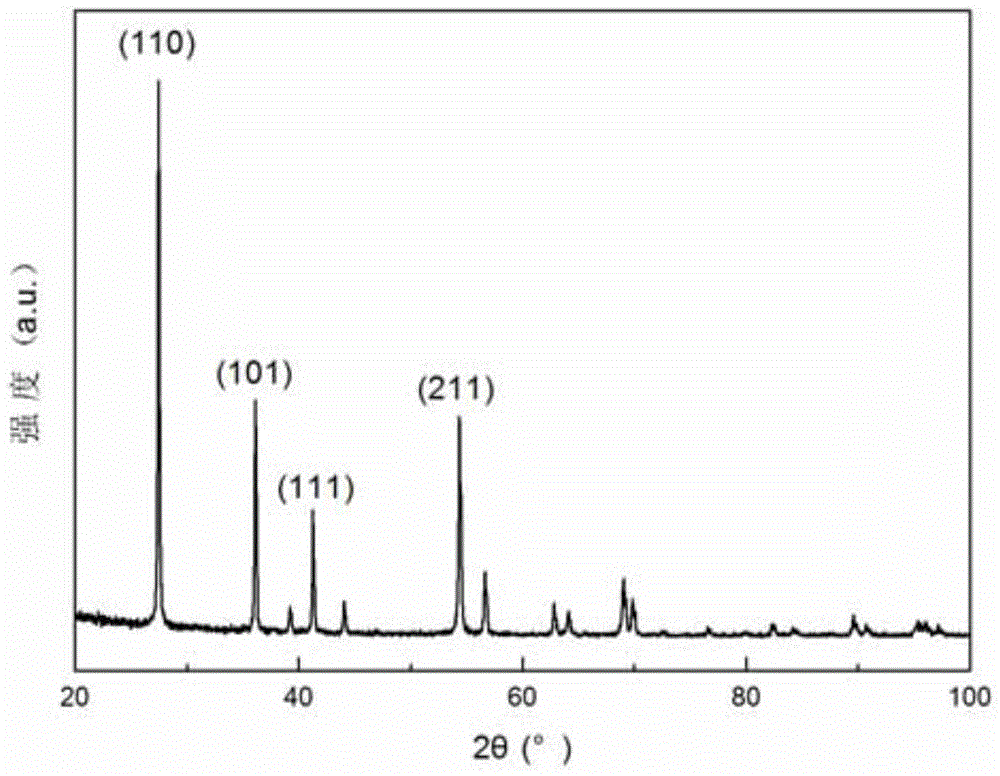

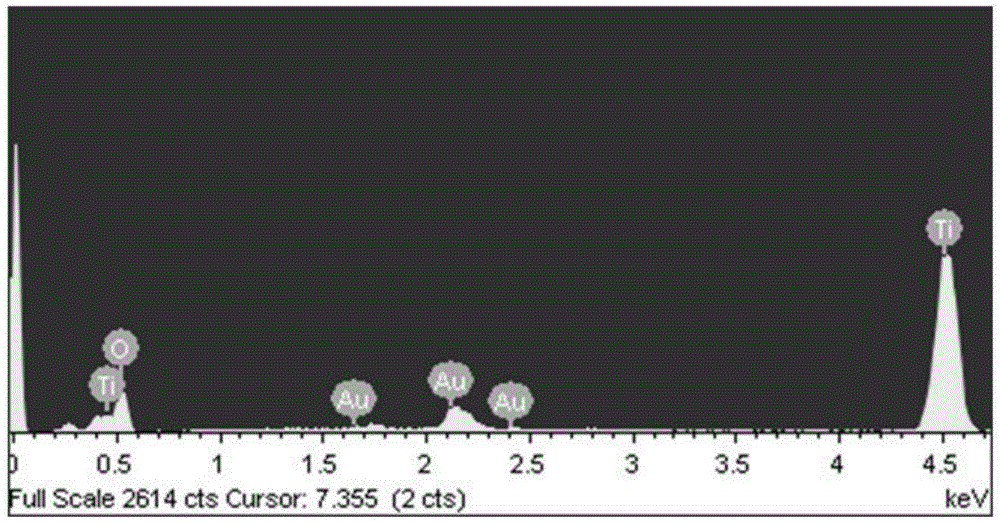

[0017] Specific embodiment one: the preparation method of boron-containing cross-shaped titanium dioxide photocatalyst of this embodiment is implemented according to the following steps:

[0018] 1. Put TiB 2 Add the powder into the reaction vessel, add a hydrochloric acid solution with a concentration of 0.2-0.8mol / L into the reaction vessel, and stir evenly with a magnetic force to obtain a turbid reaction liquid;

[0019] 2. Transfer the reaction turbid liquid obtained in step 1 into a polytetrafluoroethylene reaction kettle, seal it and put the reaction kettle into a constant temperature box for hydrothermal reaction at a temperature of 160-200°C to obtain a hydrothermal reaction solution ;

[0020] 3. Centrifuge the reaction liquid after hydroheating, wash the collected solid phase with deionized water for 3 to 5 times, and then wash with absolute ethanol for 3 to 5 times, and obtain boron-containing cross-shaped titanium dioxide photocatalyst after drying.

[0021] Thi...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that TiB in step one 2 The particle diameter of the powder is 100-300nm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, a hydrochloric acid solution with a concentration of 0.3-0.7 mol / L is added to the reaction vessel. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com