Fully-automatic drill electric-discharge machine

A fine-hole electric discharge machine, fully automatic technology, applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., can solve the problems of low processing yield, low degree of automation, and inability to judge whether the hole is opened, etc., to improve The effect of processing yield, reducing labor cost and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

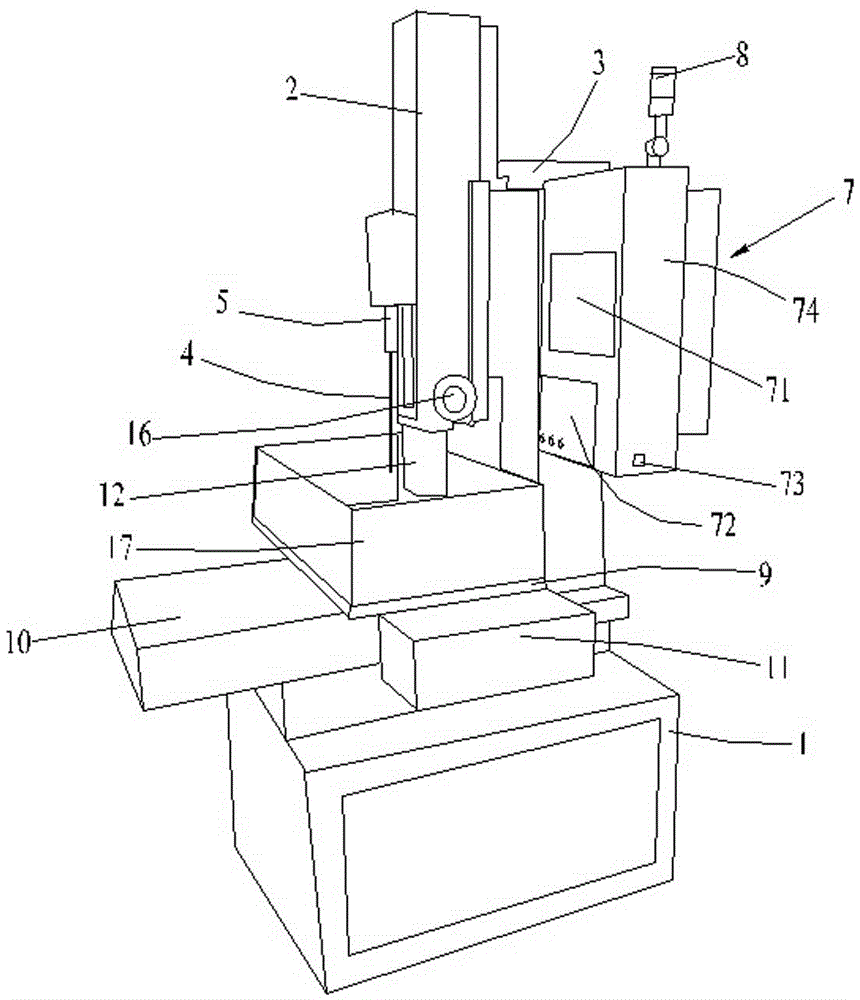

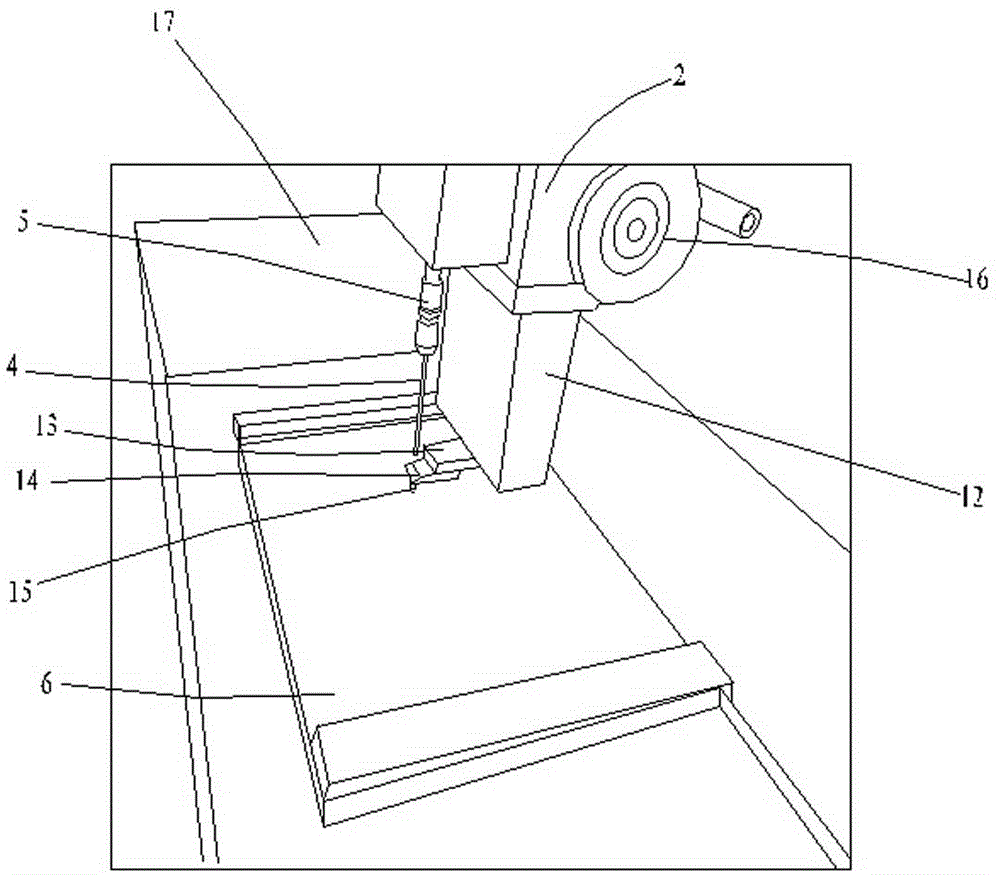

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a fully automatic fine-hole discharge machine, including a frame 1, a lifting plate 2, a positioning bracket 3, an electrode wire 4, a rotating head 5, a driving device and a control system 7, and the lifting plate 2 is arranged on a positioning On the bracket 3, the positioning bracket 3 is arranged on the frame 1, the rotating head 5 is connected with the lifting plate 2, and the rotating head 5 is connected with a driving device, the driving device is a servo motor, and the driving device can drive the rotating head 5 to rotate.

[0022] The electrode wire 4 is fixed on the rotating head 5 and extends toward the frame 1. The rotation of the rotating head 5 can drive the electrode wire 4 to rotate together, so that the electrode wire 4 contacts the workpiece to be processed, and the metal is etched by pulse spark discharge. Holes are thus formed on the workpiece to be machined. The electrode wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com