Tool beneficial for large circular pipe welding and welding deformation control and implementation method of tool

A technology for welding deformation and large-scale round pipes, which is applied in the field of steel structure manufacturing, can solve the problems of adverse effects on production quality and construction period, low one-time pass rate of round pipes, etc., and achieves outstanding substantive features, simple structure, and the effect of controlling welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

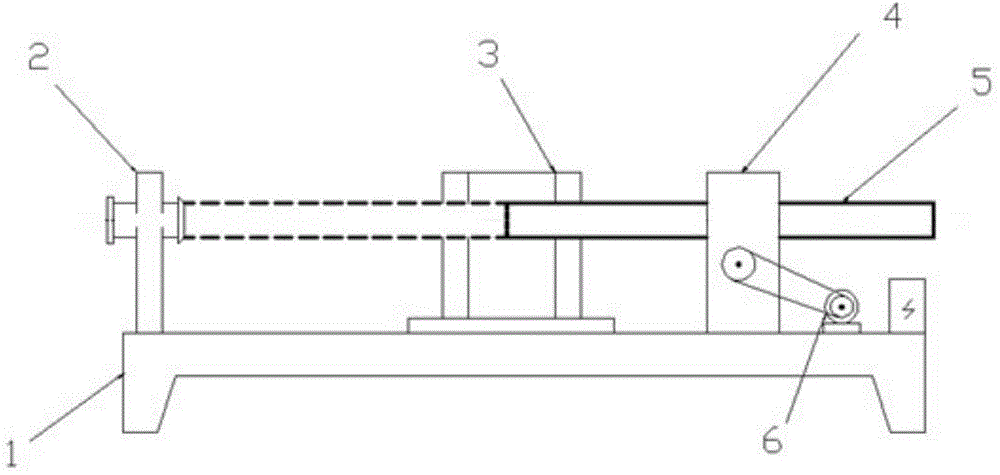

[0028] Such as figure 1 As shown, the embodiment of the present invention discloses a tool that is convenient for large-scale round pipe welding and welding deformation control, mainly comprising:

[0029] Workbench 1, preferably a horizontal workbench, is used to install various parts of the tooling to ensure the working plane of the tooling;

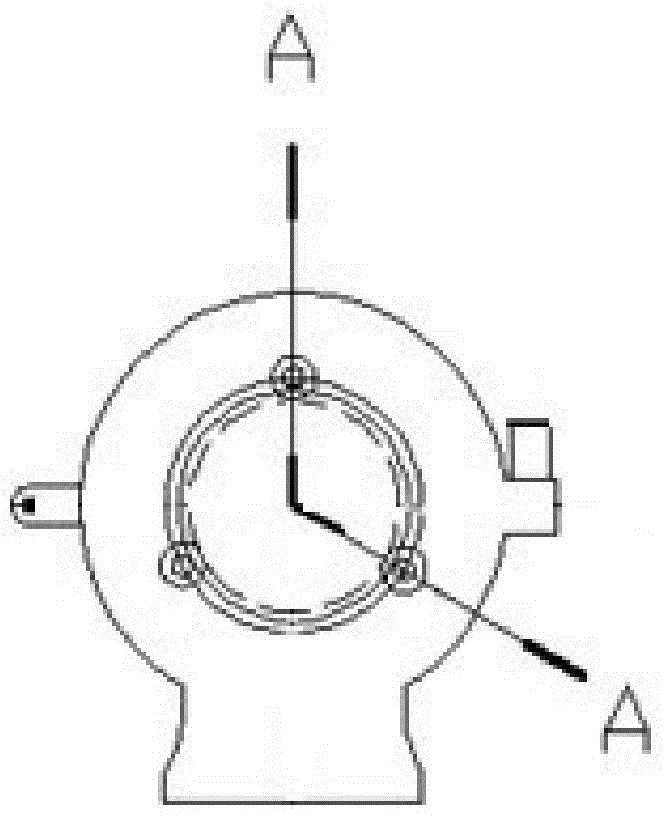

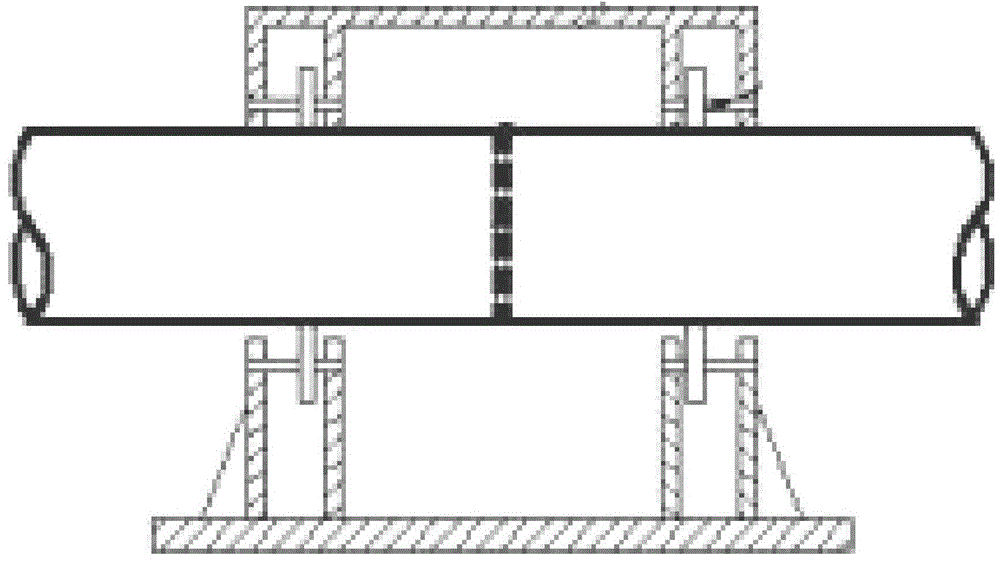

[0030] The first sleeve 2 is installed on one side of the workbench 1, and is provided with a bearing for fixing the round tube 5 and rotating around the center line of the round tube 5. It is in common with the double center frame 3 and the second sleeve 4. Complete the centering fixation of the two round pipes 5 to be connected;

[0031] The double center frame 3 is installed in the middle of the workbench 1, between the first sleeve 2 and the second sleeve 4, and a bearing for fixing the round tube 5 and rotating around the center line of the round tube 5 is arranged in it, Together with the first sleeve 2 and the second sleeve 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com