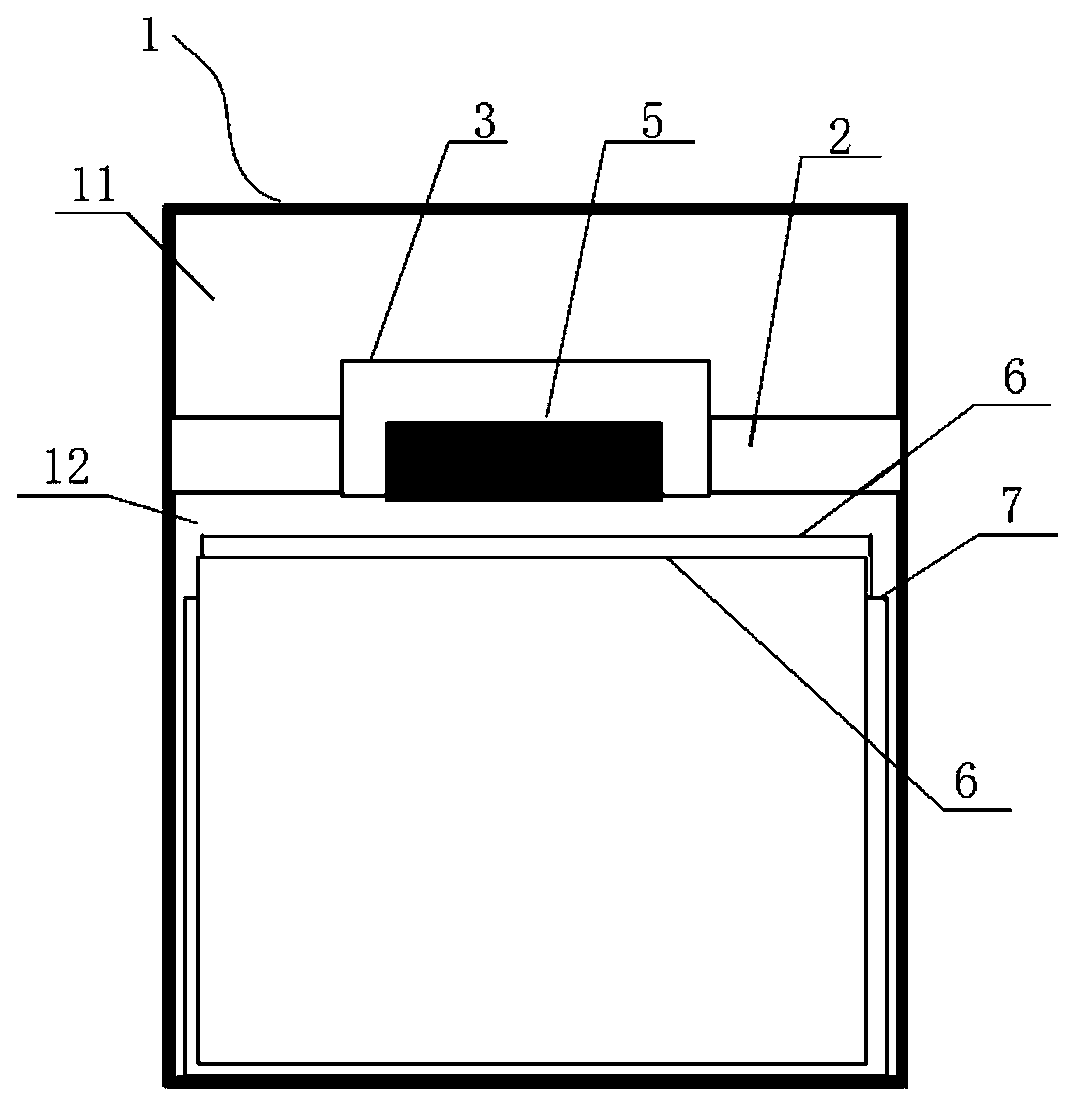

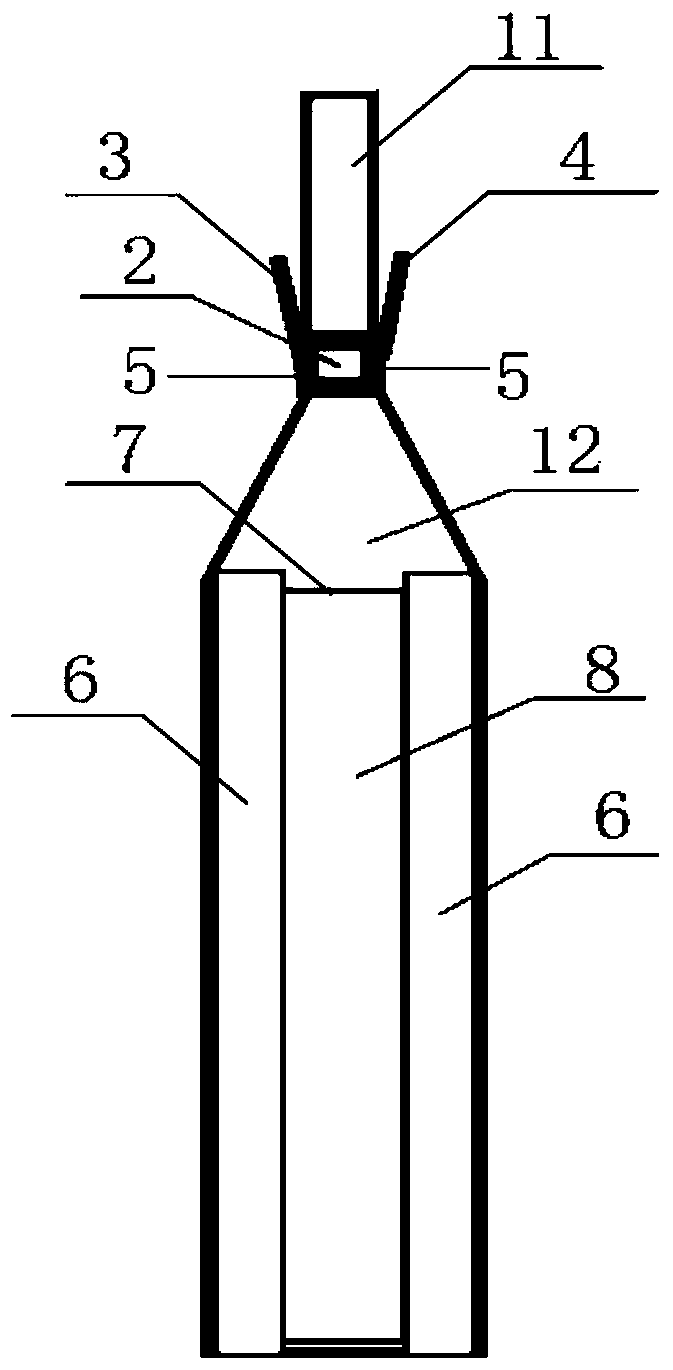

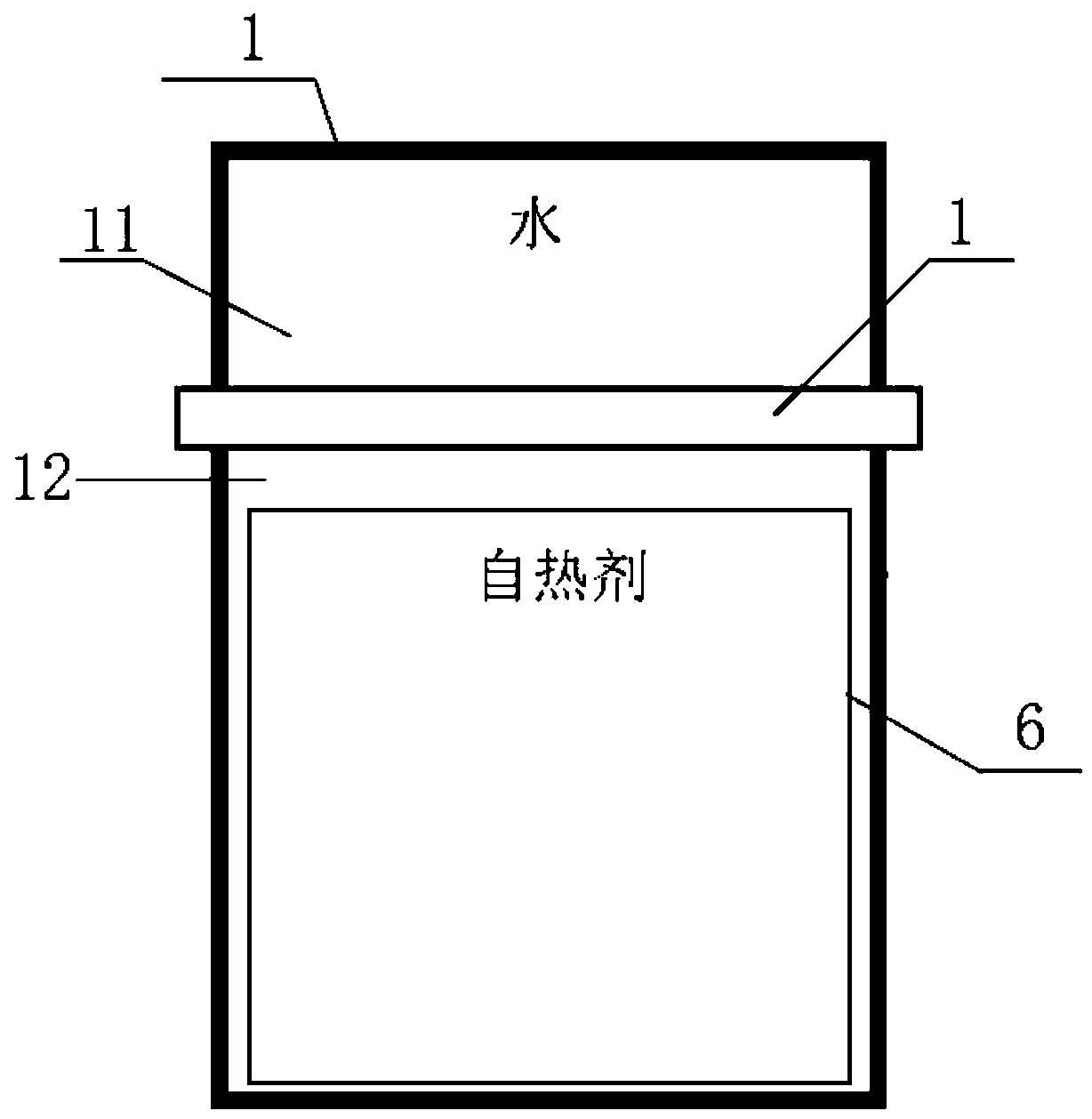

A self-heating food packaging

A food packaging and self-heating technology, applied in the field of food heating, can solve the problems of cumbersome operation, poor portability and safety, complex trigger structure, etc., and achieve the effect of convenient operation steps, simple production and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Take 10 grams of calcium oxide, 9 grams of anhydrous magnesium sulfate, and 3.6 grams of activated carbon, mix them evenly, add 24 ml of water, and heat up to above 100 degrees for 3 minutes, with a maximum temperature of 120 degrees.

Embodiment 2

[0081] Take 10 grams of calcium oxide, 3 grams of anhydrous magnesium sulfate, and 1 gram of activated carbon, mix them evenly, add 15 ml of water, reach 66 degrees in 1 minute, and reach a maximum temperature of 86 degrees.

Embodiment 3

[0083] Take 10 grams of calcium oxide, 10 grams of anhydrous magnesium sulfate, and 5 grams of activated carbon, mix them evenly, add 26 ml of water, and reach 88 degrees in 1 minute, with the highest temperature reaching 89 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com