Method for preparing Co3O4 nanoribbon

A technology of nanobelt and water bath method, which is applied in the field of preparation of Co3O4 nanobelt, can solve the problems of high temperature and high pressure reaction, complex and expensive, etc., and achieve the effect of mild reaction conditions, simple process and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A kind of Co 3 o 4 The preparation method of nanobelt adopts the water bath method to synthesize, and the steps are as follows:

[0019] 1) Dissolve 0.01 mol cobalt chloride hexahydrate in 60 mL of deionized water, stir magnetically at room temperature until completely dissolved, then add 0.1 mol urea, stir magnetically at room temperature to dissolve completely, and obtain a mixed solution;

[0020] 2) React the above mixed solution in a water bath at 90°C for 24 h to obtain a reaction solution;

[0021] 3) After the above reaction solution was left to stand for 20 minutes, centrifuge at 2000 r / min for 2 minutes, discard the supernatant, wash the obtained precipitate with water and absolute ethanol four times, and dry at 60°C 12 h, get Co(CO 3 ) 0.5 (OH)?0.11H 2 O precursor;

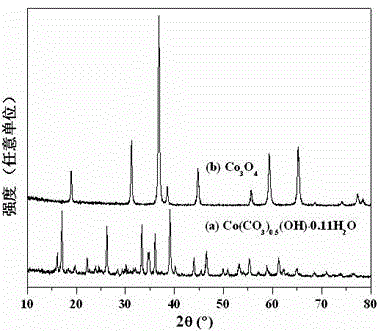

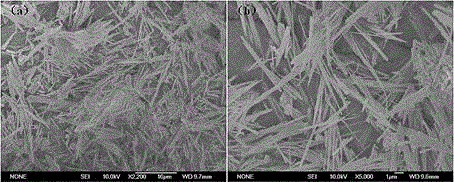

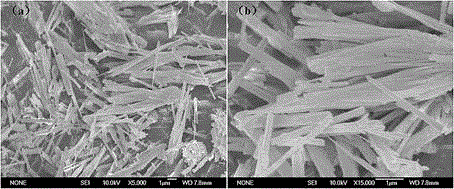

[0022] figure 1 For the preparation of Co(CO 3 ) 0.5 (OH)?0.11H 2 O precursor and Co 3 o 4 The XRD pattern (JCPDS card No.48-0083), wherein: figure 1 (a) is Co(CO 3 ) 0.5 (OH)?0.11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com