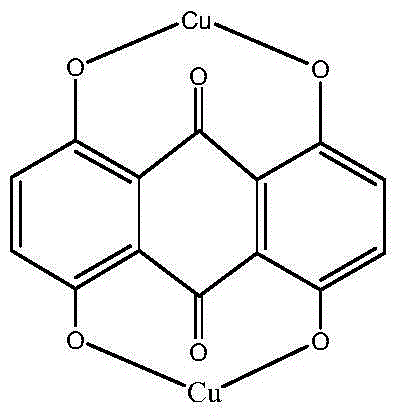

1,4,5,8-tetrahydroxyanthraquinone copper compound as well as preparation method and application thereof

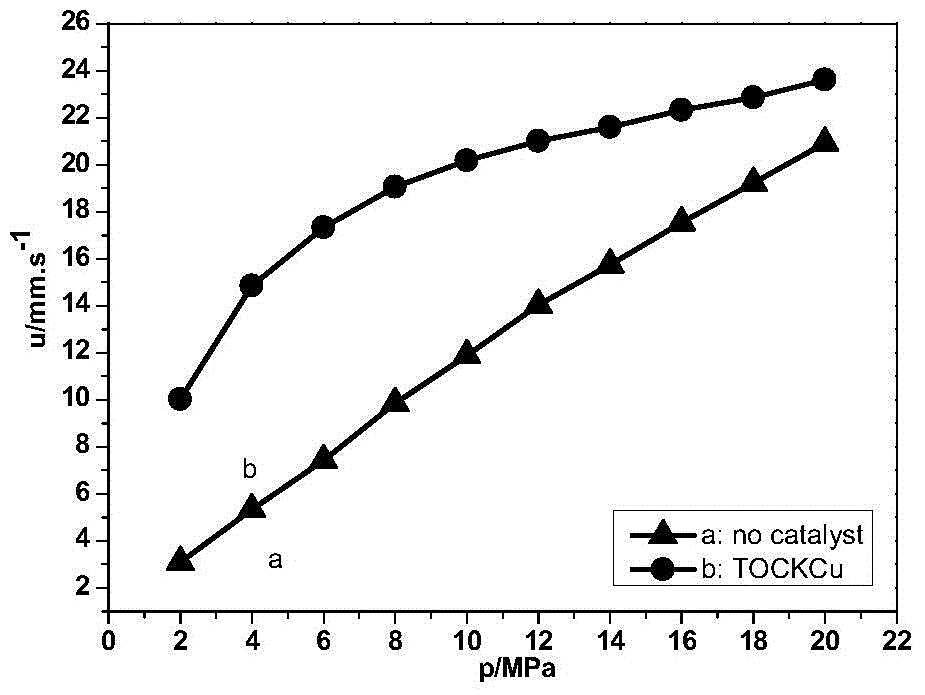

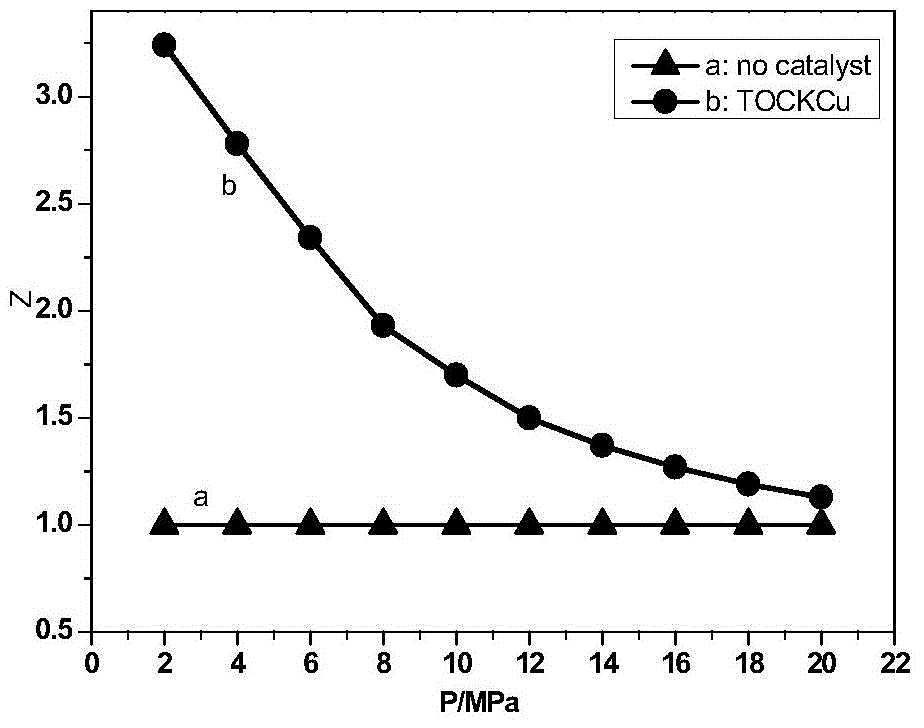

A technology of copper hydroxyanthraquinone and tetrahydroxyanthraquinone is applied in the field of catalysts for solid propellants, and can solve the problems of unsatisfactory green propellants, containing lead elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of 1,4,5,8-tetrahydroxyanthraquinone copper compound:

[0025] Weigh 0.01mol of 1,4,5,8-tetrahydroxyanthraquinone, disperse in 30mL of deionized water, adjust the pH value of the system with 0.04mol of sodium hydroxide; weigh 0.02mol of copper nitrate trihydrate with 30mL of deionized water Dissolve and configure into a solution, add it to 1,4,5,8-tetrahydroxyanthraquinone sodium, stir and mix evenly, raise the temperature to 65°C, react for 2 hours, then cool and stand still, wash the precipitate with deionized water several times, After filtering and drying, 3.72 g of dark red copper 1,4,5,8-tetrahydroxyanthraquinone can be obtained, with a yield of 94.2%.

[0026] Characterization of 1,4,5,8-tetrahydroxyanthraquinone copper compound

[0027] Infrared analysis

[0028] In the infrared spectrum of the raw material 1,4,5,8-tetrahydroxyanthraquinone, the peak of C=O appears at 1608cm -1 , the -OH peak on the anthraquinone ring appears at 3386cm -1 ,2964cm...

Embodiment 2

[0034] Preparation of 1,4,5,8-tetrahydroxyanthraquinone copper compound:

[0035] Weigh 0.01mol of 1,4,5,8-tetrahydroxyanthraquinone, disperse in 30mL of deionized water, adjust the pH value of the system with 0.038mol of potassium hydroxide; weigh 0.02mol of copper nitrate trihydrate with 30mL of deionized water Dissolve and configure into a solution, add it to 1,4,5,8-tetrahydroxyanthraquinone potassium, stir and mix evenly, raise the temperature to 60°C, react for 3 hours, then cool and stand still, wash the precipitate with deionized water several times, After filtering and drying, 3.50 g of dark red 1,4,5,8-tetrahydroxyanthraquinone copper can be obtained, with a yield of 88.6%.

Embodiment 3

[0037] Preparation of 1,4,5,8-tetrahydroxyanthraquinone copper compound:

[0038] Weigh 0.01mol of 1,4,5,8-tetrahydroxyanthraquinone, disperse in 30mL of deionized water, adjust the pH value of the system with 0.04mol of potassium hydroxide; weigh 0.02mol of copper sulfate pentahydrate with 30mL of deionized water Dissolve and configure into a solution, add it to 1,4,5,8-tetrahydroxyanthraquinone potassium, stir and mix evenly, raise the temperature to 75°C, react for 2.5 hours, then cool and stand still, and wash the precipitate with deionized water several times , filtered, and dried to obtain 3.65 g of dark red 1,4,5,8-tetrahydroxyanthraquinone copper, with a yield of 92.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com