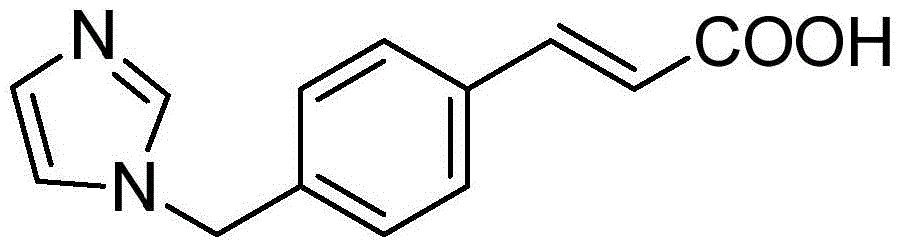

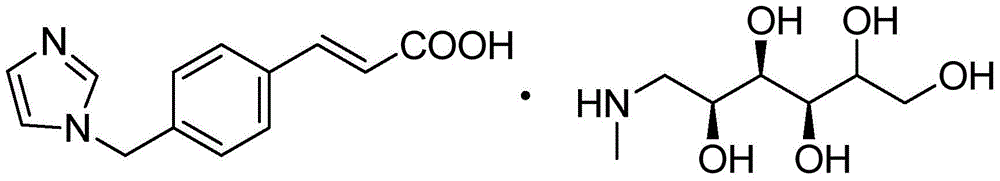

Ozagrel meglumine salt and its composition, preparation method and use

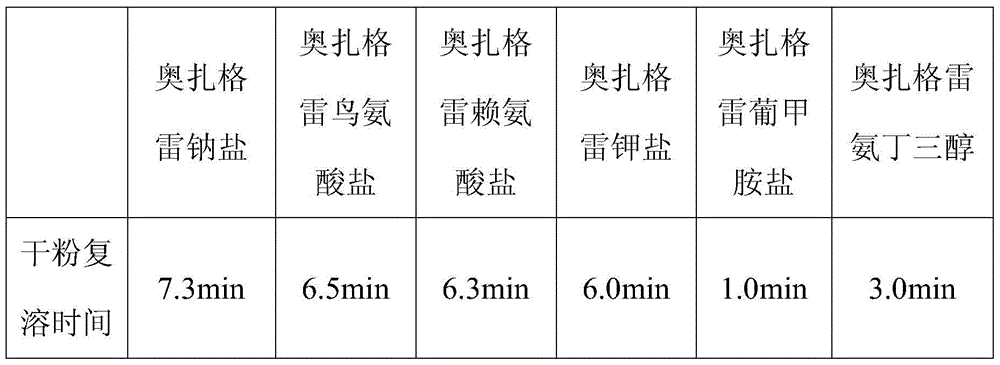

A technology of meglumine salt and meglumine salt, which can be used in the preparation of organic compounds, the preparation of aminohydroxy compounds, drug combination and other directions, can solve the problems of staying, poor taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Preparation of ozagrel meglumine salt:

[0080] At 10-15°C, add 60.00g (0.263mol) of meglumine to 95% ethanol, stir and heat to reflux, add 57.17g (0.250mol) of Ozagrel solid, the reaction solution is clear, keep warm and react, the reaction ends naturally When the temperature reaches 10-15°C, continue to stir and crystallize, filter with suction, rinse the filter cake with ethanol, and dry the filter cake at 40°C with blast to obtain a white powder. Add the crude product of ozagrel meglumine salt into 400ml of 50% ethanol at room temperature, heat and reflux until completely dissolved, then naturally cool down to room temperature and continue to stir and crystallize for 5h, filter with suction, rinse the filter cake with absolute ethanol, and keep the filter cake at 40°C Blow drying to obtain a white crystalline powder with a yield of 98.40 g, a yield of 92.77%, and a content of 100.2%. MS[M-H] - :422.02

[0081] 1 H-NMR (400MHz, DMSO-d 6 )δ (ppm): 7.75 (1H, s), 7...

Embodiment 2

[0085] Preparation of ozagrel meglumine salt:

[0086] At 10-15°C, add 60.00g (0.263mol) of meglumine to 90% methanol, stir and heat to reflux, add 41.31g (0.181mol) of Ozagrel solid, the reaction solution is clear, keep warm and react, the reaction ends naturally Lower the temperature to 10-15°C, continue to stir and crystallize, filter with suction, wash the filter cake with methanol, and dry the filter cake at 40°C with blast to obtain a white powder. Add the crude product of ozagrel meglumine salt into 300ml of 50% ethanol at room temperature, heat and reflux until completely dissolved, then naturally cool down to room temperature and continue to stir and crystallize for 5 hours, filter with suction, rinse the filter cake with methanol, and dry the filter cake by air at 40°C A white crystalline powder was obtained with a yield of 67.02 g, a yield of 87.44%, and a content of 99.7%.

Embodiment 3

[0088] Preparation of ozagrel meglumine salt

[0089] At 10-15°C, add 60.00g (0.263mol) of meglumine to 80% isopropanol, stir and heat to reflux, add 52.20g (0.229mol) of Ozagrel solid, the reaction solution is clear, keep warm for reaction, and react After the end, it will naturally cool down to 10-15°C, continue to stir and crystallize, filter with suction, rinse the filter cake with isopropanol, and dry the filter cake with air at 40°C to obtain a white powder. Add the crude product of ozagrel meglumine salt into 300ml of 50% ethanol at room temperature, heat and reflux until completely dissolved, then naturally cool down to room temperature and continue to stir and crystallize for 5h, filter with suction, rinse the filter cake with isopropanol, and keep the filter cake at 40°C Blow drying to obtain a white crystalline powder with a yield of 83.98 g, a yield of 86.72%, and a content of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com