Extraction process of ginseng saponin Rd

A ginsenoside and extraction process technology, applied in the field of extraction process of ginsenoside Rd, can solve the problems of complicated operation, low separation purity, unsuitable for industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

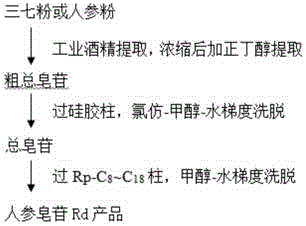

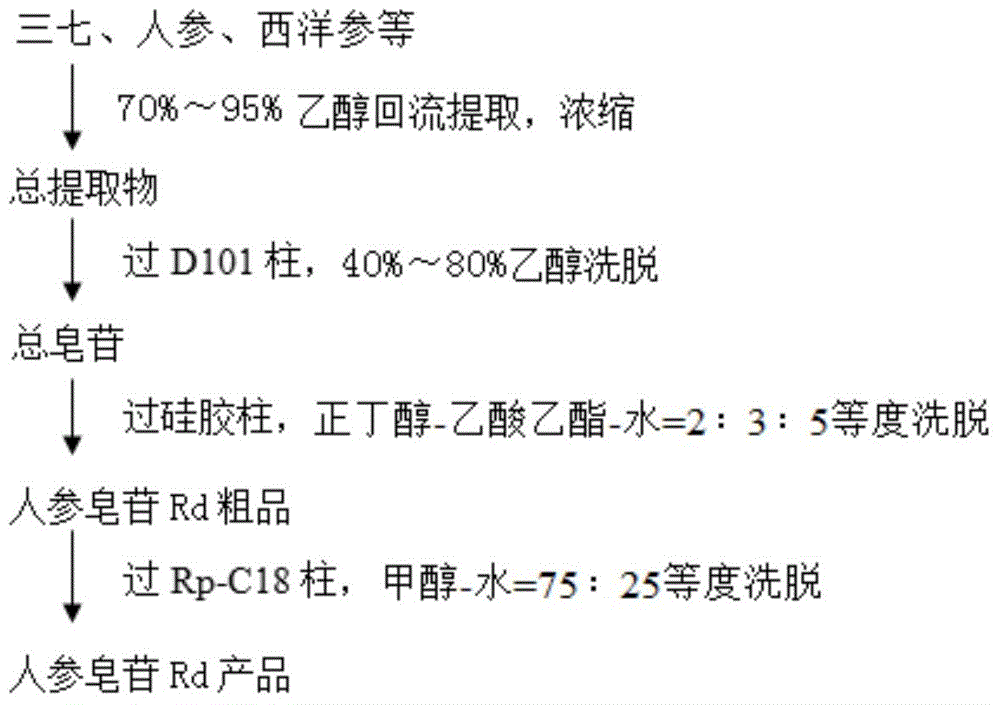

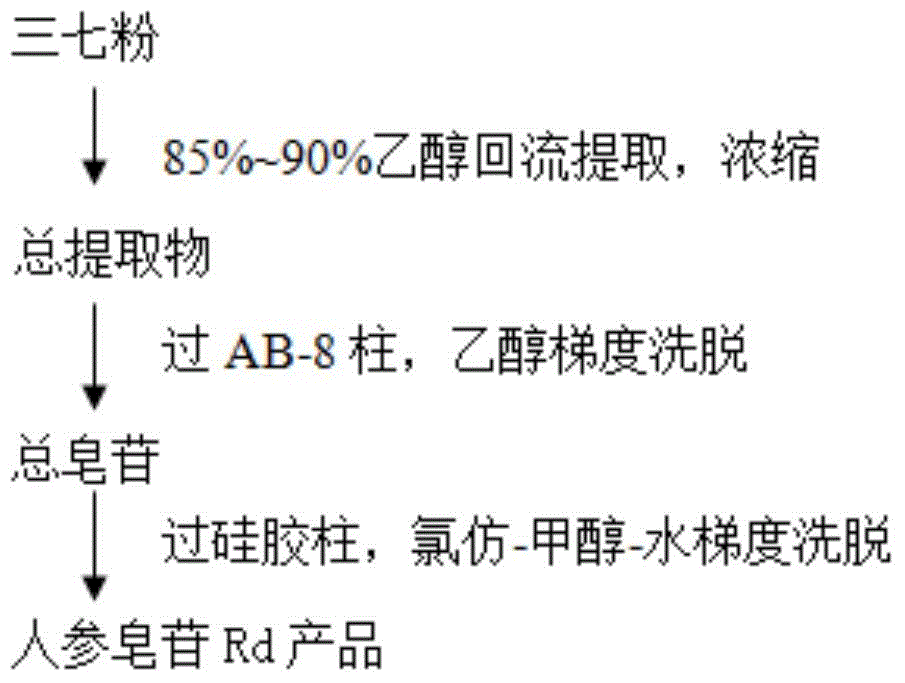

[0058] Embodiment 1 of the present invention: a kind of extraction process of ginsenoside Rd, such as figure 1 shown, including the following steps:

[0059] 1. Grind medicinal materials containing ginsenoside Rd (such as notoginseng, ginseng, American ginseng, etc.) into 50-mesh medicinal powder, add 2 times the amount of 85% ethanol, cold soak for 16 hours, filter, add 1.8 times the amount of 85% ethanol to the medicinal residue , reflux extraction 3 times, 2 hours each time, filter, combine the filtrates, recover ethanol and concentrate to extract with a relative density of 1.24 to obtain the total extract.

[0060] 2. Extraction of total saponins

[0061] (1) Column packing: fully wet the pre-treated D101 macroporous adsorption resin with ethanol, stir to remove air bubbles, pack the column, soak for 12 hours, wash with 95% ethanol until the effluent is mixed with water and does not become turbid, then use purified water Replace the ethanol in it until there is no alcoh...

Embodiment 2

[0073] Embodiment 2 of the present invention: a kind of extraction process of ginsenoside Rd, such as figure 1 shown, including the following steps:

[0074] 1. Grind medicinal materials containing ginsenoside Rd (such as notoginseng, ginseng, American ginseng, etc.) into 40-mesh medicinal powder, add 2 times the amount of 70% ethanol, cold soak for 15 hours, filter, add 1.8 times the amount of 70% ethanol to the medicinal residue , reflux extraction 3 times, 2 hours each time, filter, combine the filtrates, recover ethanol and concentrate to extract with a relative density of 1.15 to obtain the total extract.

[0075] 2. Extraction of total saponins

[0076] (1) Column packing: fully wet the pre-treated D101 macroporous adsorption resin with ethanol, stir to remove air bubbles, pack the column, soak for 12 hours, wash with 95% ethanol until the effluent is mixed with water and does not become turbid, then use purified water Replace the ethanol in it until there is no alcoh...

Embodiment 3

[0088] Embodiment 3 of the present invention: a kind of extraction process of ginsenoside Rd, such as figure 1 shown, including the following steps:

[0089] 1. Grind medicinal materials containing ginsenoside Rd (such as notoginseng, ginseng, American ginseng, etc.) into 60-mesh medicinal powder, add 2 times the amount of 95% ethanol, cold soak for 18 hours, filter, add 1.8 times the amount of 95% ethanol to the medicinal residue , reflux extraction 3 times, 2 hours each time, filter, combine the filtrates, recover ethanol and concentrate to extract with a relative density of 1.26 to obtain the total extract.

[0090] 2. Extraction of total saponins

[0091] (1) Column packing: fully wet the pre-treated D101 macroporous adsorption resin with ethanol, stir to remove air bubbles, pack the column, soak for 12 hours, wash with 95% ethanol until the effluent is mixed with water and does not become turbid, then use purified water Replace the ethanol in it until there is no alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com