Preparation method of octadecanedioic acid

A technology of octadecanedioic acid and octadecanedioic acid dimethyl, which is applied in the field of preparation of octadecanedioic acid, can solve the problems of being unsuitable for industrial production, octadecanedioic acid is not environmentally friendly, and the preparation cost is high. Achieve the effect of being beneficial to environmental protection, improving the purification steps, and shortening the synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of octadecanedioic acid, comprising the steps of:

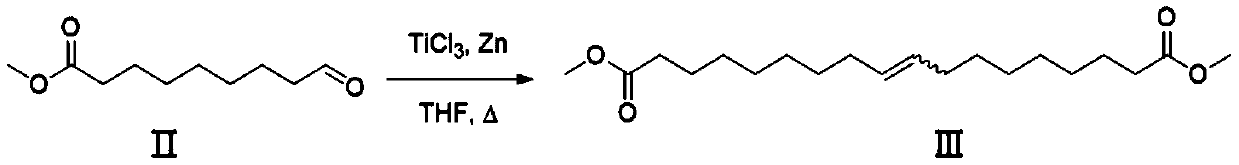

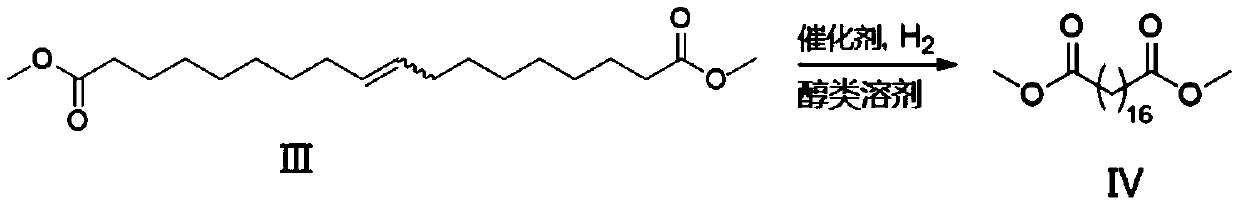

[0032] (1) prepare the coupling intermediate shown in formula III:

[0033]

[0034] Under nitrogen atmosphere, in a 1000 ml three-neck flask equipped with a mechanical stirring device, add 26 grams (400 mmol) of zinc powder and 250 ml of tetrahydrofuran solution, and add dropwise with a constant pressure dropping funnel under continuous stirring. Titanium trichloride liquid (wherein titanium trichloride 100 millimoles), be warming up to 45 ℃ after dropwise addition, heat and stir reaction 1 hour to generate zero-valent titanium;

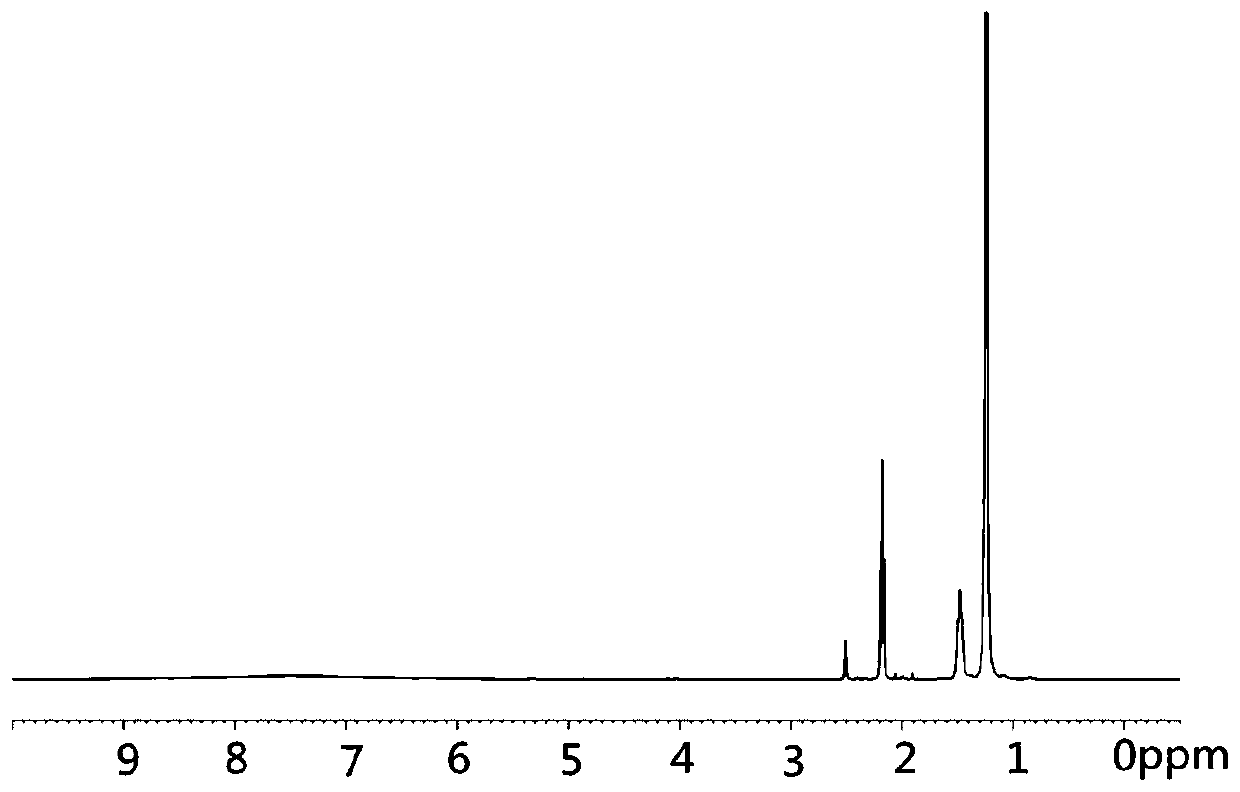

[0035] After cooling down to the range of 0°C to 5°C with an ice bath, add the starting material 9-oxononanoic acid methyl ester (18.6 grams, 100 mmoles) dropwise with a constant pressure dropping funnel. ) in tetrahydrofuran (50 milliliters), then warming up to 60°C and stirring for 16 hours to carry out McMurry coupling reaction (McMurry Coupling), after the reacti...

Embodiment 2

[0044] A preparation method of octadecanedioic acid, comprising the steps of:

[0045] (1) prepare the coupling intermediate shown in formula III:

[0046]

[0047] Under nitrogen atmosphere, in a 2000 ml three-necked flask equipped with a mechanical stirring device, add 39.2 g (600 mmol) of zinc powder and 500 ml of tetrahydrofuran solution, under continuous stirring, add dropwise with a constant pressure dropping funnel Titanium trichloride liquid (wherein titanium trichloride 200 millimoles), be warming up to 35 ℃ after dropwise addition, heat and stir reaction 4 hours to generate zero-valent titanium;

[0048] After cooling down to the range of 0°C to 5°C with an ice bath, add the starting material 9-oxononanoic acid methyl ester (37.2 grams, 200 mmoles) dropwise with a constant pressure dropping funnel. ) THF solution (100 milliliters), then warming up to 45 ° C and stirring for 24 hours to carry out McMurry coupling reaction (McMurry Coupling), after the reaction was...

Embodiment 3

[0057] A preparation method of octadecanedioic acid, comprising the steps of:

[0058] (1) prepare the coupling intermediate shown in formula III:

[0059]

[0060] Under nitrogen atmosphere, in a 2000 ml three-neck flask equipped with a mechanical stirring device, add 52.3 g (800 mmol) of zinc powder and 500 ml of tetrahydrofuran solution, under continuous stirring, add dropwise with a constant pressure dropping funnel Titanium trichloride liquid (wherein titanium trichloride 400 millimoles), be warming up to 60 ℃ of heating and stirring reaction for 1 hour to generate zero-valent titanium after dropwise addition;

[0061] After cooling down to the range of 0°C to 5°C with an ice bath, add the starting material 9-oxononanoic acid methyl ester (18.6 grams, 100 mmoles) dropwise with a constant pressure dropping funnel. ) in tetrahydrofuran (50 milliliters), then warming up to 70°C and stirring for 8 hours to carry out McMurry coupling reaction (McMurry Coupling), after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com