Random laser based on Fresnel reflection of fiber flat surface

A technology of Fresnel reflection and random lasers, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as lowering laser output efficiency and high-order laser lasing thresholds, achieve environmental temperature insensitivity, and improve output Efficiency, the effect of increasing the maximum output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the drawings.

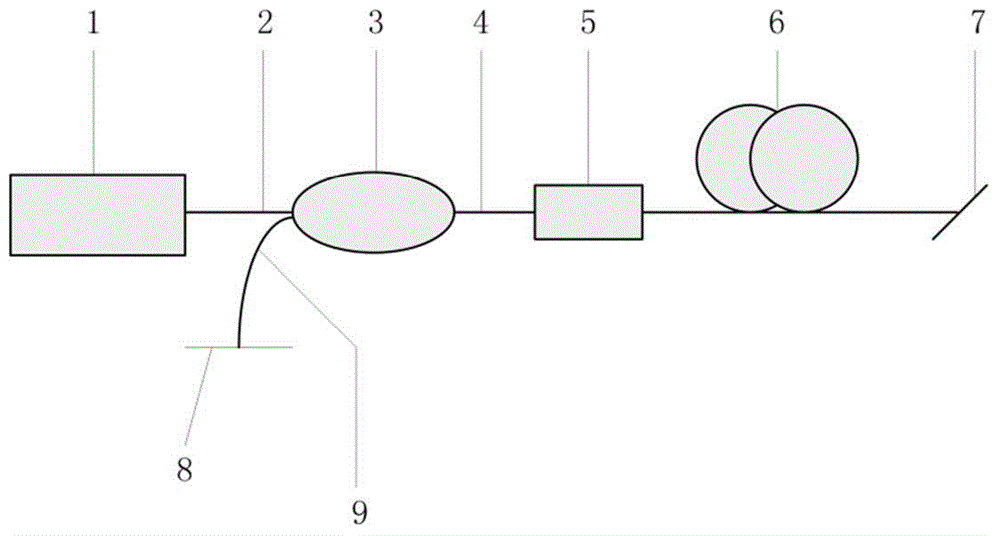

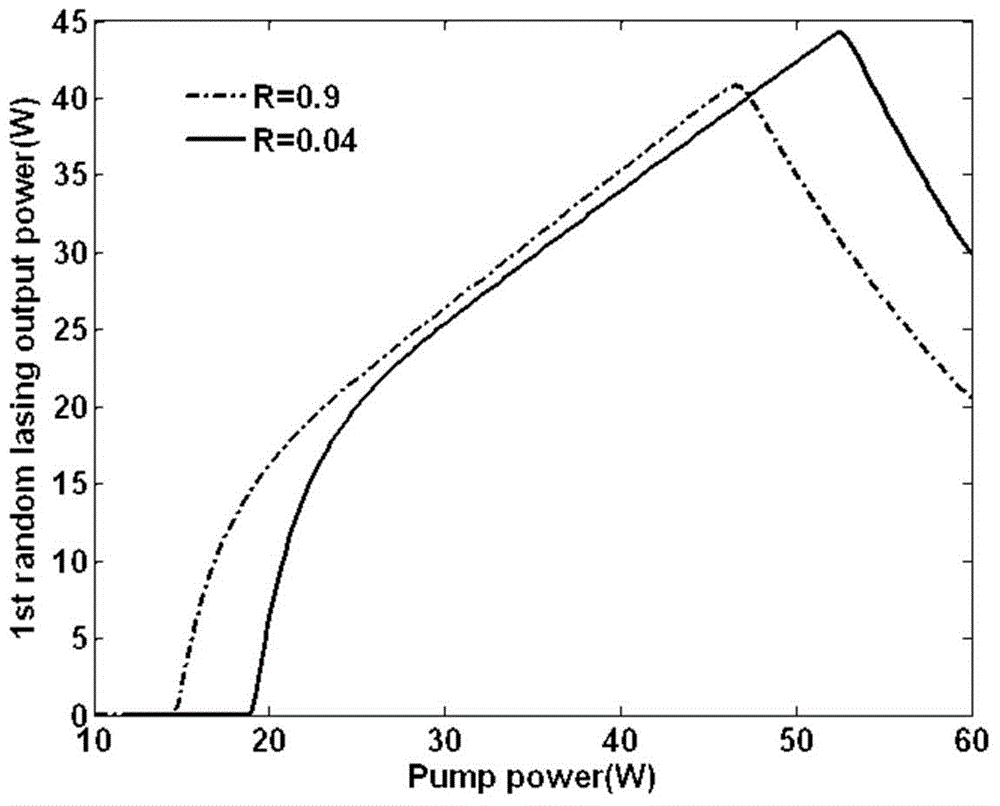

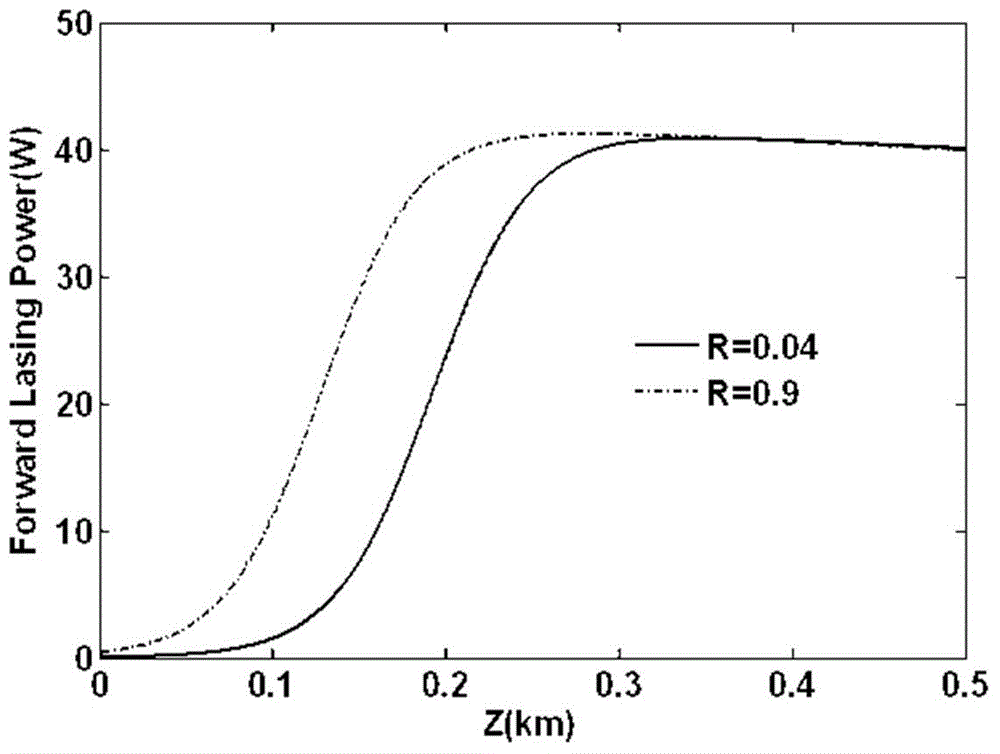

[0015] A random laser based on the Fresnel reflection of the flat end face of the fiber, comprising a pump light source (1), a wavelength division multiplexer (3), a band stop filter (5) and a single-mode fiber (6), and is characterized in : The wavelength of one port (2) of the wavelength division multiplexer WDM (3) corresponds to the wavelength of the pump light source, and the pump light source (1) is coupled into it through a port (2) of the wavelength division multiplexer WDM (3) In the single-mode fiber (6), a band stop filter (5) is connected between the common end (4) of the wavelength division multiplexer WDM (3) and the single-mode fiber (6), which can further increase the threshold of the second-order random laser , The fiber end (7) is an oblique end face, and its end face reflectivity is less than 10 -5 , Is the output port of the laser. The end of the two ports (9) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com