Sweet potato snack preparation method

A production method and a sweet potato technology, which are applied in the field of food processing, can solve the problems of difficulty in chewing, difficult to shape, and cannot supplement the nutrition of sweet potatoes, and achieve the effects of increasing nutrition and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

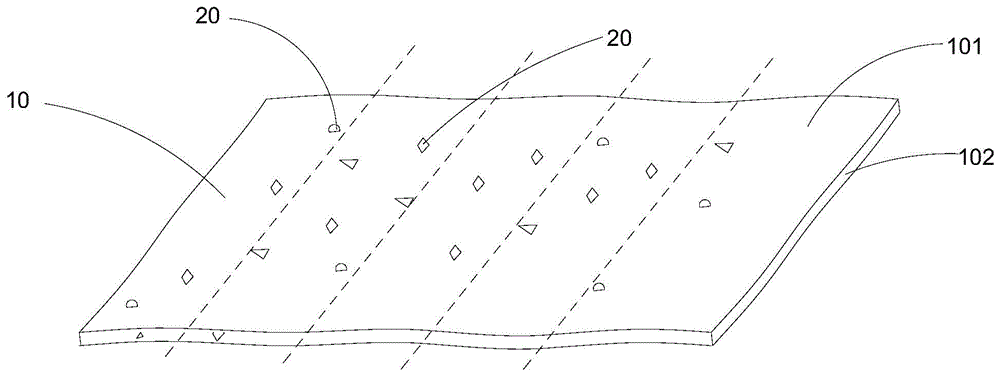

[0032] Example 1 Preparation of Sweet Potato and Sunflower Seed Snacks

[0033] Step a) In the initial processing, the mildewed and deteriorated sweet potatoes are removed, and 500 grams of red sweet potatoes are selected, weighed, and cleaned.

[0034] Step b) preprocessing, put the cleaned sweet potato into a steamer, add 300 grams of water, put the sweet potato on the hollow plate, do not directly contact with water, heat, and steam the sweet potato until cooked.

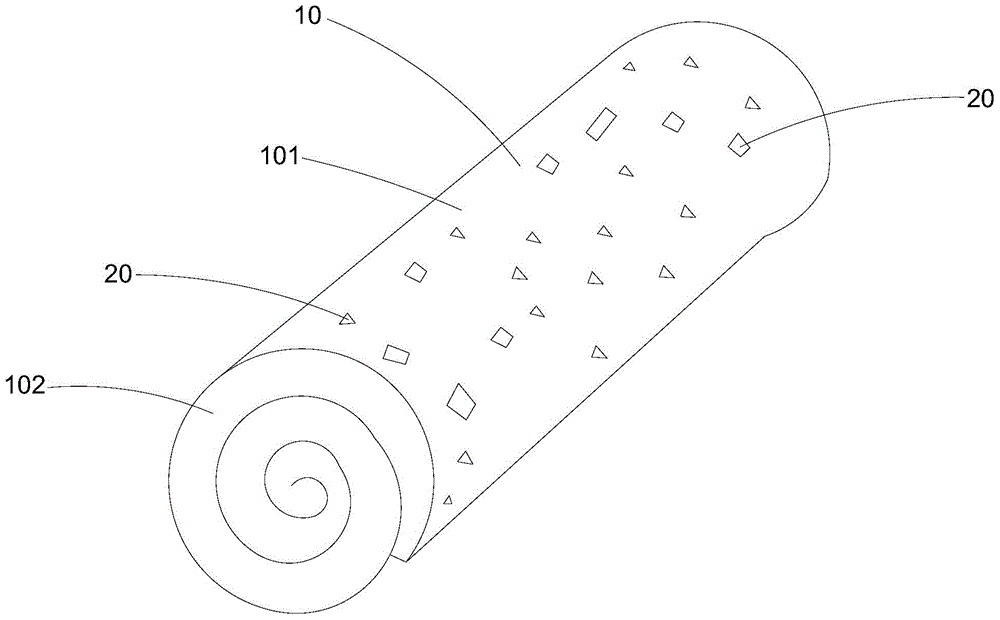

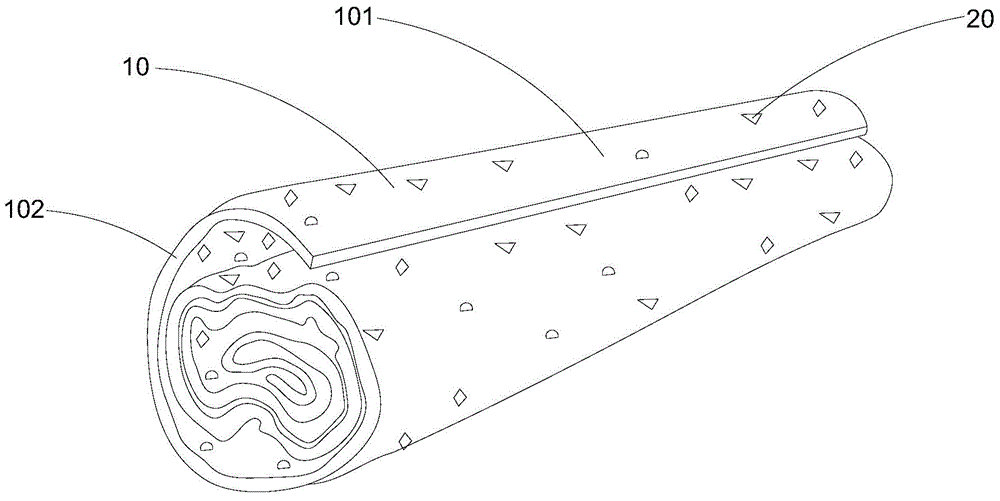

[0035] Step c) Reprocessing, mashing the steamed sweet potatoes into mud with a mortar, spreading the sweet potato mud on a clean plane to form a layered intermediate product; evenly spreading the melon seeds on the layered intermediate product to prepare a semi-finished product .

[0036] Step d) When the semi-finished product is dried until it becomes hard, it is cut into various shapes and packed into bags.

Embodiment 2

[0037] Example 2 Preparation of Sweet Potato Peanut Snacks

[0038] Step a) In the initial processing, the mildewed and deteriorated sweet potatoes are removed, and 500 grams of red sweet potatoes are selected, weighed, and cleaned.

[0039] Step b) preprocessing, put the cleaned sweet potato into a steamer, add 300 grams of water, put the sweet potato on the hollow plate, do not directly contact with water, heat, and steam the sweet potato until cooked.

[0040] Step c) Reprocessing, mashing the steamed sweet potatoes into mud with a mortar, spreading the sweet potato mud on a clean plane to form a layered intermediate product; crushing the peanuts and evenly spreading them on the layered intermediate product semi-finished products.

[0041] Step d) When the semi-finished product is dried until it becomes hard, it is cut into various shapes and packed into bags.

Embodiment 3

[0042] Example 3 Preparation of sweet potato and hawthorn snacks

[0043] Step a) In the initial processing, the mildewed and deteriorated sweet potatoes are removed, and 500 grams of red sweet potatoes are selected, weighed, and cleaned.

[0044] Step b) preprocessing, put the cleaned sweet potato into a steamer, add 300 grams of water, put the sweet potato on the hollow plate, do not directly contact with water, heat, and steam the sweet potato until cooked.

[0045] Step c) Reprocessing, mash the steamed sweet potatoes into mud with a mortar; remove the core of the hawthorn, put it in a steamer and cook until cooked, boil it into juice, then mash it into a mud with a mortar, mix with the sweet potato mash or Mix the sweet potato mash, spread the sweet potato mash mixed with the hawthorn mash on a clean flat surface to form a semi-finished product.

[0046] Step d) When the semi-finished product is dried until it becomes hard, it is cut into various shapes and packed into b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com