Sericin protein microneedle for drug delivery and preparation method thereof

A sericin and microneedle technology, applied in the field of biomedical engineering, can solve the problems of uncontrollable slow release process, poor biocompatibility, large trauma, etc., and achieve the effect of good application development prospect, good performance and easy preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

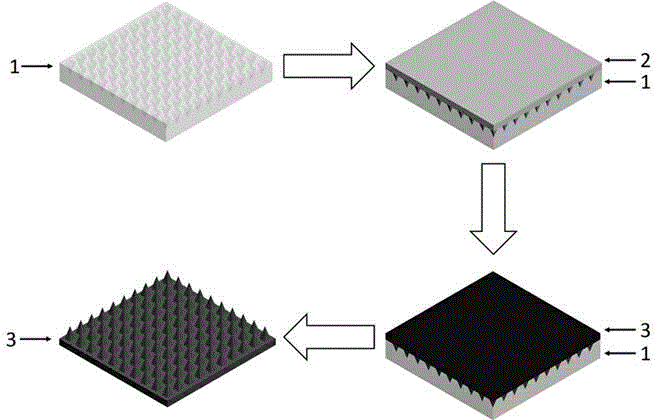

Image

Examples

Embodiment 1

[0031] (1): Prepare sericin solution;

[0032] Take 20 mg of sericin protein (molecular weight 5 kDa) and dissolve it in 200.00 mL of water, and make the solution uniform by magnetic stirring at a speed of 50 r / min for 0.1 h.

[0033] (2) Dissolve 0.1 g of amoxicillin in the sericin solution prepared by the above method, and make the solution uniform by magnetic stirring at a speed of 300 r / min for 1 h.

[0034] (3) Take 2mL of the amoxicillin sericin solution obtained in step (2), and slowly pour it into 4cm 2 The microneedle impression was dried at 25°C under normal pressure (0.1 MPa) for 24 hours, and cured in methanol for 1 minute.

[0035] (4) Detach the sericin microneedles from the female mold by mechanical stripping.

[0036] (5) Put the tip of the amoxicillin sericin microneedle upwards and place it horizontally to obtain the sericin egg wrapped with amoxicillin drug.

[0037] White microneedles and sericin microneedles have a length of 0.1-2 mm, a tip diameter of ...

Embodiment 2

[0040] (1): Prepare sericin solution;

[0041] Take 10 g of sericin (molecular weight 10 kDa) and dissolve it in 20.00 mL of water, and make the solution uniform by magnetic stirring at 1500 r / min for 48 h.

[0042] (2) Dissolve 0.5 g of amoxicillin in the sericin solution prepared by the above method, and make the solution uniform by magnetic stirring at a speed of 300 r / min for 1 h.

[0043] (3) Take 2mL of the amoxicillin sericin solution obtained in step (2), and slowly pour it into 4cm 2 The microneedle impression was dried at 25°C under normal pressure (0.1 MPa) for 24 hours, and cured in methanol for 60 minutes.

[0044] (4) Detach the sericin microneedles from the female mold by mechanical stripping.

[0045] (5) Put the tip of the amoxicillin sericin microneedle upwards and place it horizontally to obtain the sericin microneedle wrapped with amoxicillin drug.

[0046] (5) Gently press the amoxicillin sericin microneedle needle tip down into the patient's skin infec...

Embodiment 3

[0048] (1): Prepare sericin solution;

[0049]5 g of sericin (molecular weight 150 kDa) was dissolved in 20.00 mL of water, and the solution was homogenized by magnetic stirring at 800 r / min for 20 h.

[0050] (2) Dissolve 0.2 g of cephalosporin in the sericin solution prepared by the above method, and make the solution uniform by magnetic stirring at a speed of 300 r / min for 1 h.

[0051] (3) Take 2 mL of the cephalosporin solution obtained in step (2), and slowly pour it into 4 cm 2 Freeze-dried for 24 hours (the cold trap temperature is -55°C and the air pressure is 0.5Pa). Cured by steam annealing. The steam annealing temperature was 27 °C, the time was 48 h, and the pressure was 0.05 kPa.

[0052] (4) Detach the sericin microneedles from the female mold by mechanical stripping.

[0053] (5) Place the cephalosporin microneedle with the tip upward and place it horizontally to obtain the sericin microneedle encapsulating the cephalosporin drug.

[0054] (5) With the tip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com