Metal sheet stretching energy-saving method

A metal sheet and stretching force technology, applied in the field of stretching technology, can solve the problems of increasing the damage probability of machine parts, easy cracking of products, and back pressure loss, etc., to reduce equipment operation and maintenance costs, and the temperature is not easy to rise and reduce The effect of equipment operation dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

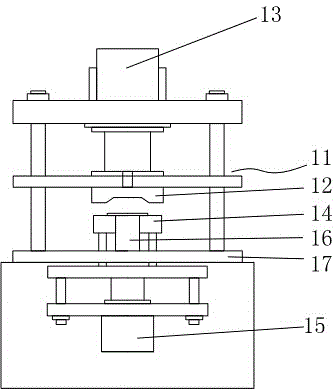

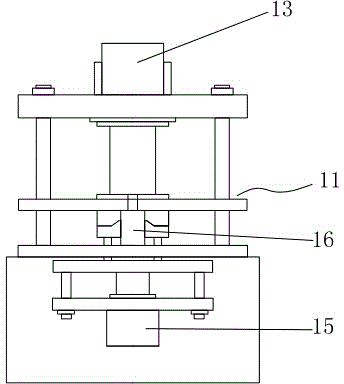

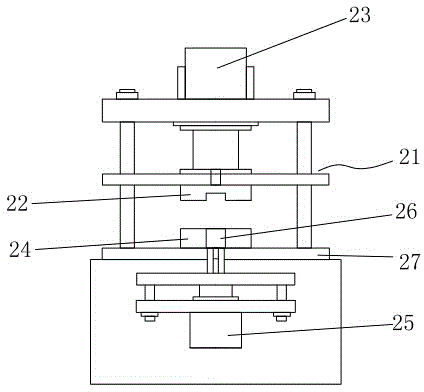

[0027] Such as image 3 , 4 As shown, the present invention discloses an energy-saving method for drawing metal sheets, which is applied to a drawing machine with a fixed blank holder and a punch core that can move up and down. The specific structure of the stretching machine includes a frame 21, a female die 22, a blanking cylinder 23, a blanking ring 24, a stretching cylinder 25, a punch core 26 and a worktable 27 arranged in the middle of the frame. The blank holder 24 is fixedly installed on the worktable 27. The die 22 and the punch core 26 are respectively installed on the piston rods of the blanking cylinder 23 and the stretching cylinder 25. The blanking cylinder 23 is installed on the upper part of the frame and can drive the concave mold 22 to move up and down. The stretching cylinder 25 is installed on the machine. The lower part of the frame can drive the punch core 26 to move up and down relative to the blank holder 24.

[0028] Such as Figure 5 , 6 As shown, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com