Chip fixing device and preparation method for invalid analysis sample

A technology for failure analysis samples and fixtures, which is applied in the semiconductor field, can solve problems such as the inability to realize automatic chemical grinding, and achieve the effects of easy operation, high success rate, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

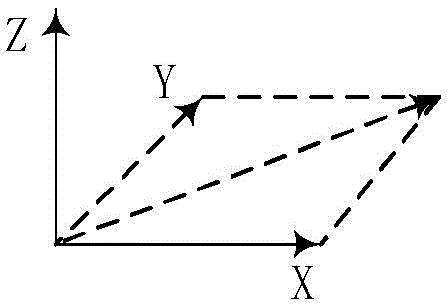

[0036] It can be seen from the background technology that during the preparation of the failure analysis sample, it is necessary to face the front of the sample to the chemical grinder table, and manually press the back of the sample to complete the grinding of the sample, thereby preparing the failure analysis sample. The inventor found that in the grinding process, a frictional force opposite to the rotation direction of the chemical grinding machine table will be produced, such as figure 1 A force in the X direction, and a centrifugal force perpendicular to the direction of rotation, such as figure 1 For the force in the Y direction, to ensure the smoothness of the grinding process, it is necessary to apply force from the outside to balance the friction and centrifugal force. In the process of manual grinding, the force applied from the outside is in the direction perpendicular to the chemical grinding machine table. Such as figure 1 The force in the Z direction, the exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com