Injection molding production method of transparent product with thick-walled curved surface structure

A technology for injection molding and transparent parts, which is applied in the field of injection molding of transparent plastic parts. It can solve the problems of difficult realization of curved surface structure and small size of thick-walled transparent parts, so as to avoid vacuum bubbles and reduce warping deformation. and optical imperfections for precisely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

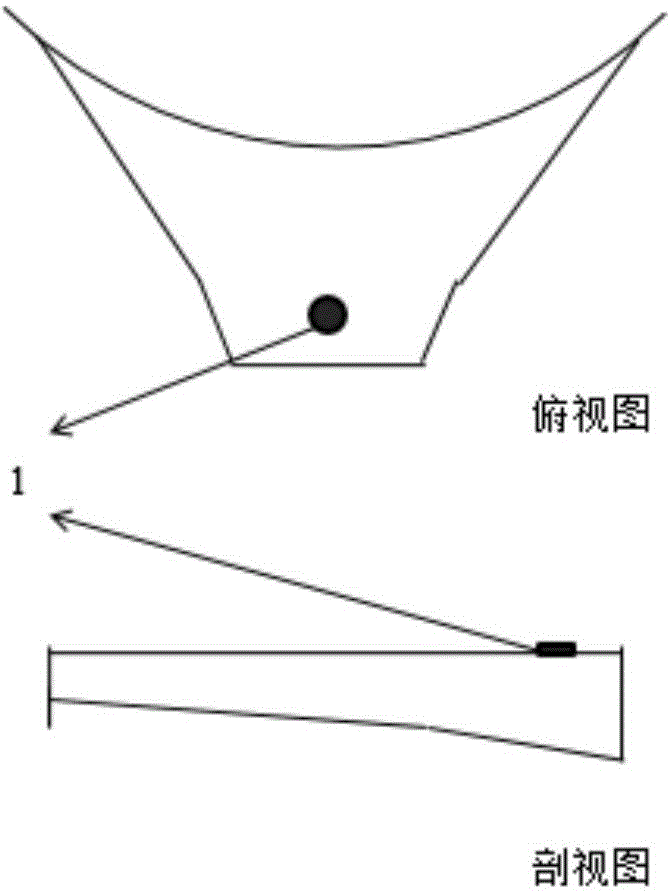

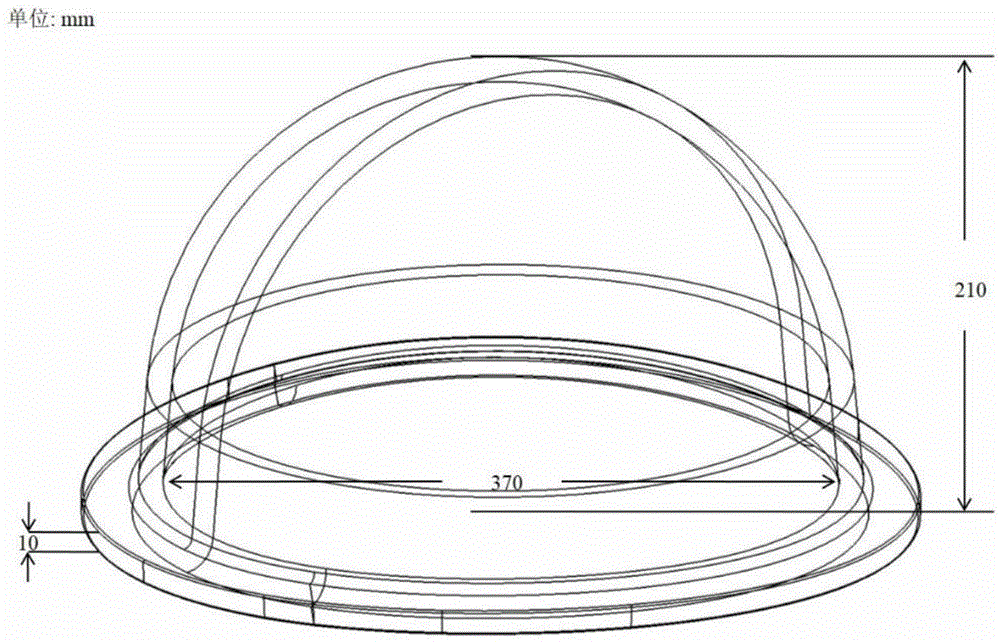

[0026] The thickness of the injection molded part is 10mm, and the shape of the injection molded part is as attached figure 2 shown;

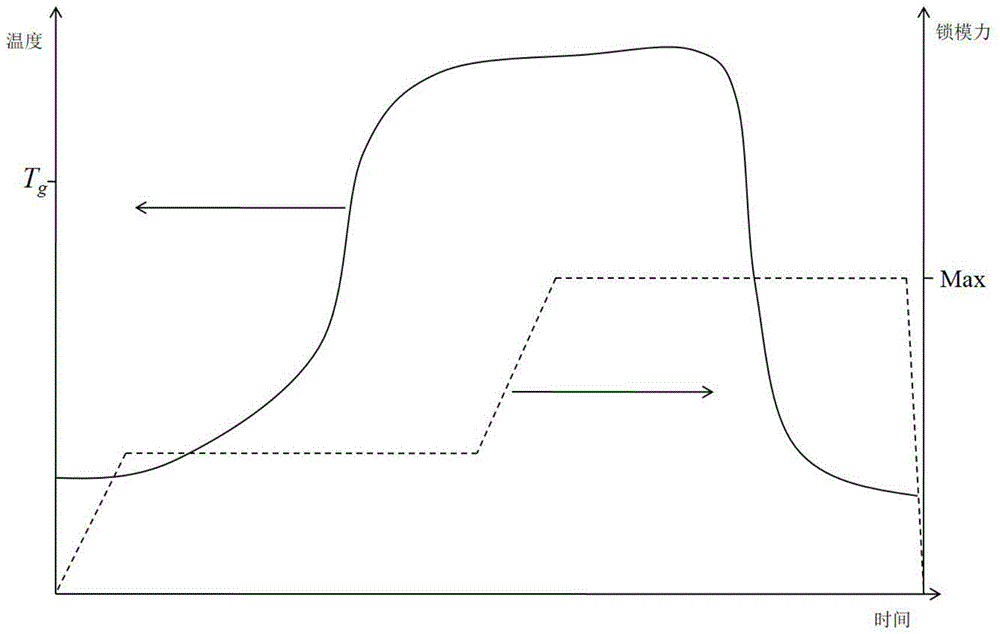

[0027] (1) The gate of the injection molded part is located in the edge area, and its shape adopts a slit expansion structure with a continuous step change in thickness, as shown in the attached figure 1 As shown, the glue injection point 1 is located on the side close to the maximum thickness of the gate, the maximum thickness of the gate is 20mm, the minimum thickness of the gate is 7mm, and the length of the gate is 50mm; Move the platen back to expand the mold cavity until the parting surface gap is 5mm, the mold temperature rises to 160°C, and the screw advances 5mm / s-10mm / s-20mm / s low-speed multi-stage injection filling. By adjusting the screw back pressure and the screw Stroke and other parameters, so that the injection volume is 108% of conventional injection molding; (3) The holding pressure of the screw after filling is 105%-120% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com