Method for separating and purifying high-content picloram from picloram production waste residues

A kind of technology of amiloride and clopyralid, applied in the field of reuse of amiloride production waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

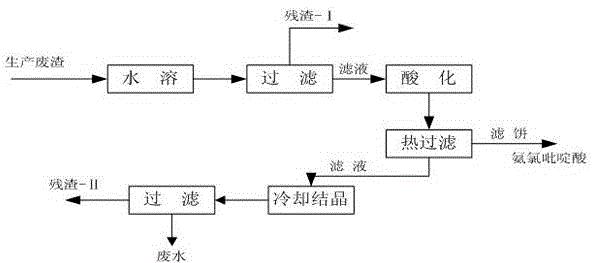

Method used

Image

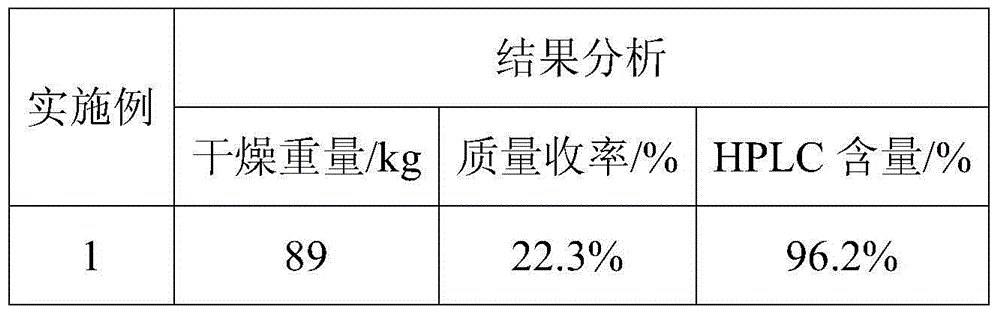

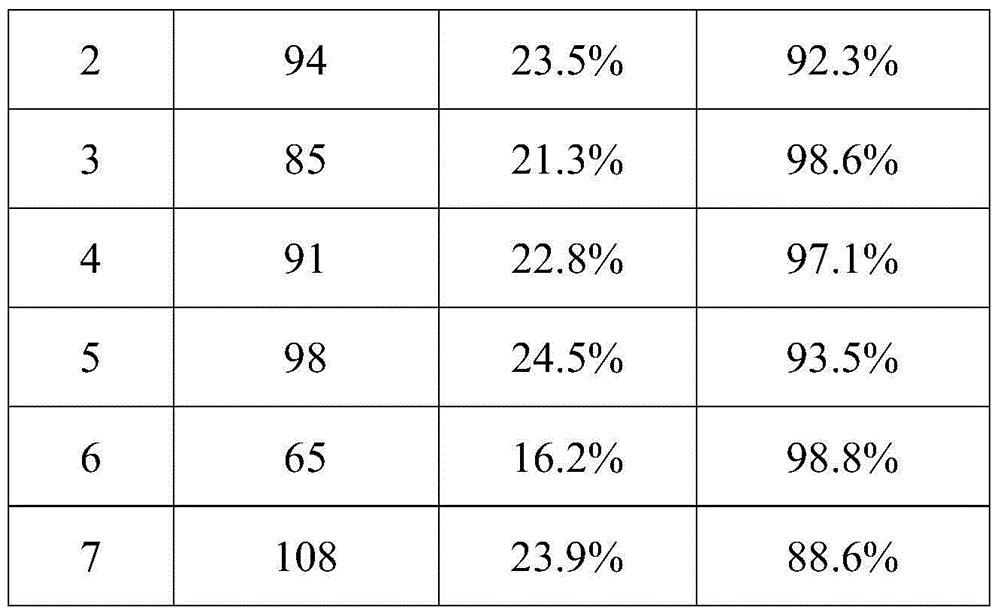

Examples

Embodiment 1

[0023] Add 600kg of tap water into the 1500L reactor, start stirring, then put 400kg of amiloride production waste residue (wet residue, water content is 50-55%), heat up the material to 80-90°C, keep stirring for 30 minutes, Then start the filter device while it is hot, and slowly cool the material while circulating the filter, and stop the filter when the temperature of the clear liquid cools below 30°C; the filter cake is the residue-I.

[0024] The filtered clear liquid is transferred to the acidification kettle, the material is heated to 85°C, and metered hydrochloric acid is added to ensure that the pH of the feed liquid is not higher than 2, and it is filtered while it is hot at 85°C, and the filtrate is cooled, crystallized, and filtered. It is the residue-II, and the filter cake is amiloride after washing with water, the HPLC content is 96.3%, and the weight after drying is 89kg;

Embodiment 2

[0026] Add 700kg of tap water to the 1500L reactor, start stirring, then put 400kg of amiloride production waste residue (wet residue, water content is 50-55%), heat the material to 80-90°C, keep stirring for 30 minutes, Then start the filter device while it is hot, and slowly cool the material while circulating the filter, and stop the filter when the temperature of the clear liquid cools below 30°C; the filter cake is the residue-I.

[0027] The filtered clear liquid is transferred to the acidification tank, the temperature of the material is raised to 85°C, and a metered amount of hydrochloric acid is added to ensure that the pH of the feed liquid is not higher than 2, and the temperature is lowered to 65°C to filter while it is hot, and the filtrate is cooled, crystallized, and filtered. , which is residue-II, the filter cake is amiloride after washing with water, the HPLC content is 92.3%, and the weight after drying is 94kg;

Embodiment 3

[0029] Add 500kg of tap water to the 1500L reactor, start stirring, then put 400kg of amiloride production waste residue (wet residue, water content is 50-55%), heat the material to 80-90°C, keep stirring for 30 minutes, Then start the filter device while it is hot, and slowly cool the material while circulating the filter, and stop the filter when the temperature of the clear liquid cools below 30°C; the filter cake is the residue-I.

[0030] The filtered clear liquid is transferred to the acidification kettle, the material is heated to 85°C, and metered hydrochloric acid is added to ensure that the pH of the feed liquid is not higher than 2, and it is filtered while it is hot at 85°C, and the filtrate is cooled, crystallized, and filtered. It is the residue-II, and the filter cake is amiloride after washing with water, the HPLC content is 98.6%, and the weight after drying is 85kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com