A kind of photochromic fluorocarbon resin and its preparation method and application

A fluorocarbon resin and photochromic technology, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, coatings, etc., can solve the problems of not being resistant to wiping, not being resistant to organic solvents, and not being able to achieve text communication, etc., to achieve extremely easy The effect of erasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

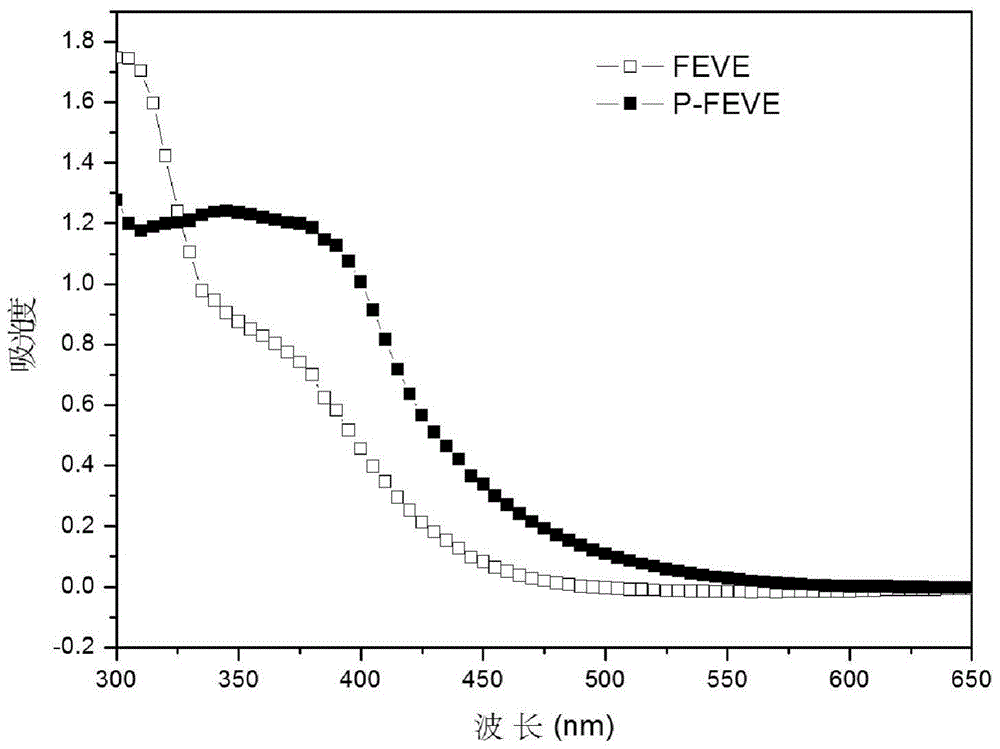

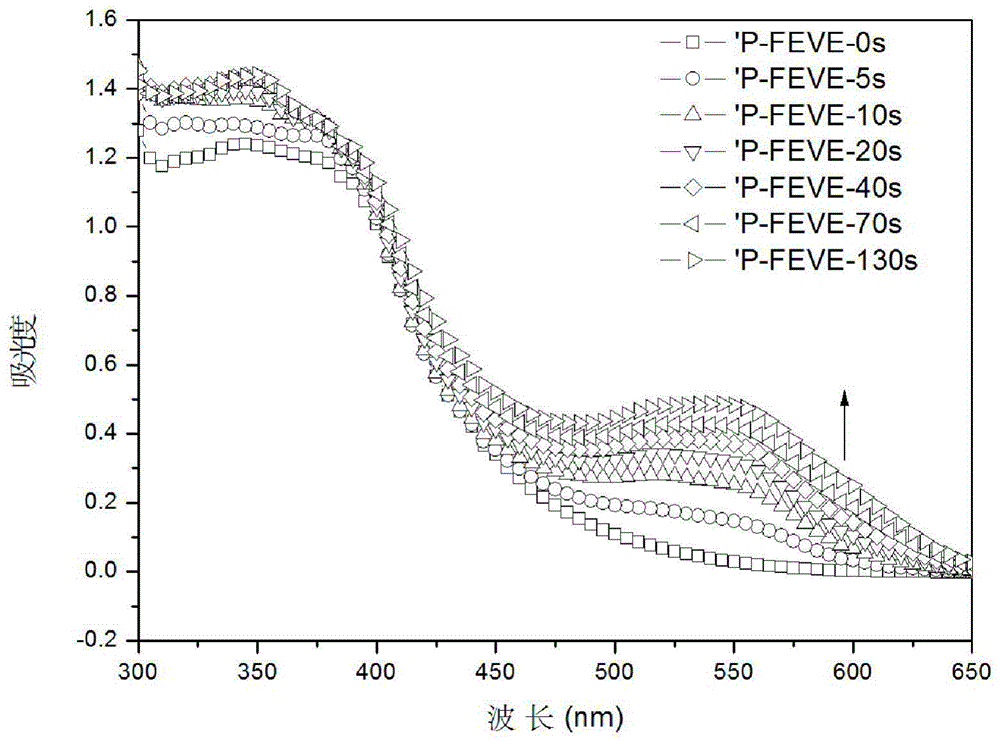

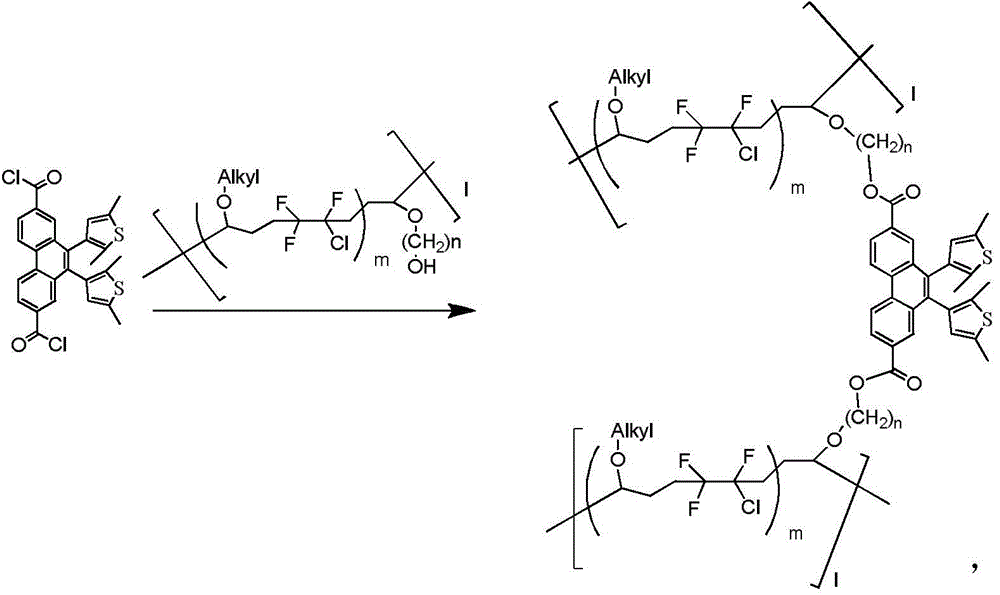

[0040] A kind of photochromic fluorocarbon resin, the fluorocarbon resin is grafted by diarylethene photochromic material 9,10-bis(2,5-dimethylthiophene)phenanthrene-2,7-diformyl chloride Prepared by modification, the preparation process includes the following raw materials: 100g fluorocarbon resin (50% solid content), 0.243g photochromic carboxylic acid material 9,10-bis(2,5-dimethylthiophene)phenanthrene-2 , 7-dicarboxylic acid, 500mL dichloromethane, 0.5mL oxalyl chloride, catalytic amount of N,N-dimethylformamide.

[0041] The specific steps of the preparation method are as follows:

[0042] (1) Preparation of the acid chloride solution of the color-changing functional group: referring to the literature (Junjie He et al, J. Mater. Chem. C, 2014, 2, 7531-7540), 0.243g of the photochromic carboxylic acid material 9,10-di( Add 2,5-dimethylthiophene)phenanthrene-2,7-dicarboxylic acid into a single-necked flask, add 50mL of dichloromethane, add 0.5mL of oxalyl chloride and cat...

Embodiment 2

[0046] A kind of photochromic fluorocarbon resin, the fluorocarbon resin is grafted by diarylethene photochromic material 9,10-bis(2,5-dimethylthiophene)phenanthrene-2,7-diformyl chloride Prepared by modification, the preparation process includes the following raw materials: 10g fluorocarbon resin (50% solid content), 0.243g photochromic carboxylic acid material 9,10-bis(2,5-dimethylthiophene)phenanthrene-2 , 7-dicarboxylic acid, 50mL dichloromethane, 0.5mL thionyl chloride, catalytic amount of N,N-dimethylformamide.

[0047] The specific steps of the preparation method are as follows:

[0048](1) Preparation of the acid chloride solution of the color-changing functional group: referring to the literature (Junjie He et al, J. Mater. Chem. C, 2014, 2, 7531-7540), 0.243g of the photochromic carboxylic acid material 9,10-di( Add 2,5-dimethylthiophene)phenanthrene-2,7-dicarboxylic acid into a single-necked flask, add 10 mL of dichloromethane, add 0.5 mL of thionyl chloride and a ...

Embodiment 3

[0052] A photochromic fluorocarbon resin coating film, which is obtained by curing the photochromic fluorocarbon resin prepared in Example 1 of the present invention with toluene diisocyanate. The raw materials include: 10 g of photochromic fluorocarbon resin, 0.38 g of toluene diisocyanate g. Its preparation method specifically comprises the following steps:

[0053] 1. Add 0.38 g of toluene diisocyanate to 10 g of the photochromic fluorocarbon resin, and stir evenly to obtain a mixed material;

[0054] 2. Vacuumize the resulting mixed material until the air bubbles are completely removed;

[0055] 3. The material obtained in step 2 is flat and clean glass or iron sheet to form a thin film by scraping, placed horizontally, and leveled to form a film;

[0056] 4. The coating film obtained in step 3 was ventilated, dried and cured for 7 days to obtain the photochromic fluorocarbon resin coating film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com