Preparation method of gradient porous polymer material

A polymer material and gradient porous technology, which is applied in the field of preparation of gradient porous polymer materials, can solve the problems of decreased mechanical properties of products, affecting product performance, and low thermal conductivity of polymers, so as to avoid degradation and reduce mechanical defects. , phase interface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of a polymer blend green body with a co-continuous phase structure

[0037] Using PCL and PLA as raw materials, according to the volume ratio of PCL and PLA = 40:60, the above raw materials are dried and premixed at normal pressure and room temperature, and then the premixed raw materials are mixed at 180 with a twin-screw extruder. ℃ melt blending and extruding to obtain a PCL / PLA blend green body with a two-phase continuous structure. cm.

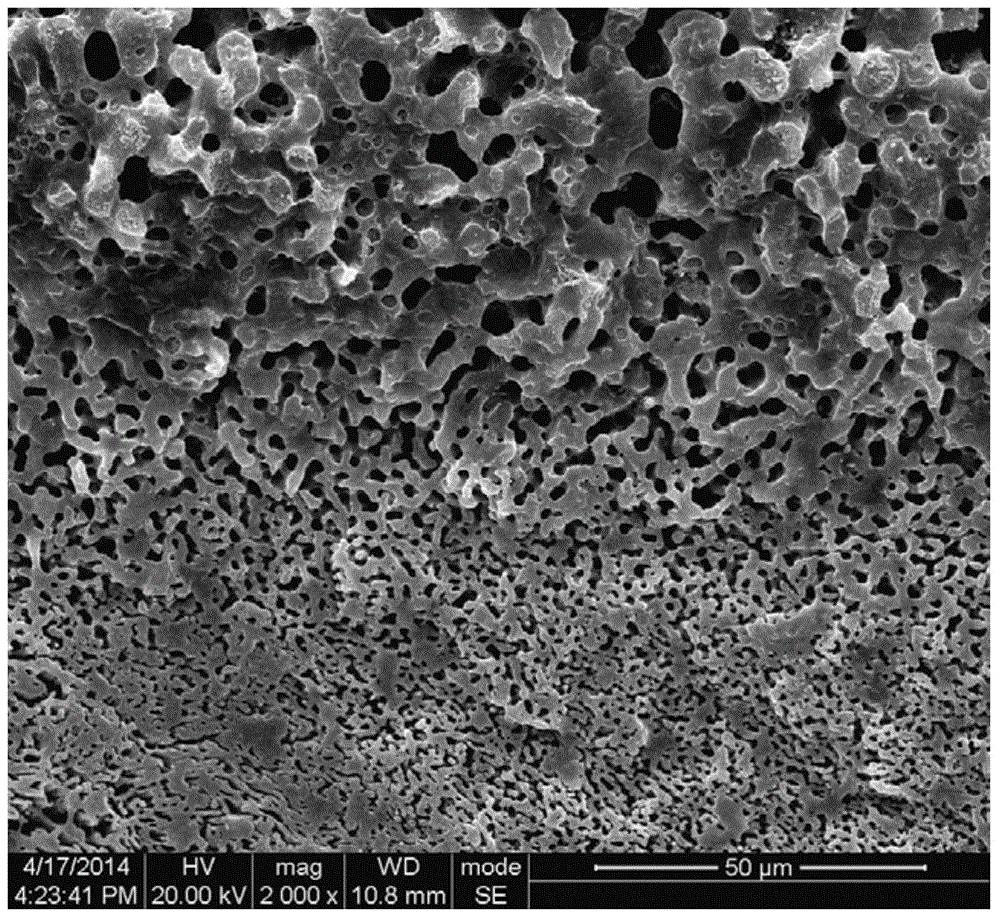

[0038] (2) Preparation of polymer blend body with gradient distribution of co-continuous phase size

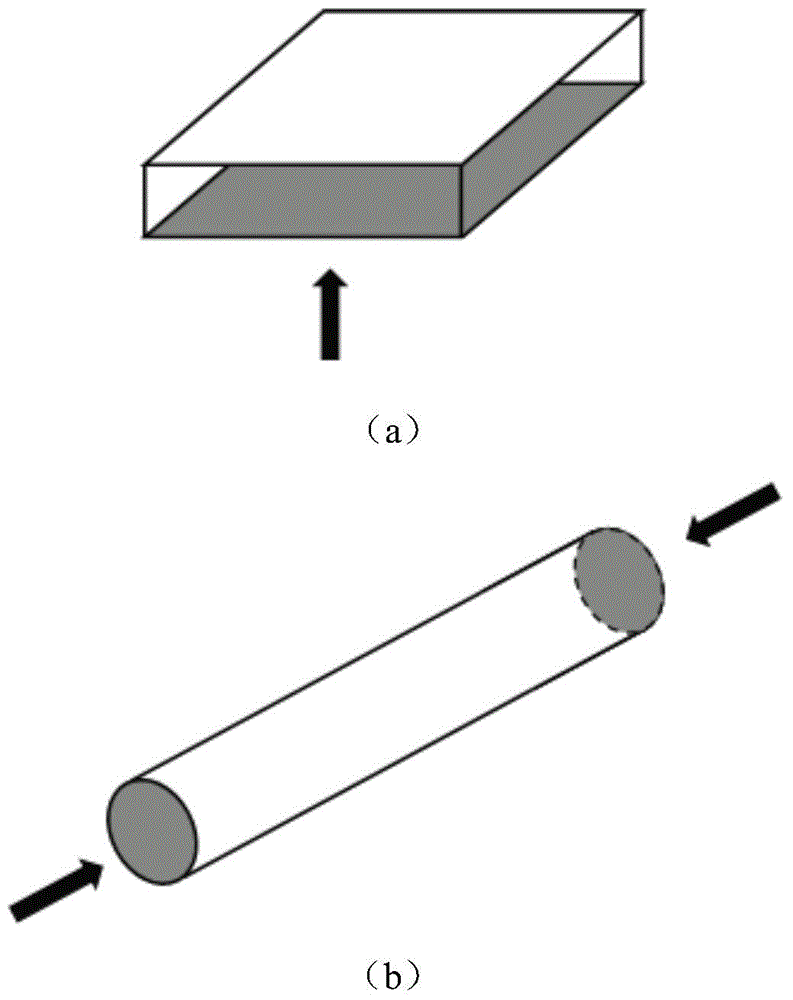

[0039] The lower surface (length * width = 1cm * 1cm) of the blend body prepared in step (1) is coated with a polytetrafluoroethylene film, and other surfaces are not coated, such as figure 1 As shown in (a), then place it on the support in the reactor, place the cladding side down, and pass CO into the reactor. 2 And the temperature of reactor is raised to 140 DEG C with the rate of temperature rise of 10 DEG C / ...

Embodiment 2

[0044] (1) Preparation of a polymer blend green body with a co-continuous phase structure

[0045] Using PCL and PLA as raw materials, according to the volume ratio of PCL and PLA = 50:50, the above raw materials are dried and premixed at normal pressure and room temperature, and then the premixed raw materials are mixed at 180 with a twin-screw extruder. ℃ melt blending and extruding to obtain a PCL / PLA blend green body with a two-phase continuous structure. cm.

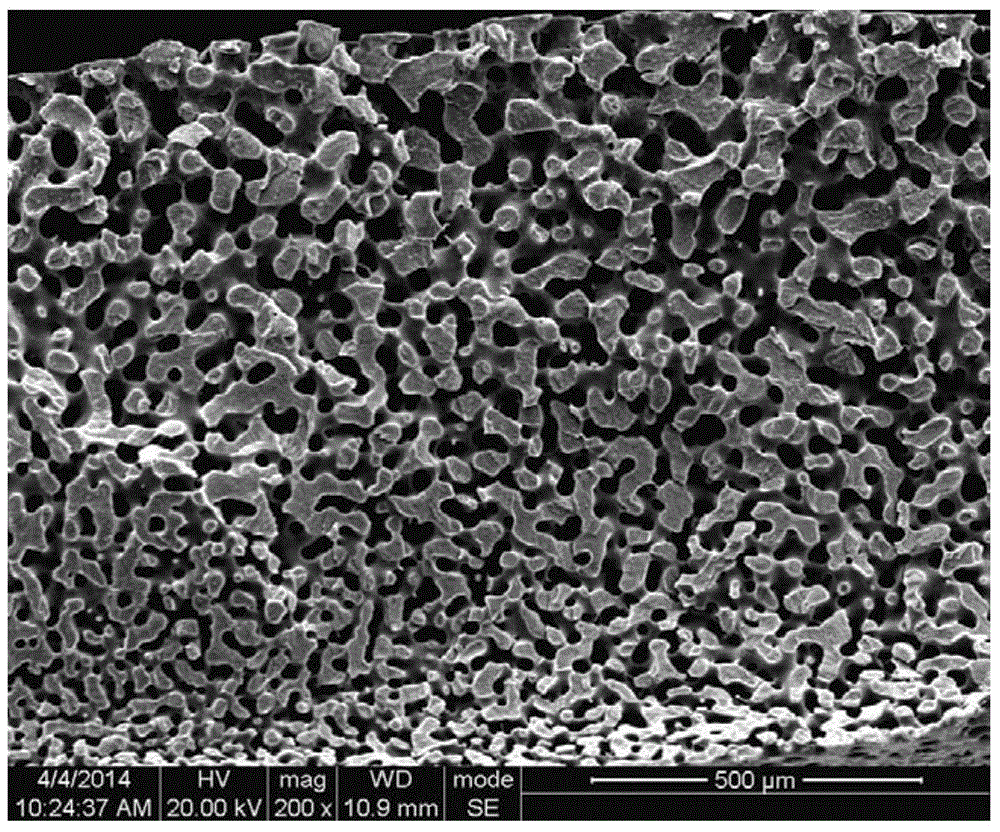

[0046] (2) Preparation of polymer blend body with gradient distribution of co-continuous phase size

[0047] Cover the surface of the blend body prepared in step (1) except the upper surface (length × width = 1cm × 1cm) with aluminum foil, and then place it on the support in the reaction kettle so that the uncoated surface faces upward placed, and CO was introduced into the reactor 2 And the temperature of reactor is raised to 120 DEG C with the rate of temperature rise of 15 DEG C / min, the pressure in the contro...

Embodiment 3

[0052] (1) Preparation of a polymer blend green body with a co-continuous phase structure

[0053] Using PCL and PLA as raw materials, according to the volume ratio of PCL and PLA = 50:50, the above raw materials are dried and premixed at normal pressure and room temperature, and then the premixed raw materials are mixed at 180 with a twin-screw extruder. ℃ melt blending and extruding to obtain a PCL / PLA blend green body with a two-phase continuous structure. cm.

[0054] (2) Preparation of polymer blend body with gradient distribution of co-continuous phase size

[0055] The upper surface (length × width = 1cm × 1cm) and the left side (width × thickness = 1cm × 0.2cm) of the blend body prepared in step (1) are wrapped with aluminum foil, and then placed in the reaction kettle on the bracket, so that the coated upper surface is placed upwards, and CO is introduced into the reactor 2 And the temperature of reactor is raised to 120 DEG C with the rate of temperature rise of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com