Active argon arc cladding Ni-based aluminum oxide-titanium diboride compound coating of coal ash and preparation method

A technology of argon arc cladding and composite coating, which is applied in coating, metal material coating process, etc., can solve problems such as increased overheating tendency, repeated heating of the cladding layer, cracks in the cladding layer, etc., and achieves cost reduction and economical Environmental protection application, the effect of improving hardness

Inactive Publication Date: 2015-05-20

LIAONING TECHNICAL UNIVERSITY +1

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the traditional argon arc cladding technology generally adopts the "small current, low voltage, thin layer multiple times" cladding method to prepare the cladding layer, but this method will cause the cladding layer to be heated repeatedly, and the overheating tendency will increase. Severe cracks or peeling inside

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] The invention provides a kind of fly ash active argon arc cladding Ni-based Al 2 o 3 -TiB 2 Composite coating and preparation method thereof, described preparation method comprises the steps:

[0027] The first step is the pretreatment of the matrix material;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Login to view more

Abstract

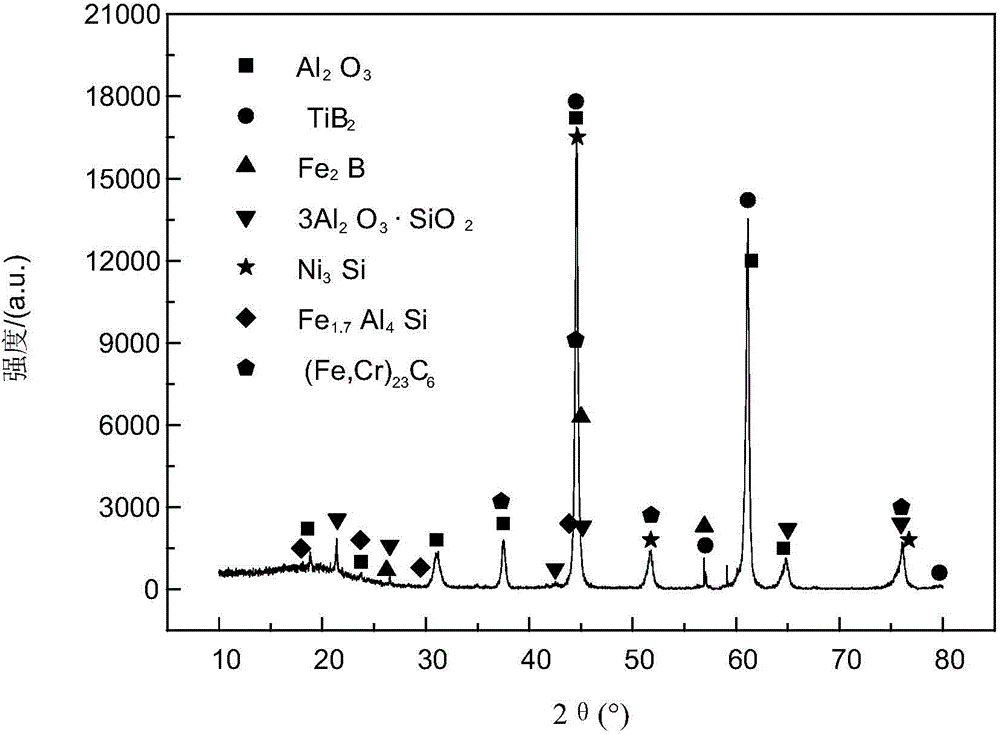

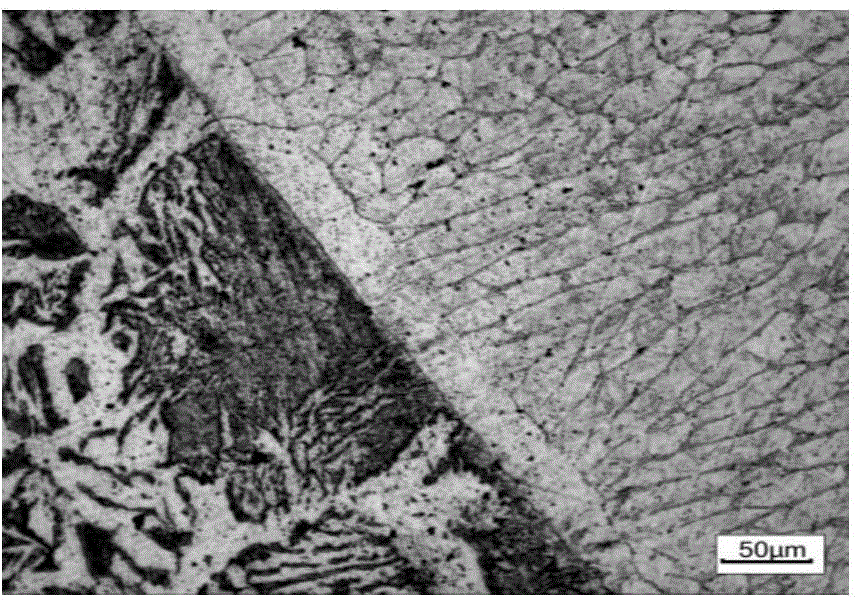

The invention discloses an active argon arc cladding Ni-based Al2O3-TiB2 compound coating of coal ash and a preparation method, and belongs to the technical field of tungsten inert gas tig welding. According to the invention, an A-TIG welding compound activating agent is prepared by taking high-alumina fly ash as a main raw material, and moreover, the compound activating agent is applied to an argon arc cladding process to prepare the active argon arc cladding Ni-based Al2O3-TiB2 compound coating on the surface of a Q235 steel matrix, so that the weld penetration is enlarged under an isosteric heat input condition, the surface hardness, wear resistance and corrosion resistance of the material are improved, and the service lives of mechanical parts are prolonged.

Description

technical field [0001] The invention belongs to the technical field of tungsten argon arc welding, and in particular relates to a kind of fly ash active argon arc cladding Ni-based Al 2 o 3 -TiB 2 Composite coating and method for its preparation. Background technique [0002] Active tungsten argon arc welding (referred to as A-TIG welding) technology is a rapidly developing and widely used welding technology in the welding industry at home and abroad. This technology can be used for welding almost all metal materials and can obtain high-quality welded joints , The weld penetration can reach 2 to 3 times that of traditional argon tungsten arc welding. At present, A-TIG welding has been widely used in aerospace, petrochemical, mechanical ship and transportation and other fields. The research on activator formula and welding process is the core of A-TIG welding, but most of the relevant research institutions at home and abroad have patented the composition and formula of ac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C23C24/10

CPCC23C24/103

Inventor 董世知马壮

Owner LIAONING TECHNICAL UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap