Construction method for reducing on-site cement cold regenerated mixture base cracks

A technology of cold recycled mixture and construction method, which is applied in the direction of on-site coagulation pavement, buildings, roads, etc., can solve the problems of subsidence of the pavement base and surface layer, affecting the driving quality and service life of the pavement, and avoid expansion. Uneven shrinkage, easy for operators to grasp, reducing the effect of excessive expansion agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

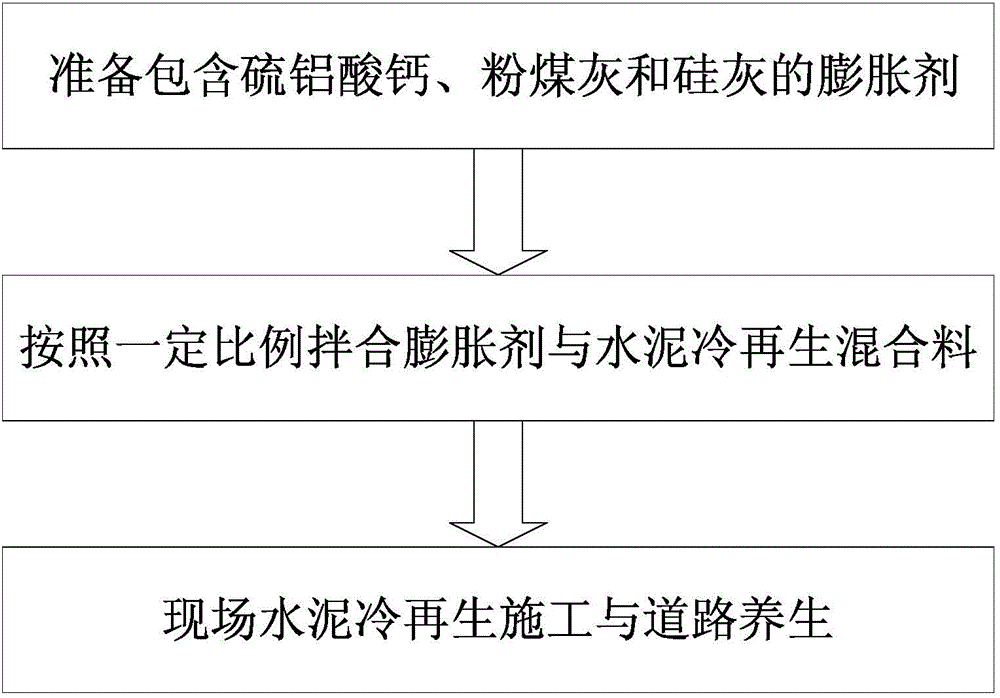

[0033] Such as figure 1 As shown, a construction method for reducing the cracks in the cement cold recycled mixture base course includes the following steps:

[0034] Step 1: Prepare the expansion agent used in the base construction of the on-site cement cold recycled mixture. The percentages of the components of the expansion agent added to the weight of the cement are: calcium sulfoaluminate 6%, fly ash 1%, silica fume 1% %, 0.5% iron powder, 0.1% aluminum oxide, 1% polypropylene fiber and 0.01% organic retarder.

[0035] Step 2: Mix the expansion agent described in step 1 with the on-site cement cold recycled mixture according to a certain ratio; wherein the cement is cement with low heat of hydration, such as: slag cement or fly ash cement, and its content accounts for The percentage by weight of the whole mixture is 0.5%, and the mixing time is 30s;

[0036] Step 3: Equip the cold recycling machine with special calcium sulfoaluminate expansion agent, fly ash and silica ...

example 2

[0052] A construction method for reducing cracks in the base course of cement cold recycled mixture on site, specifically comprising the following steps:

[0053] Step 1: Prepare the expansion agent used in the base construction of the on-site cement cold recycled mixture. The percentages of the addition of each component of the expansion agent to the weight of the cement are: calcium sulfoaluminate 8%, fly ash 1.5%, silica fume 1.5% %, iron powder 1.5%, aluminum oxide 1%, polypropylene fiber 1.5% and organic retarder 0.1%.

[0054] Step 2: Mix the expansion agent described in step 1 with the on-site cement cold recycled mixture according to a certain ratio; wherein the cement is cement with low heat of hydration, such as: slag cement or fly ash cement, and its content accounts for The percentage of total compound weight is 0.8%, and the mixing time is 30s;

[0055] Step 3: Equip the cold recycling machine with special calcium sulfoaluminate expansion agent, fly ash and silic...

example 3

[0072] A construction method for reducing cracks in the base course of cement cold recycled mixture on site, specifically comprising the following steps:

[0073] Step 1: Prepare the expansion agent used in the base construction of the on-site cement cold recycled mixture. The percentages of the addition of each component of the expansion agent to the weight of the cement are: calcium sulfoaluminate 7%, fly ash 1.2%, silica fume 1.2% %, 1% iron powder, 0.5% aluminum oxide, 1.2% polypropylene fiber and 0.05% organic retarder.

[0074] Step 2: Mix the expansion agent described in step 1 with the on-site cement cold recycled mixture according to a certain ratio; wherein the cement is cement with low heat of hydration, such as: slag cement or fly ash cement, and its content accounts for The percentage of total compound weight is 0.6%, and the mixing time is 30s;

[0075] Step 3: Equip the cold recycling machine with special calcium sulfoaluminate expansion agent, fly ash and sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com