Superheated steam combined boiler and superheated steam making method

A superheated steam and boiler technology, applied in the field of boilers, can solve the problems that different time periods cannot be completely matched, the superheated steam time is long, and the energy consumption is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

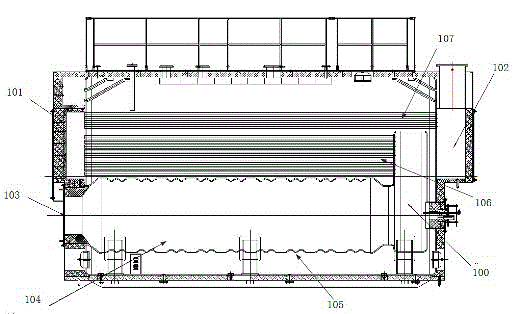

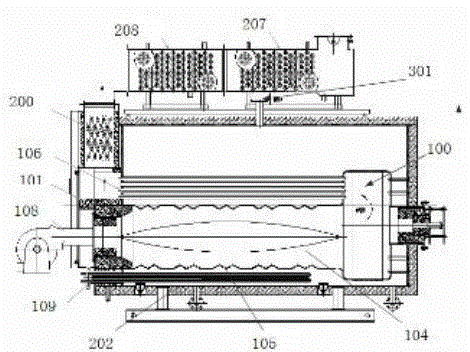

[0019] figure 1 It is a side sectional schematic diagram of a traditional dry-back two-pass shell boiler. Refer to the following figure 1 The steam production process of a conventional boiler is explained.

[0020] figure 1 It is a schematic diagram of the side section of a traditional dry-back two-pass shell boiler. In the figure, 100: combustion chamber, 101: front smoke box, 102: smoke box, 103: burner interface, 104: furnace, 105: corrugated furnace, 106: convection tube bundle.

[0021] The following is the steam making process in a traditional boiler. The burner connected to the burner interface 103 ignites the gas or oil and burns it in the furnace 104. In order to prevent the furnace from expanding due to heat, it is generally designed as a corrugated furnace 105 that can relieve thermal expansion. The burned flue gas passes through the combustion chamber 100 enters the convection tube bundle 106, and through the flue gas flowing back and forth, the water in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com