Ultra-low nitrogen oxide combustion apparatus using internal recirculation of combustion gas and method therefor

A technology for nitrogen oxides and combustion equipment, which is applied in combustion methods, combustion equipment, and combustion using various fuels, etc., can solve problems such as large space requirements, achieve the effects of stabilizing the flame, simplifying settings, and suppressing overheating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

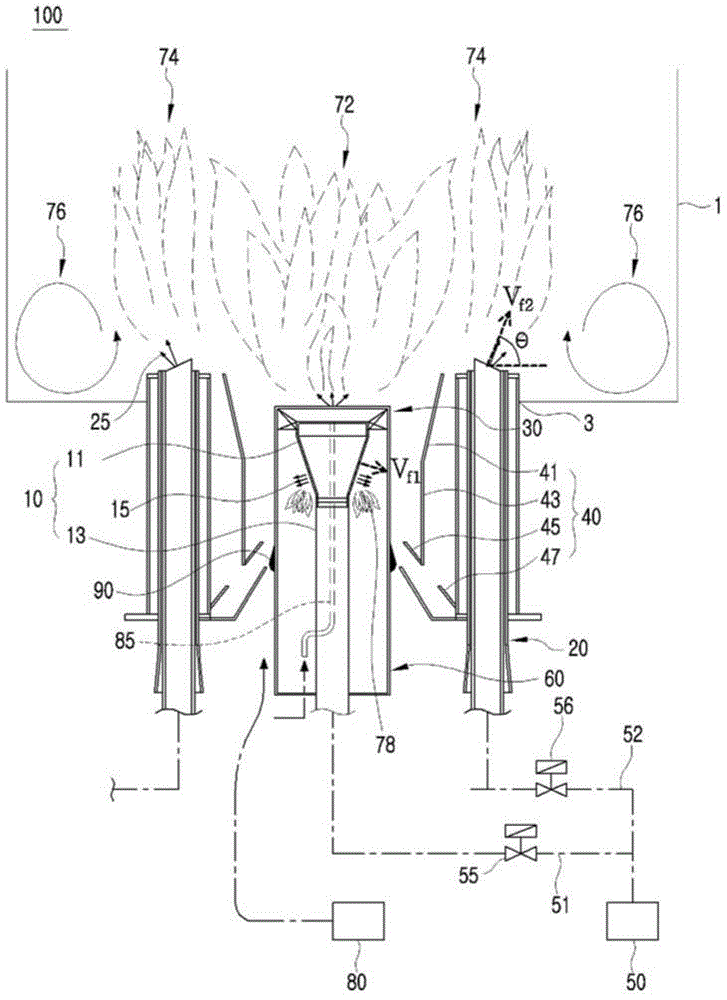

[0062] The above objects, features and other advantages of the present invention will become more apparent by describing in detail preferred embodiments of the present invention with reference to the accompanying drawings. The described embodiments are provided illustratively for explaining the invention, and do not limit the technical scope of the invention.

[0063] The constituent elements constituting the ultra-low nitrogen oxide combustion equipment of the present invention can be used as a whole or separately. Furthermore, depending on the form of use, some of the constituent elements may be omitted.

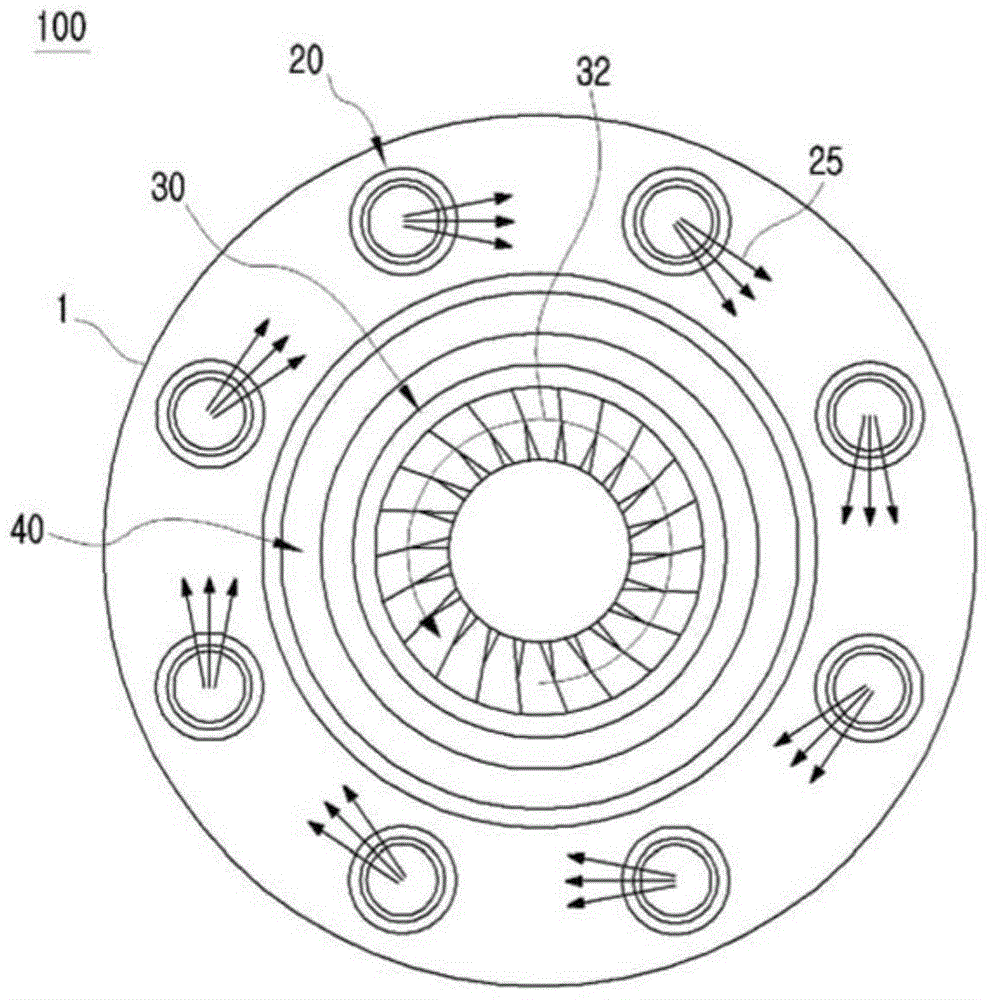

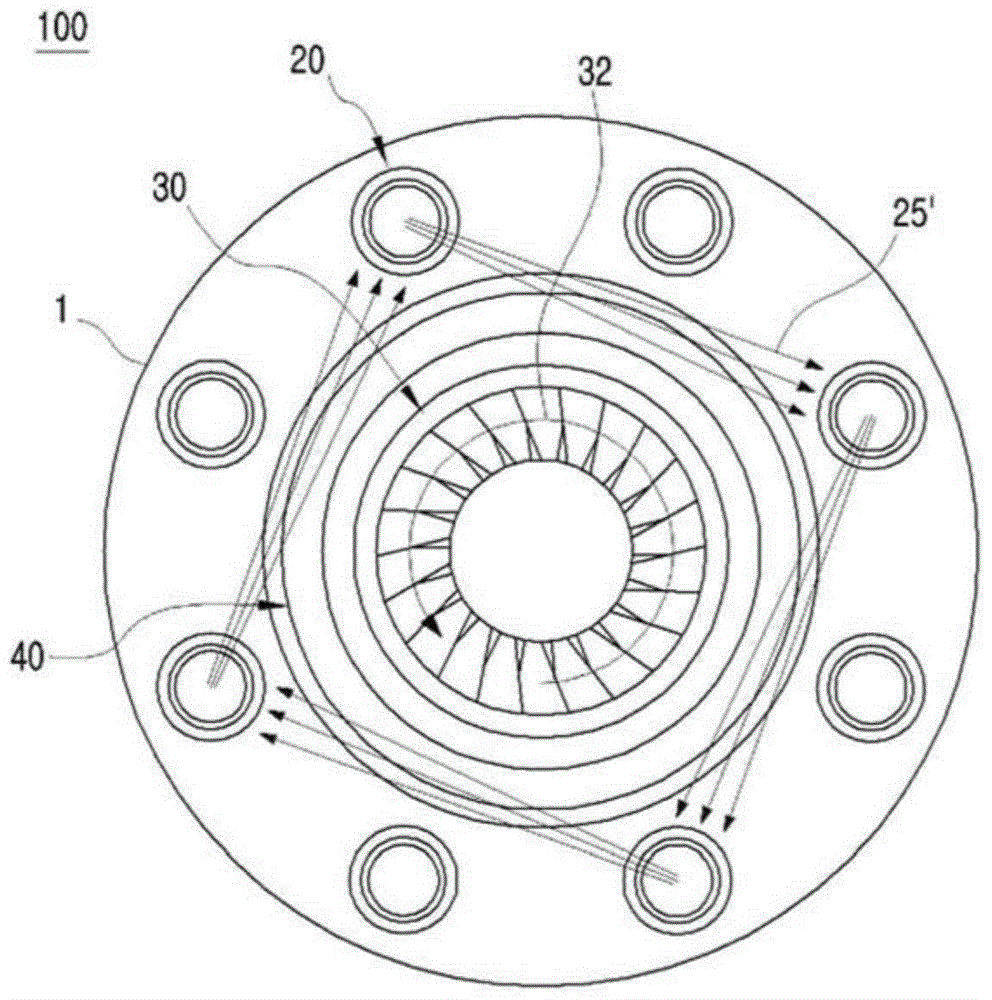

[0064] Hereinafter, an ultra-low nitrogen oxide combustion device according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0065] Explanation of the overall structure of ultra-low nitrogen oxide combustion equipment

[0066] First, refer to figure 1 , the overall structure of the ultra-low nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com