Device and method for evaluating directions and depths of metal cracks by using ultrasonic electromagnetic principle

An ultrasonic electromagnetic and crack technology, which is used in measuring devices, material analysis by electromagnetic means, material magnetic variables, etc., can solve the problem of inability to evaluate the crack direction, and achieve the effect of rapid evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

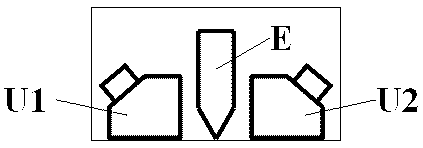

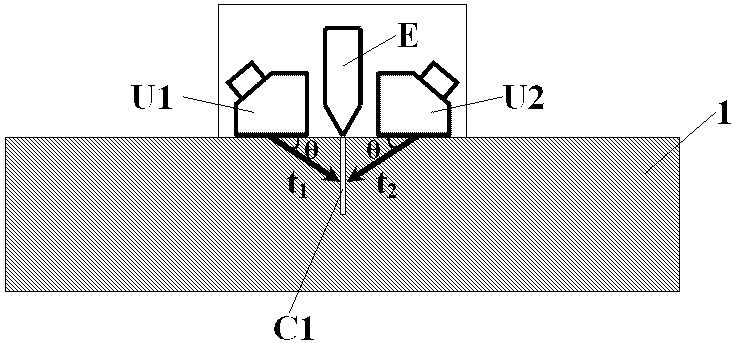

[0022] The first embodiment, such as figure 1 As shown, the device for evaluating the direction and depth of metal cracks using the ultrasonic electromagnetic principle adopts an eddy current detection point probe E and two ultrasonic detection oblique probes U1, U2 to make a combined probe scanning device, and the two ultrasonic detection oblique probes U1, U2 The incident angle θ, frequency, material, and shape of U2 are the same, and the incident angle θ is a fixed value. The two ultrasonic testing oblique probes U1 and U2 are mirror-symmetrically fixed, so that the ultrasonic waves emitted by the two ultrasonic testing oblique probes U1 and U2 are mirror-symmetrical. Intersect; the eddy current detection point probe E is placed in the middle of the two ultrasonic detection angle probes U1 and U2.

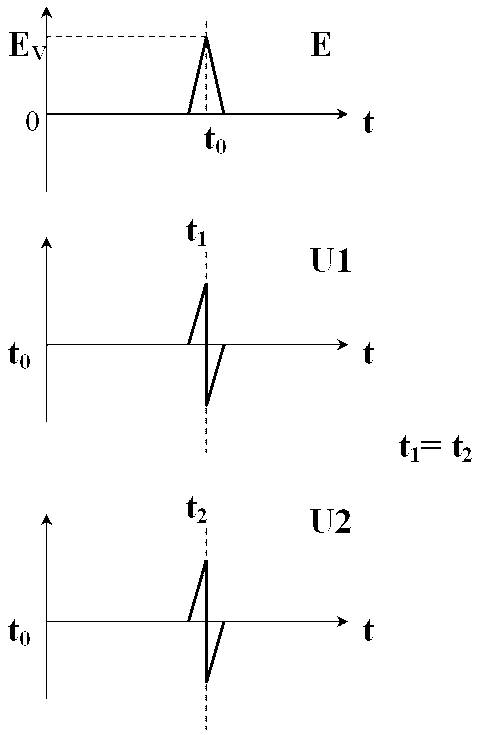

[0023] The first embodiment, such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the method of evaluating the direction and depth of metal cracks using the ultras...

no. 2 example

[0028] Second embodiment, such as Image 6 As shown, the device for evaluating the direction and depth of metal cracks by using the ultrasonic electromagnetic principle, further, the array eddy current detection probe AE is used to replace the eddy current detection point probe E in the combined probe scanning device. The method of evaluating the trend and depth of metal cracks using ultrasonic electromagnetic principles, further, after performing steps a and b, in step c, when the array eddy current detection probe AE just reaches the top of the crack opening, the crack eddy current induction signal amplitude E V reaches the maximum value, according to the crack eddy current induction signal amplitude E obtained in step a V , phase and crack depth calibration relationship function to calculate the crack depth equivalent relative to the standard artificial crack; When the surface trend of the crack in material 1 is not perpendicular to the scanning direction of the combined p...

no. 3 example

[0029] In the third embodiment, the method for evaluating the trend and depth of metal cracks using ultrasonic electromagnetic principles, further, after performing step a, step b, and step c, in step d, according to the frequency of the ultrasonic detection angle probe U1, U2 and the wafer The area is calculated to obtain the diffusion angle of the ultrasonic testing angled probes U1 and U2, combined with the time value t of the echo signal of the two ultrasonic testing angled probes U1 and U2 obtained in step a when encountering a crack 1 , t 2 A relatively accurate crack inclination angle can be obtained by calculating the calibration relationship function with the inclination angle of the crack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com